A cleaning method after precision polishing of optical components

A technology of optical components and precision polishing, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., to achieve the effects of avoiding ablation damage, high cleanliness, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

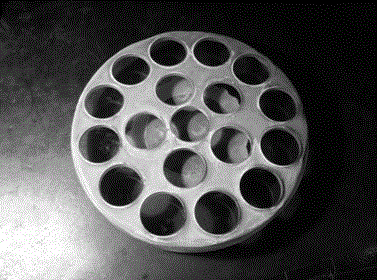

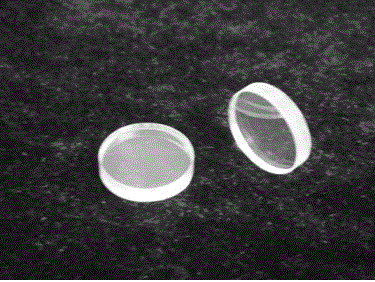

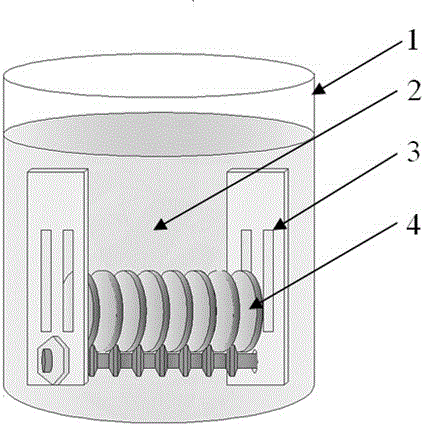

[0033] Fused silica planar optics processed by platter, cleaned after long time precision polishing.

[0034] 1. Cleaning steps:

[0035] (1) The JGS1 fused silica optical element with a diameter of 25mm and a thickness of 6mm is glued on a quartz optical glue board with a diameter of 190mm and a thickness of 25mm by optical glue method. Gas and fall off the light glue board. Afterwards, classical polishing is carried out, the parabolic powder is ceria parabolic powder, and the polishing cycle is 200 hours. After the optical components are removed from the optical plastic sheet by freezing method, put them into gasoline for immersion. The gasoline is aviation gasoline with less impurities. The immersion time is 40 minutes, and the immersion temperature is room temperature 25°C;

[0036] (2) Place the component in carbon tetrachloride solution and soak for 2.5 hours at a room temperature of 25°C to further remove the polishing powder particles attached to the surface of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com