A tiltable trailer

A tilting and trailering technology, applied in the field of trailers, can solve the problems of limited length, unfavorable vehicle up and down, and large slope angle, etc., to achieve the effect of controllable tilt angle, convenient operation and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

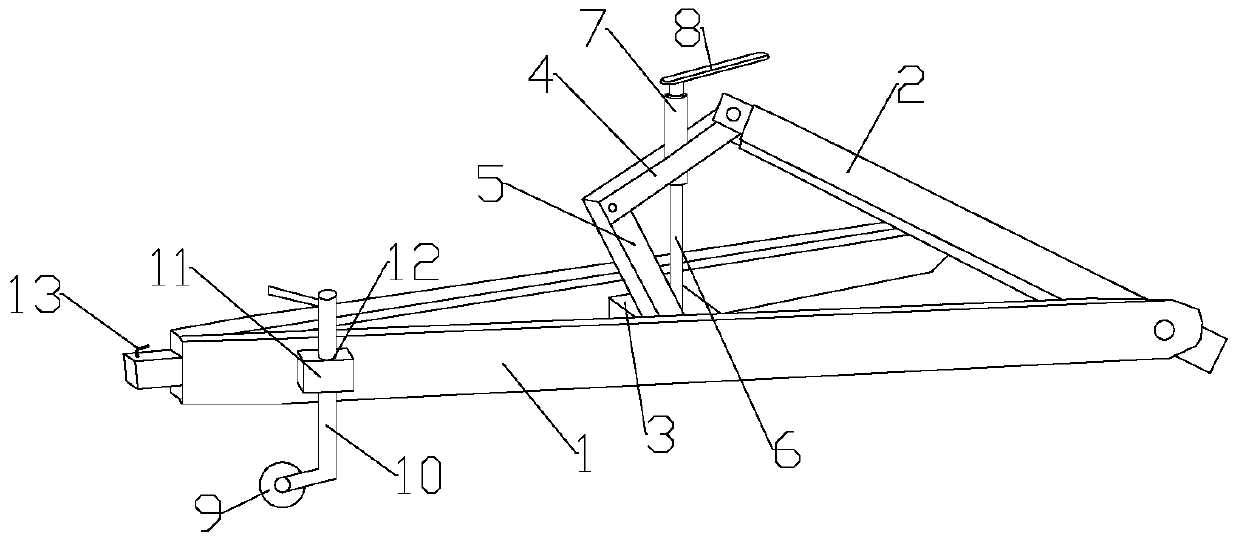

[0015] combine figure 1 with figure 2 As shown, a tiltable trailer of the present invention includes a drag plate 14 and a traction device, and the traction device includes a first traction frame and a second traction frame, and the rear end of the first traction frame is connected to the second traction frame. The rear end of the second traction frame is hinged, and the rear end of the second traction frame is affixed to the front end of the carriage 14. At least one group of running wheels 15 are provided at the bottom of the carriage, wherein the first traction frame is larger than the second traction frame. In this embodiment The first traction frame and the second traction frame are V-shaped structures, and the traction frames can also be arranged in a wedge shape or other shapes, and the open end of the V-shaped structure is the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com