A 3D printing ceramic process

A ceramic technology and 3D printing technology, applied in the field of ceramic manufacturing, can solve the problems of difficulty in improving the hardness and strength of castings, weak bonding of powdered binders, loose structure of castings, etc., and achieve the promotion of hardness and strength. Evaporative removal and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

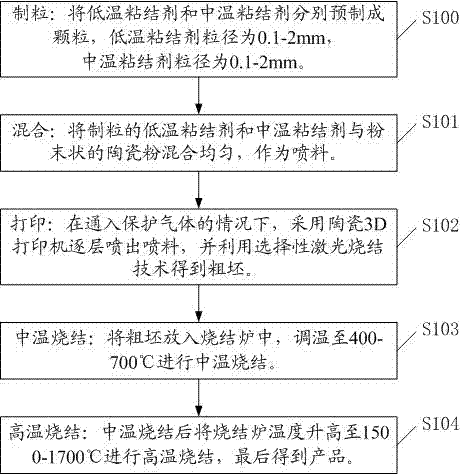

Method used

Image

Examples

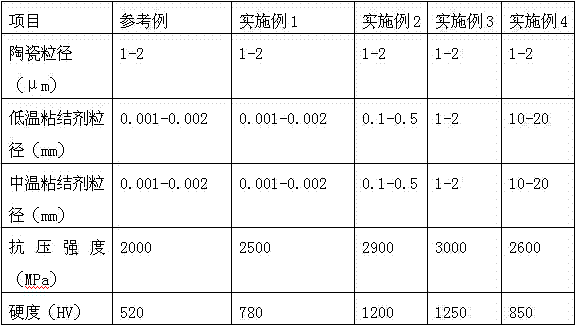

Embodiment 1

[0062] Weigh the spray material by percentage: 96% ceramic powder, 2% low-temperature binder and 2% medium-temperature binder, wherein the particle size of the ceramic powder, low-temperature binder and medium-temperature binder is 1-2 μm.

[0063] Mix ceramic powder, granular low-temperature binder and medium-temperature binder evenly, and pour them into the nozzle of the printer.

[0064] In the case of feeding the protective gas, the ceramic 3D printer is used to spray the material layer by layer, and the rough blank is obtained by using the selective laser sintering technology;

[0065] Put the rough billet into the sintering furnace, adjust the temperature to 600°C for medium temperature sintering;

[0066] After medium-temperature sintering, the temperature of the sintering furnace is raised to 1650°C for high-temperature sintering, and finally the product is obtained.

Embodiment 2

[0068] Weigh the spray material according to the percentage: 96% ceramic powder, 2% low-temperature binder and 2% medium-temperature binder, of which the ceramic powder is 1-2μm, and the particle size of the low-temperature binder is 0.1-0.5 through the granulation process The particle size of mm and medium temperature binder is 0.1-0.5mm.

[0069] Mix ceramic powder, granular low-temperature binder and medium-temperature binder evenly, and pour them into the nozzle of the printer.

[0070] In the case of feeding the protective gas, the ceramic 3D printer is used to spray the material layer by layer, and the rough blank is obtained by using the selective laser sintering technology;

[0071] Put the rough billet into the sintering furnace, adjust the temperature to 600°C for medium temperature sintering;

[0072] After medium-temperature sintering, the temperature of the sintering furnace is raised to 1650°C for high-temperature sintering, and finally the product is obtained. ...

Embodiment 3

[0074] Weigh the spray material according to the percentage: 96% ceramic powder, 2% low-temperature binder and 2% medium-temperature binder, of which the ceramic powder is 1-2μm, and the particle size of the low-temperature binder is 1-2mm through the granulation process And the particle size of medium temperature binder is 1-2mm.

[0075] Mix ceramic powder, granular low-temperature binder and medium-temperature binder evenly, and pour them into the nozzle of the printer.

[0076] In the case of feeding the protective gas, the ceramic 3D printer is used to spray the material layer by layer, and the rough blank is obtained by using the selective laser sintering technology;

[0077] Put the rough billet into the sintering furnace, adjust the temperature to 600°C for medium temperature sintering;

[0078] After medium-temperature sintering, the temperature of the sintering furnace is raised to 1650°C for high-temperature sintering, and finally the product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com