Progressive die stamping device and process for porous plate of automobile air-conditioning parallel flow evaporator

A technology of automotive air conditioners and stamping devices, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high scrap rate and low efficiency of stamping, affecting the production efficiency and production cost of enterprises, and achieves low maintenance costs, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

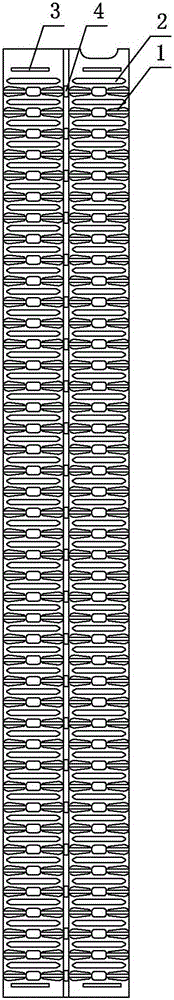

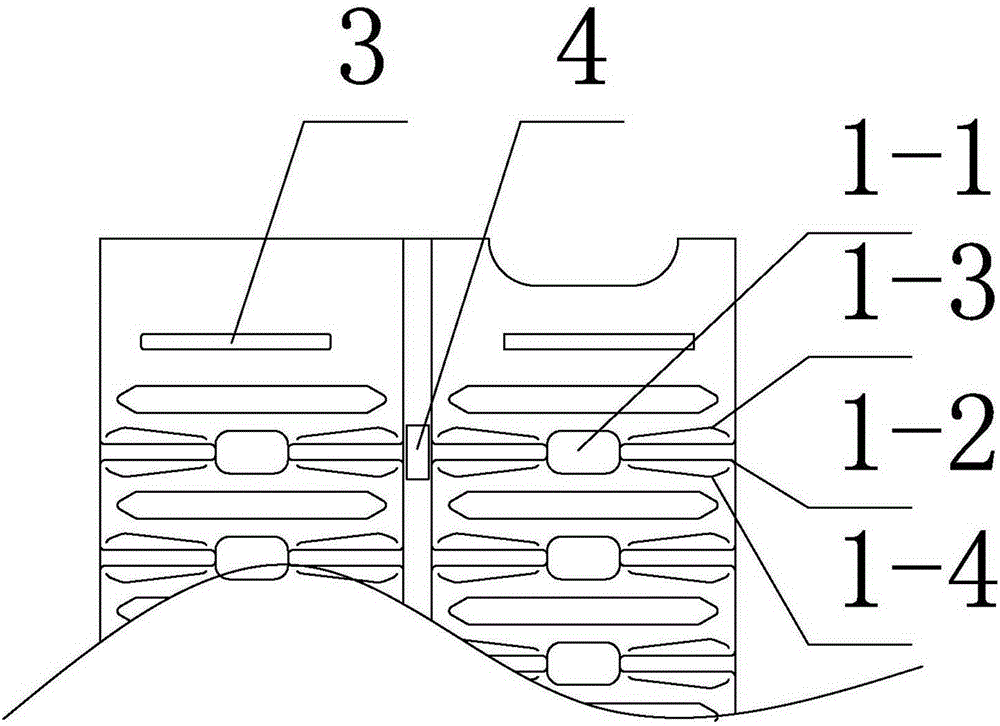

[0034] The invention provides a porous plate for a parallel flow evaporator of an automobile air conditioner. The porous plate includes reinforcing ribs 1 and flat tube grooves 2 arranged in parallel, and the reinforcing ribs 1 and flat tube grooves 2 are arrayed on the porous plate in a manner of 2 rows and N columns. , and N is greater than or equal to 1; two strip grooves 3 are provided at both ends of the perforated plate; a plurality of rectangular slots 4 are also provided between two rows of reinforcing ribs of the perforated plate; the reinforcing rib is composed of multiple reinforcing rib lines Bow-knot shape, the reinforcing rib lines include arc-shaped circle lines 1-1, U-shaped lines 1-2 are arranged on both sides of the arc-shaped circle lines, and upper arc-shaped lines 1-3 and lower arc-shaped lines are also arranged on both sides of the U-shaped lines Lines 1-4.

Embodiment 2

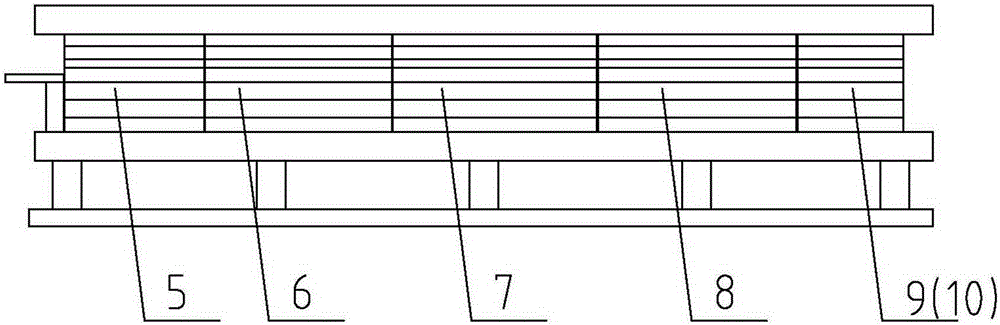

[0036] The present invention also provides a progressive die stamping device for the perforated plate of the parallel-flow evaporator of an automobile air conditioner, including a punch press that drives the progressive die stamping device. The progressive die stamping device is provided with first to fifth stations, and the material belt passes After the first to the fifth station, the finished product of the perforated plate is made;

[0037] The first station is provided with the 1# mold 5 for punching and puncturing; comprises 1# mold upper mold 5-1 and 1# mold lower mold 5-2.

[0038] The second station is provided with 2# mold 6 for pre-bending, beading and trimming; it includes 2# mold upper mold 6-1 and 2# mold lower mold 6-2.

[0039] The 3rd station is provided with the 3# mold 7 that is used for pre-bending, embossing or trimming on it; Comprising 3# mold upper mold 7-1 and 3# mold lower mold 7-2.

[0040] The 4th station is provided with the 4# mold 8 that is used...

Embodiment 3

[0051] The present invention also provides a stamping process of the porous plate of the parallel flow evaporator of the automobile air conditioner. The stamping process of the porous plate uses a progressive die stamping device, including the following steps,

[0052] (1) At the first station, the punching, puncturing and punching processes are carried out on both sides of the strip.

[0053] (2) At the second station, the preliminary prototype of the perforated plate is completed and displayed from the material belt through the pre-bending stamping, forming stamping, and punching of reinforcing ribs in sequence.

[0054] (3) In the third station, edge trimming is carried out, and the connecting part between the connected perforated plates is removed, and forming and shaping are carried out.

[0055] (4) At the fourth station, punch strip grooves 3 at both ends of the perforated plate and rectangular slots 4 on the central axis of the perforated plate, and then punch out flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com