Novel thermosetting epoxy resin used for carbon fiber composite material

A technology of epoxy resin and composite materials, applied in the field of polymer materials, can solve the problems of poor compatibility/permeability of resin and carbon fiber, short shelf life, low molding efficiency, etc., and achieve excellent outdoor environmental aging resistance and good performance Compatibility, permeability, and high molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

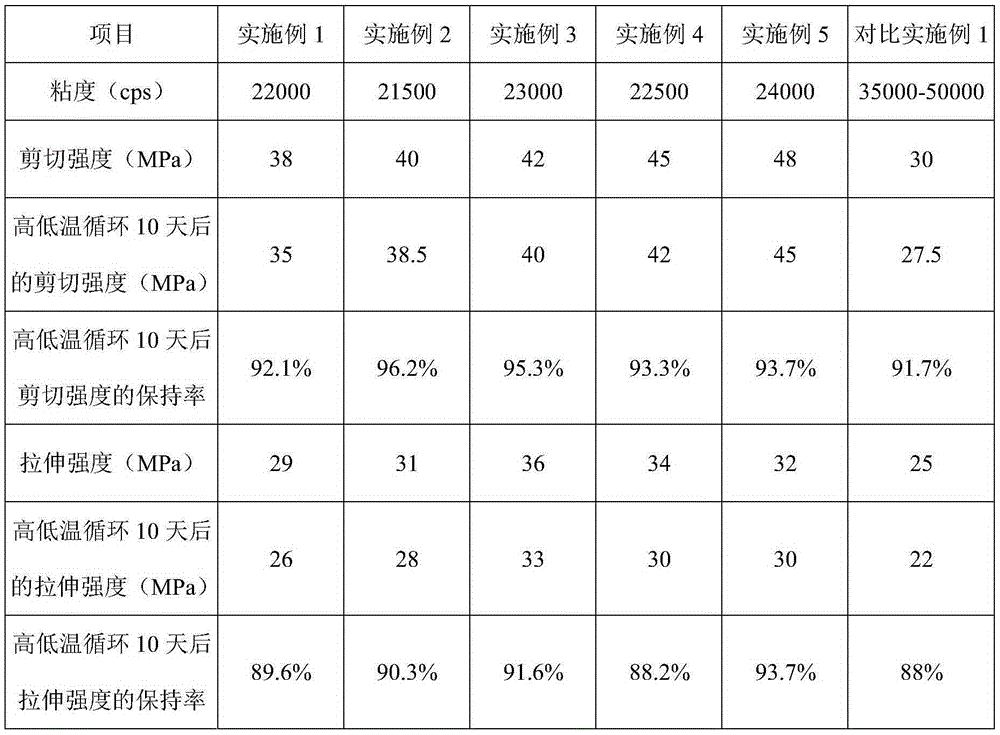

Examples

Embodiment 1

[0035] A new type of thermosetting epoxy resin for carbon fiber composite materials, including components and their parts: 40 parts of E51 / polybutadiene rubber polymer, 60 parts of hybrid epoxy resin, 0.2 parts of graphene, SBM / MAM copolymer 8 parts, ETBN toughening agent 4 parts, dispersant 0.1 part, nano-sized attapulgite 2 parts, hydrophilic fumed silica 3 parts, wetting agent 0.5 parts, micron-sized dicyandiamide 12 parts 1 part, 1 part of latent accelerator, 0.6 part of silane coupling agent. Wherein, the specific surface area of the nano-scale attapulgite is 36m 2 / g, the latent accelerator is micron dicyandiamide.

[0036] Adopt following preparation method to obtain:

[0037] Step S1: Add E51 / polybutadiene rubber polymer, hybrid epoxy resin, graphene, SBM / MAM into a stainless steel reaction kettle equipped with agitator, thermostat, reflux condenser, feeding and nitrogen filling device The copolymer, the toughening agent and the dispersant are heated up to 80°C, ...

Embodiment 2

[0042]A new type of thermosetting epoxy resin for carbon fiber composite materials, including components and their parts: 45 parts of E51 / polybutadiene rubber polymer, 55 parts of hybrid epoxy resin, and 0.25 parts of reinforced graphene , 6 parts of SBM / MAM copolymer, 7 parts of ETBN toughening agent, 0.25 parts of dispersant, 5 parts of nano-scale attapulgite, 4 parts of hydrophilic fumed silica, 0.1 part of wetting agent, micron dicyandiamide 10 parts of amine, 2 parts of latent accelerator, 0.5 part of silane coupling agent. Wherein, the specific surface area of the nano-scale attapulgite is 30m 2 / g, the latent accelerator is micron dicyandiamide.

[0043] Adopt following preparation method to obtain:

[0044] Step S1: Add E51 / polybutadiene rubber polymer, hybrid epoxy resin, graphene, SBM / MAM into a stainless steel reaction kettle equipped with agitator, thermostat, reflux condenser, feeding and nitrogen filling device The copolymer, the toughening agent and the dis...

Embodiment 3

[0048] A new type of thermosetting epoxy resin for carbon fiber composite materials, including components and their parts: 50 parts of E51 / polybutadiene rubber polymer, 50 parts of hybrid epoxy resin, and 0.3 parts of reinforced graphene , 5 parts of SBM / MAM copolymer, 6 parts of ETBN toughening agent, 0.3 parts of dispersant, 3 parts of nano-scale attapulgite, 2 parts of hydrophilic fumed silica, 0.2 part of wetting agent, micron dicyandiamide 6.5 parts of amine, 3 parts of latent accelerator, 0.8 part of silane coupling agent. Wherein, the specific surface area of the nano-scale attapulgite is 18m 2 / g, the latent accelerator is micron dicyandiamide.

[0049] Adopt following preparation method to obtain:

[0050] Step S1: Add E51 / polybutadiene rubber polymer, hybrid epoxy resin, graphene, SBM / MAM into a stainless steel reaction kettle equipped with agitator, thermostat, reflux condenser, feeding and nitrogen filling device The copolymer, the toughening agent and the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com