High-heeled shoe last base plate and insole simulation design method and simulated insole

A simulation design, high-heeled shoe technology, applied in shoe lasts, soles, footwear and other directions, can solve the problems of not taking into account the landing state of the soles of the feet, difficult to fit high-heeled shoes, physical health injuries, etc., to protect the forefoot arch, fast assembly, The effect of reducing the big foot bone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: Example of simulation design method for high-heeled shoe last base plate designed with national standard No. 230 female high-heeled shoes

[0061] Specific steps are as follows:

[0062] 1. According to the design of the existing national standard last, the traditional standard midsole is made, and the heel of the standard midsole is raised to the same height as the back sill of the last, and fixed in a square box. The box is slightly longer and wider than human feet. , the height of the heel of the standard midsole is the actual heel height of the national standard last. (in the present embodiment, the super long women's high-heeled shoes with shallow mouth and pointed head of 70mm back stilt height are design models).

[0063] The main design data of the national standard 70mm rear sill shoe last are as follows:

[0064] Metatarsal circumference 217mm; tarsal circumference 208mm; basic width 73.1mm; inner width of the thumb 27.7mm; outer width of the l...

Embodiment 2

[0074] Embodiment 2: This embodiment provides an example of a midsole simulation design method based on the shoe last soleplate simulation model obtained in Embodiment 1

[0075] Specific steps are as follows:

[0076] 1. According to the simulation model of the shoe last bottom plate obtained in embodiment 1, design the basic shape of the upper surface of the midsole 3D model matching it. The radian and width data of the upper surface of the 3D model of the midsole are consistent with the simulation model of the shoe last, and the upper surface of the 3D model of the midsole is a concave surface that coincides with the bottom surface of the simulation model of the shoe last.

[0077] 2. Since the simulation model of the shoe last base plate of the simulation design is a free-form surface like a foot, the heel surface of the heel is high inside and low outside. The difference in internal and external heights will cause the heel to be unable to be perpendicular to the ground a...

Embodiment 3

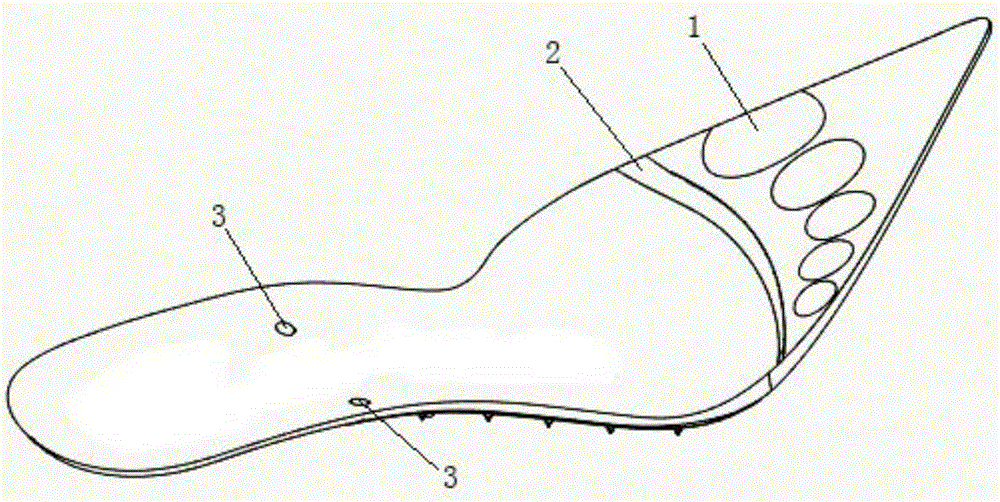

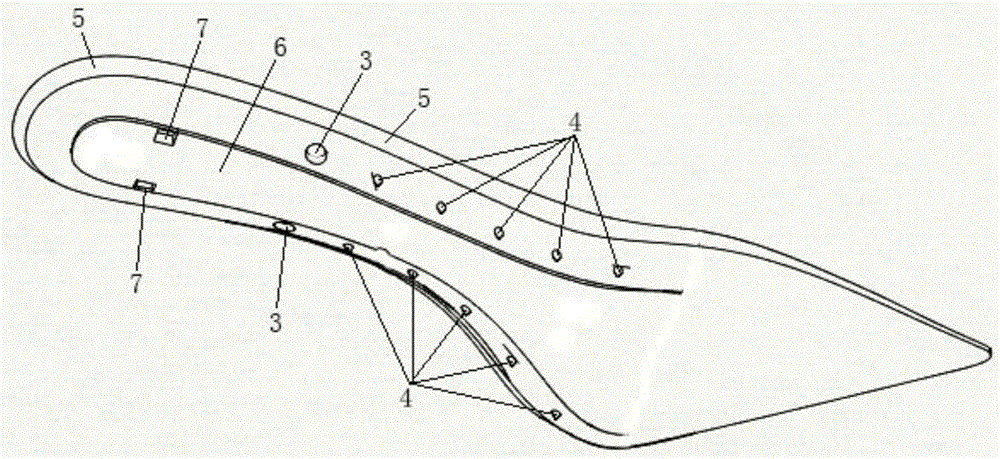

[0082] Embodiment 3: the midsole simulation model prepared by the midsole simulation design method of embodiment 2

[0083] As shown in the drawings, the lower bottom surfaces on both sides of the midsole simulation model of Embodiment 3 are respectively provided with five conical spikes. And the upper surface of the forefoot is provided with 5 toe sockets corresponding to the toes of the human body. And between its forefoot sole and the middle part of the midsole simulation model, a transverse anti-slip convex strip is arranged. And there are more than two ferrule-type positioning holes at the sole of the foot.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com