High-specific capacity lithium-sulfur secondary battery composite cathode and preparation method thereof

A lithium-sulfur secondary battery and composite cathode technology, applied in the field of electrochemical batteries, can solve the problems of poor cycle performance and high carbon content, and achieve the effects of high electrical conductivity, high sulfur content and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the lithium-sulfur secondary battery composite positive electrode of the present invention comprises the following steps:

[0026] a) Place the elemental sulfur powder, copper powder and conductive carbon black required for electrode preparation in a vacuum oven to dry and set aside. The conductive carbon black used includes acetylene black, activated carbon, ordered or disordered mesoporous carbon, carbon nanotubes, conductive carbon fiber (VGCF), carbon aerogel, graphene, conductive graphite KS6 or Super-P. Elemental sulfur includes sublimated sulfur, crystalline sulfur, amorphous sulfur, colloidal sulfur and other forms of elemental sulfur. Copper powder particles are required to be micron or nano-sized;

[0027] b) According to the mass ratio of sublimated sulfur: copper powder: conductive agent (one or several kinds of conductive agent in step a): binder=65~85:20~1:5~6:10~8 Preparation of sulfur cathode. The binder used is polyvinyliden...

Embodiment 1

[0032] (1) Weigh the sublimed sulfur according to the mass ratio: Cu:SP:LA132=70:15:5:10, and add four times the solid mass of deionized water (that is, the solid-liquid ratio is 25%) to prepare a high-sulfur content positive pole piece;

[0033] (2) Place the prepared positive electrode piece in a vacuum oven at 80°C for 72h;

[0034] (3) The positive electrode sheet was detected and analyzed by thermogravimetry and elemental analyzer, and the elemental sulfur content in the final sulfur positive electrode was as high as about 63%. It can be seen from the calculation that the copper powder in the electrode is basically completely converted into copper sulfide.

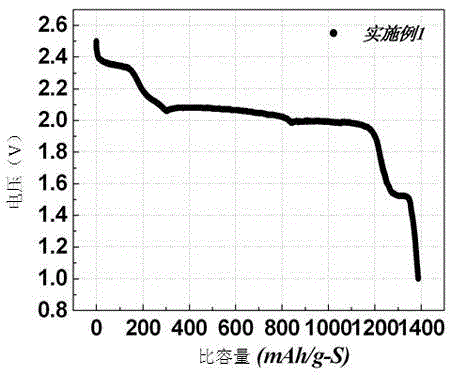

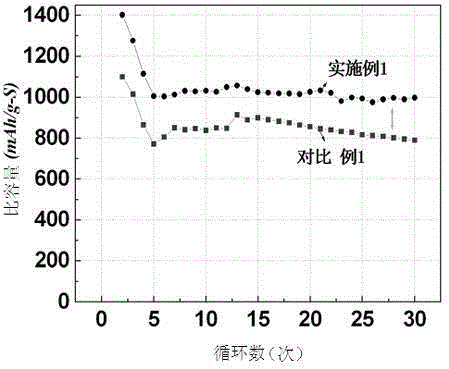

[0035] The obtained electrode pole piece and lithium sheet were assembled into a 2032-type button battery for testing. The discharge curve at room temperature is as figure 1 As shown, the first discharge capacity can be as high as 1400mAh / g-S (milliampere hour / gram-sulfur). It can be seen from the discharge curves ...

Embodiment 2

[0037] (1) Weigh the sublimated sulfur according to the mass ratio: Cu:SP:LA132=70:15:5:10, and add deionized water four times the solid mass (that is, the solid-liquid ratio is 25%) to prepare a high-sulfur content positive pole piece;

[0038] (2) Place the prepared positive pole piece in a vacuum oven at 80°C for 24h;

[0039] (3) The positive electrode was detected and analyzed by thermogravimetry and elemental analyzer. The elemental sulfur content in the final sulfur positive electrode was as high as about 65%, indicating that the copper powder in the electrode was not completely converted into copper sulfide, and there were nearly 5wt% highly conductive particles in the electrode. copper powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com