Spherical graphite purification furnace

A spherical graphite and spherical technology, applied in the field of spherical graphite purification furnace, can solve the problems of simple structure, loss of parts, and low cost of the purification furnace, and achieve the effects of high purification accuracy, improved accuracy, and convenient collection or pouring out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

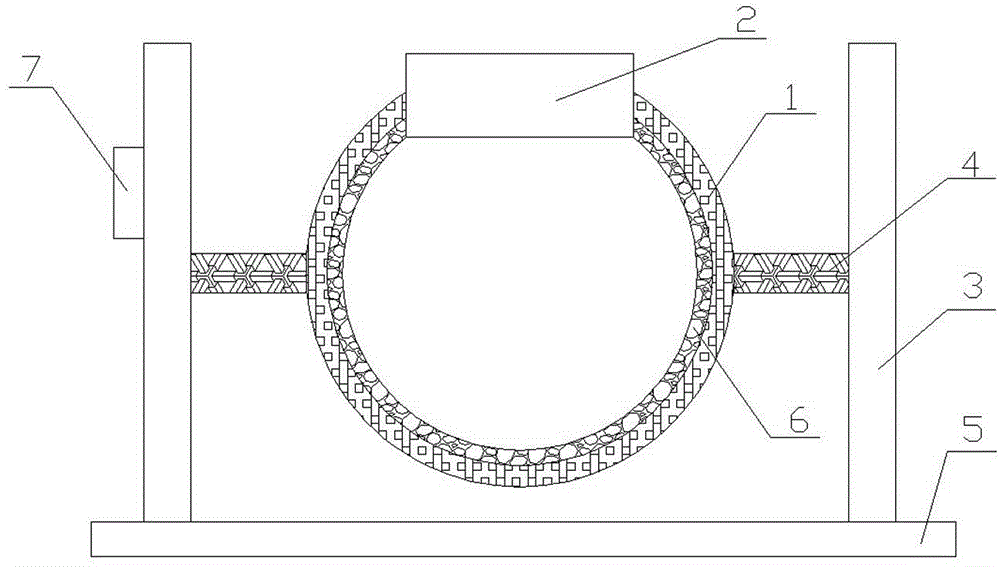

[0013] A spherical graphite purification furnace, comprising a heat preservation shell 1, a top cover 2, a support 3, a rotating shaft 4, and a base 5. It is characterized in that an infrared heating layer 6 is provided on the inner wall of the heat preservation shell 1, and the heat preservation shell 1 and the top cover 2 is a movable connection. The thermal insulation shell 1 and the top cover 2 are fixed by buckles. The thermal insulation shell 1 is spherical. The two ends of the thermal insulation shell 1 are connected to the shaft 4, the outside of the shaft 4 is connected to the bracket 3, and the bottom of the bracket 3 is connected to the base 5.

[0014] A control panel 7 is provided on the support 3 in question.

Embodiment 2

[0016] The rotating shaft 4 can make the spherical graphite purification furnace auto-transmit when it is working, so that the heated area is uniform and the purification accuracy is higher. The control panel 7 can precisely control the speed of the rotating shaft 4 and the temperature of the infrared heating layer 6 of the spherical graphite purification furnace, which improves the precision of graphite purification. After the purification is completed, the tilt angle of the spherical graphite purification furnace can be controlled to facilitate the purification. The graphite is collected or poured out.

Embodiment 3

[0018] The top cover 2 and the spherical graphite purification furnace are sealed with plastic seals. During production, it is not easy to enter other gases, resulting in graphite oxidation at high temperatures. At the same time, the top cover is also made of thermal insulation materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com