Negative thermal expansion ceramic material ScxIn2-xW3O12 and preparation method thereof

A technology of scxin2-xw3o12 and ceramic materials, which is applied in the field of negative thermal expansion ceramic materials ScxIn2-xW3O12 and its preparation, can solve the problems of high synthesis cost and high price, and achieve low cost, compact ceramic structure, wide application value and application prospect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Synthesis of negative thermal expansion material ScInW 3 o 12 , to analyze pure Sc 2 o 3 、In 2 o 3 and WO 3 Powder is raw material, according to molar ratio Sc 2 o 3 : In 2 o 3 : WO 3 =1:1:3 Weigh the raw materials, mix them in alcohol, and ball mill them for 12 hours. After ball milling, dry the raw materials in an oven at 60°C, and then grind them with an agate mortar for 0.5 hours.

[0022] (2) Add polyvinyl alcohol (PVA) accounting for 2% of the total mass to the uniformly ball-milled material in step (1), grind to make the mixture uniform, and then cold-press at 50 MPa to form a tablet.

[0023] (3) The material after tableting in step (2) was degummed at 500°C for 0.5h, sintered at 950°C for 24h, and cooled naturally with the furnace to obtain the negative thermal expansion material ScInW 3 o 12 ceramics.

Embodiment 2

[0025] (1) Synthesis of negative thermal expansion material Sc 1.1 In 0.9 W 3 o 12 , to analyze pure Sc 2 o 3 、In 2 o 3 and WO 3 Powder is raw material, according to molar ratio Sc 2 o 3 :In 2 o 3 : WO 3=1.1:0.9:3 Weigh the raw materials, mix them in alcohol, and then ball mill them for 18 hours. After ball milling, dry the raw materials in an oven at 80°C, and then grind them with an agate mortar for 0.8 hours.

[0026] (2) Add polyvinyl alcohol (PVA) accounting for 3% of the total mass to the uniformly ball-milled material in step (1), grind to make the mixture uniform, and then cold-press at 100 MPa to form a tablet.

[0027] (3) The material after tableting in step (2) was degummed at 500°C for 0.8h, sintered at 1050°C for 18h, and cooled naturally with the furnace to obtain the negative thermal expansion material Sc 1.1 In 0.9 W 3 o 12 ceramics.

Embodiment 3

[0029] (1) Synthesis of negative thermal expansion material Sc 1.2 In 0.8 W 3 o 12 , to analyze pure Sc 2 o 3 、In 2 o 3 and WO 3 Powder is raw material, according to molar ratio Sc 2 o 3 :In 2 o 3 : WO 3 =1.2:0.8:3 Weigh the raw materials, mix them in alcohol, and then ball mill them for 24 hours. After ball milling, dry the raw materials in an oven at 100°C, and then grind them with an agate mortar for 1 hour.

[0030] (2) Add polyvinyl alcohol (PVA) accounting for 5% of the total mass to the uniformly ball-milled material in step (1), grind to make the mixture uniform, and then cold-press at 150 MPa to form a tablet.

[0031] (3) The material after tableting in step (2) was degummed at 500°C for 1 hour, sintered at 1150°C for 12 hours, and cooled naturally with the furnace to obtain the negative thermal expansion material Sc 1.1 In 0.9 W 3 o 12 ceramics.

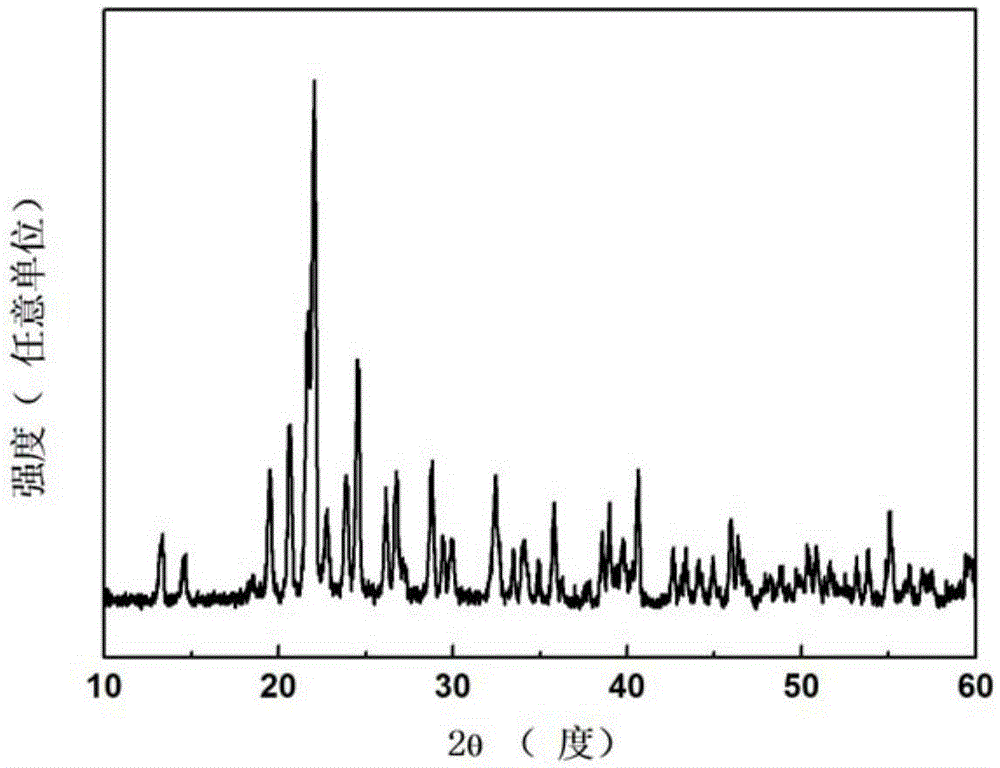

[0032] Down figure 1 is the preparation of ScInW 3 o 12 The XRD pattern of the ceramic, from the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com