A kind of nb-si intermetallic compound bar and preparation method thereof

An intermetallic compound and rod technology, which is applied in the field of intermetallic compound preparation, can solve the problem that the superior properties of Nb-Si intermetallic compounds cannot be fully exerted, the melting point and high temperature mechanical properties of Nb-Si intermetallic compounds are reduced, and they are not perfect. Nb-Si intermetallic compounds and other problems, to achieve the effect of reducing oxygen content, reducing sintering temperature, and uniform composition distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

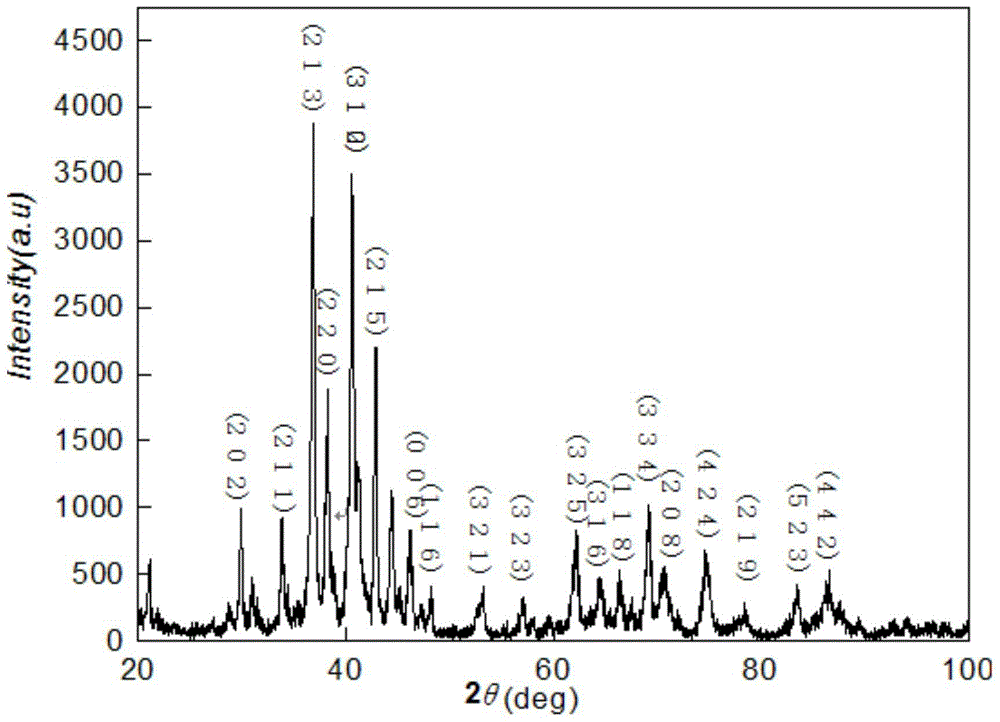

Image

Examples

Embodiment 1

[0026] In this embodiment, the Nb-Si intermetallic compound rod is made of the following atomic percentages of raw materials: 40% silicon, and the balance being niobium and unavoidable impurities.

[0027] The method for preparing the Nb-Si intermetallic compound rod in this embodiment comprises the following steps:

[0028] Step 1. Put silicon powder and niobium powder in a ball mill, use absolute ethanol as a dispersant, and ball mill for 25 hours at a speed of 350 rpm and a ball-to-material ratio of 8:1 by mass ratio. Dry to obtain mixed powder; the volume of the absolute ethanol is 0.8 times the sum of the mass of silicon powder and niobium powder, wherein the unit of volume is mL, and the unit of mass is g; the drying temperature is preferably 95°C ; Preferably, the mass purity of the silicon powder is not less than 99%, and the mass purity of the niobium powder is not less than 99%;

[0029] Step 2. Compress the mixed powder described in step 1 to obtain a billet, and t...

Embodiment 2

[0034] The Nb-Si intermetallic compound rod in this embodiment is made of the following atomic percentages: silicon 37%, the balance being niobium and unavoidable impurities.

[0035] The method for preparing the Nb-Si intermetallic compound rod in this embodiment comprises the following steps:

[0036] Step 1. Put silicon powder and niobium powder in a ball mill, use absolute ethanol as a dispersant, and ball mill for 30 hours at a rotational speed of 300rpm and a ball-to-material ratio of 10:1 by mass. Dry to obtain mixed powder; the volume of the absolute ethanol is equal to the sum of the mass of silicon powder and niobium powder, wherein the unit of volume is mL, and the unit of mass is g; the drying temperature is preferably 90°C; preferably Specifically, the mass purity of the silicon powder is not less than 99%, and the mass purity of the niobium powder is not less than 99%;

[0037] Step 2. Compress the mixed powder described in step 1 to obtain a billet, and then pl...

Embodiment 3

[0042] In this embodiment, the Nb-Si intermetallic compound rod is made of the following atomic percentages of raw materials: silicon 43%, the balance being niobium and unavoidable impurities.

[0043] The method for preparing the Nb-Si intermetallic compound rod in this embodiment comprises the following steps:

[0044] Step 1. Put silicon powder and niobium powder in a ball mill, use absolute ethanol as a dispersant, and ball mill for 20 hours at a speed of 400 rpm and a ball-to-material ratio of 5:1 by mass ratio. Dry to obtain mixed powder; the volume of the absolute ethanol is 0.5 times the sum of the mass of silicon powder and niobium powder, wherein the unit of volume is mL, and the unit of mass is g; the drying temperature is preferably 100°C ; Preferably, the mass purity of the silicon powder is not less than 99%, and the mass purity of the niobium powder is not less than 99%;

[0045] Step 2. Compress the mixed powder described in step 1 to obtain a billet, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com