Heat sink for variable frequency motor

A heat dissipation device and variable frequency motor technology, which is applied in the direction of electromechanical devices, cooling/ventilation devices, electrical components, etc., and can solve problems such as motor shaft wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

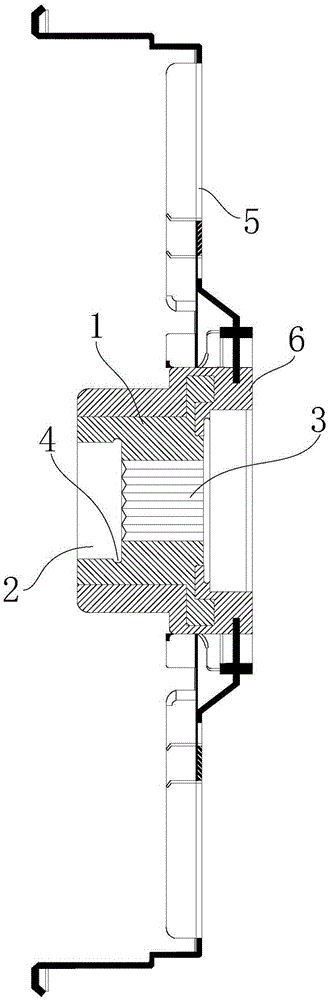

[0013] Example: heat dissipation device for variable frequency motor

[0014] See attached figure 1 And attached figure 2 As shown, the heat dissipation device for the frequency conversion motor includes a heat dissipation impeller 5, the center of the heat dissipation impeller 5 is fixed with a disc-shaped base 6, and an intermediate gear 1 is fixed on the disc-shaped base 6; the intermediate gear 1 There is a through hole in the center of the center, the through hole is divided into two sections, one section is the motor shaft accommodating section 2, and the other section is the inner spline section 3; the diameter of the motor shaft accommodating section 2 is larger than the inner spline section 3, The junction of the two constitutes a stepped portion, and the motor shaft accommodating section 2 is provided with a groove 4 at the junction with the inner spline section 3 . Since the groove 4 is provided at the junction of the motor shaft accommodating section and the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com