High-strength addition-type mould rubber composition and preparation method thereof

A composition and additive molding technology, which is applied in the field of mold glue, can solve the problems of reducing mold glue turning times and quality, reducing mold glue heat shrinkage, and low tear strength, so as to improve mold turning quality and improve The effect of turning over times and improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

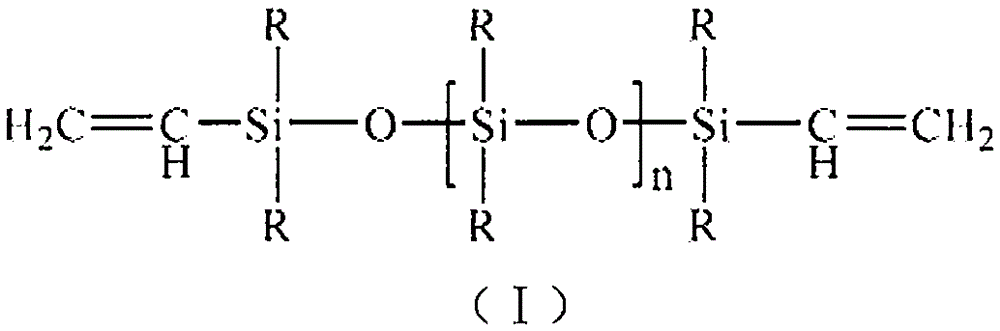

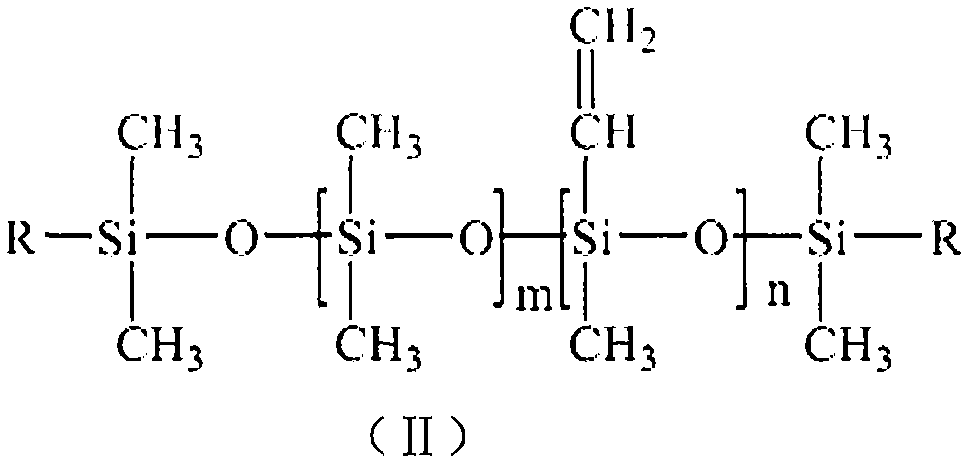

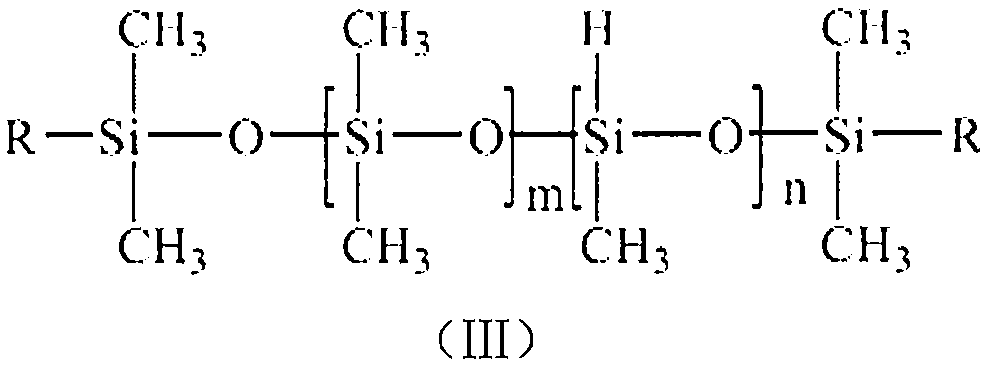

Method used

Image

Examples

Embodiment 1

[0037] Base rubber preparation: 60 parts of 10000mPa·s vinyl-terminated silicone oil with a specific surface area of 300m 2 Add 32 parts / g of fumed silica (Japan Tokuyama QS-30), 8 parts of hexamethylsilazane, and 1.6 parts of water into the kneader, stir at room temperature for 1 hour, then raise the temperature to 150°C and continue stirring After 2 hours, finally add 40 parts of 10000mPa·s vinyl-terminated silicone oil to dilute, and obtain the base rubber after cooling.

[0038] Preparation of component A: Take 87.5 g of the above base glue, add 0.1 g of platinum catalyst (platinum content is 3000 ppm), and stir evenly.

[0039] Preparation of component B: Take 44.6g of the above base glue, add vinyl silicone resin (the amount of vinyl groups is 4.44×10 -4 mol / g) 20g, high-concentration vinyl silicone oil (vinyl group content 1.35×10 -3 mol / g) 5g, hydrogen-containing silicone oil containing only hydrogen in the side chain (SiH group amount 8.0×10 -3 mol / g) 14g, hydrog...

Embodiment 2

[0042] Base rubber preparation: 60 parts of 10000mPa·s vinyl-terminated silicone oil with a specific surface area of 300m 2 Add 30 parts / g of fumed silica (Japan Tokuyama QS-30), 7.5 parts of hexamethylsilazane, and 1.5 parts of water into the kneader, stir at room temperature for 1 hour, then raise the temperature to 150°C and continue stirring After 2 hours, finally add 40 parts of 10000mPa·s vinyl-terminated silicone oil to dilute, and obtain the base rubber after cooling.

[0043] Preparation of component A: Take 77.5 g of the above base glue, add 0.1 g of platinum catalyst (platinum content is 3000 ppm), and stir evenly.

[0044] Preparation of component B: Take 52.5g of the above base glue, add vinyl silicone resin (the amount of vinyl groups is 4.44×10 -4 mol / g) 10g, high-concentration vinyl silicone oil (vinyl group content 1.35×10 -3 mol / g) 5g, hydrogen-containing silicone oil containing only hydrogen in the side chain (SiH group amount 8.0×10 -3 mol / g) 9.1g, hyd...

Embodiment 3

[0047] Base rubber preparation: 60 parts of 10000mPa·s vinyl-terminated silicone oil with a specific surface area of 300m 2 Add 32 parts / g of fumed silica (Japan Tokuyama QS-30), 8 parts of hexamethylsilazane, and 1.6 parts of water into the kneader, stir at room temperature for 1 hour, then raise the temperature to 150°C and continue stirring After 2 hours, finally add 40 parts of 10000mPa·s vinyl-terminated silicone oil to dilute, and obtain the base rubber after cooling.

[0048] Preparation of component A: Take 87.5 g of the above base glue, add 0.1 g of platinum catalyst (platinum content is 3000 ppm), and stir evenly.

[0049] Preparation of component B: Take 44.6g of the above base glue, add vinyl silicone resin (the amount of vinyl groups is 4.44×10 -4 mol / g) 20g, high concentration vinyl silicone oil (vinyl group content 4×10 -4 mol / g) 5g, cross-linking agent hydrogen-containing silicone oil (SiH group content 8.0×10-3mol / g) 14g, only hydrogen-containing chain ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com