A feeding and clamping device for floor core board groove cutting mechanism

A core board and clamping technology, applied in the direction of slotting machines, conveyors, mortising machines, etc., can solve the problems of inability to realize continuous feeding and clamping, complex structure, etc., and achieve convenient grooving and high automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

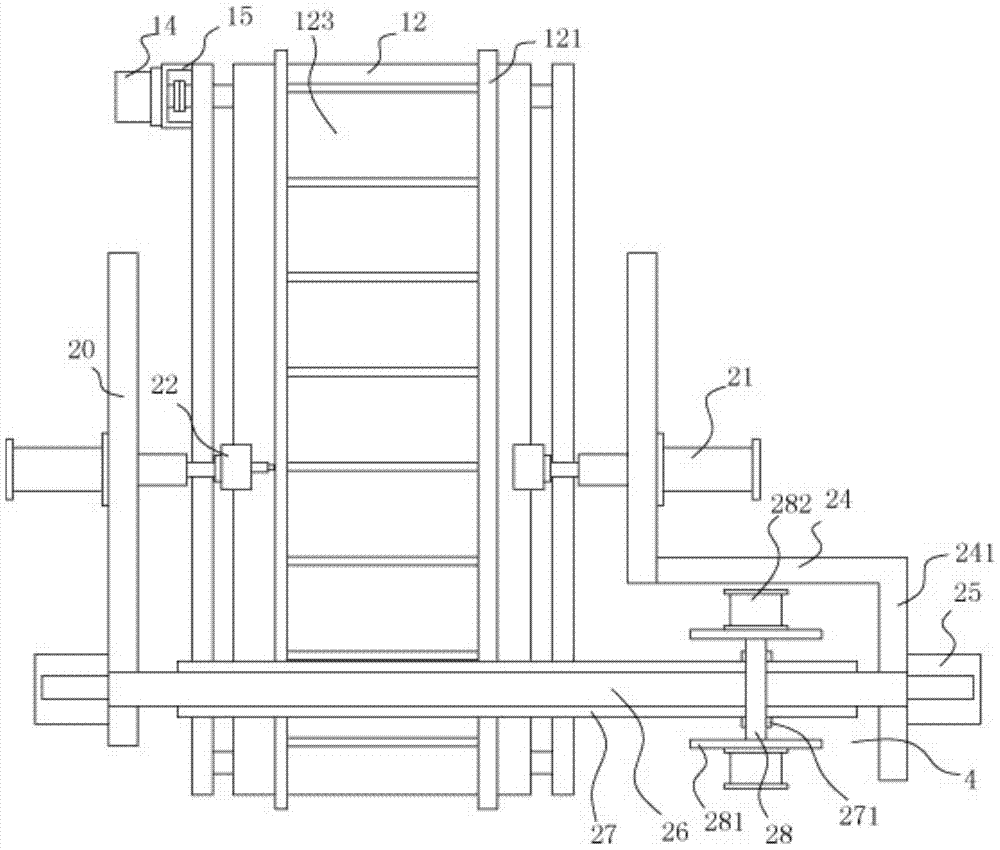

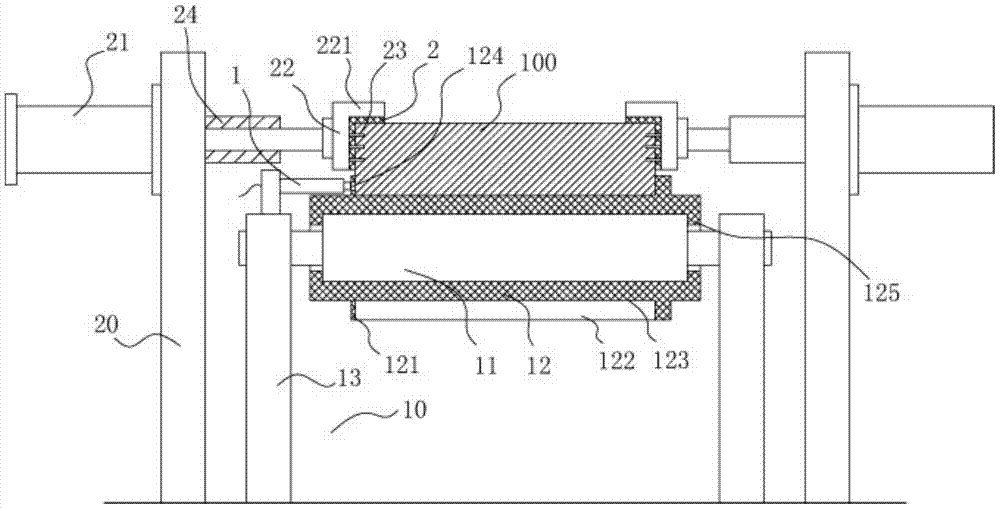

[0021] Example: see Figures 1 to 5 As shown, a material feeding and clamping device for a floor core board grooving mechanism includes a conveying mechanism 10, and the conveying mechanism 10 includes two transmission rollers 11, and a conveying belt 12 is stretched on the two transmission rollers 11, and the two transmission rollers 11 The two ends of the transmission roller 11 are respectively hinged on two support plates 13, the support plates 13 are fixed on the ground, and the driving motor 14 drives one of the transmission rollers 11 to rotate;

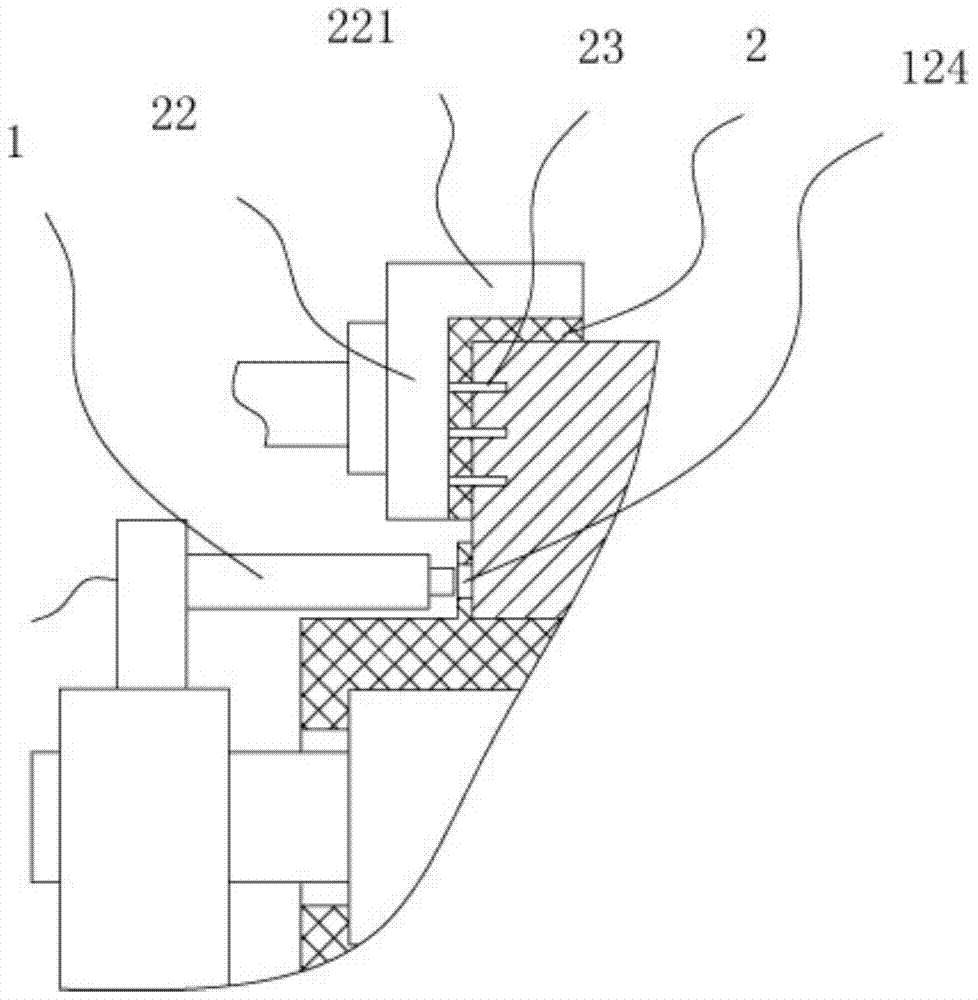

[0022] The ground on both sides of the conveyor belt 12 is fixed with a clamping support plate 20, the clamping support plate 20 is fixed with a clamping cylinder 21, and the push rod of the clamping cylinder 21 passes through the clamping support plate 20 and is positioned at the side of the conveyor belt 12. Above both sides, clamping blocks 22 are fixed at the end of the push rod clamping the cylinder 21, and a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com