A method and device for detecting defects of pipe elbows based on far-field eddy currents

A pipeline elbow, far-field eddy current technology, applied in the direction of material magnetic variables, can solve pipeline elbow defects, pipeline elbow detection and other problems, achieve the same sensitivity, easy defect identification, and reduce detection blind spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

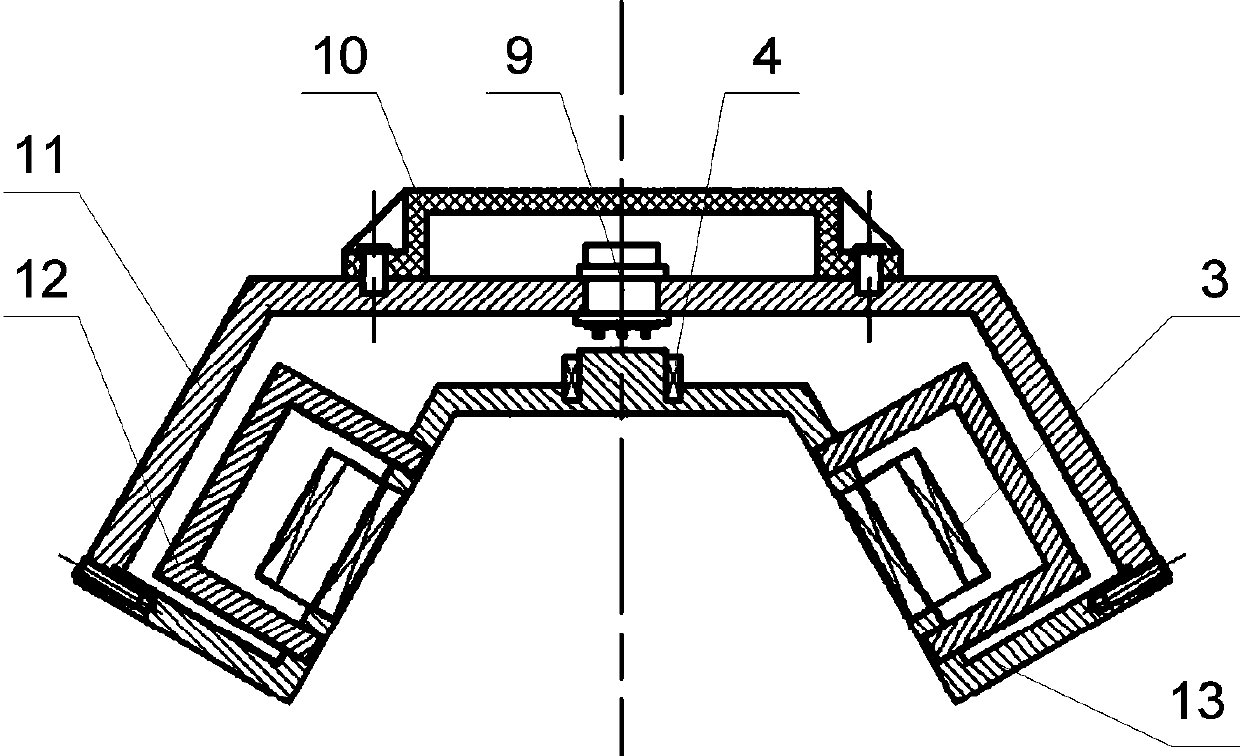

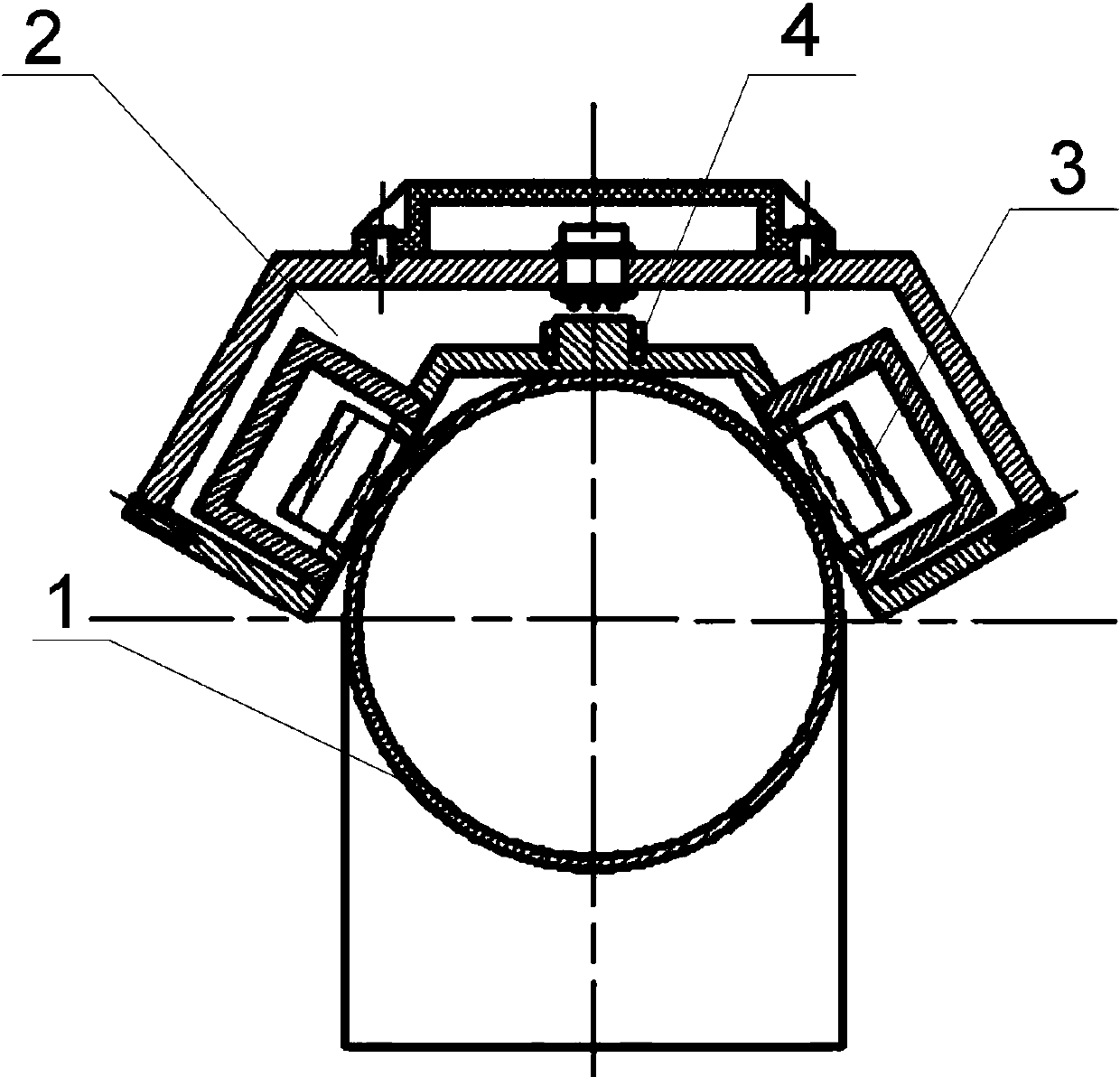

[0034] Embodiment 1, refer to Figure 1-3 , The shielding unit 12 is made of silicon steel sheet. The handle 10 is connected to the end cover 11 by a hexagonal screw, and the end cover 11 is connected to the housing 13 by a cross recessed pan head screw. The excitation coil 3 is fixed at both ends of the bottom of the casing, the receiving coil 4 is fixed at the center of the bottom of the casing cavity, the shielding unit 12 is covered above the excitation coil 3 , and the leads of the excitation coil 3 and the receiving coil 4 are connected to the aviation socket 9 . The far-field eddy current sensor is arranged on the cross section of the pipeline elbow 1; the excitation unit includes an excitation coil 3, and the receiving unit includes a receiving coil 4, the axis of the excitation coil 3 is arranged along the circumference of the pipeline elbow 1, and the axis of the receiving coil 4 It is arranged radially along the pipe elbow; the receiving coil 4 is located in the fa...

Embodiment 2

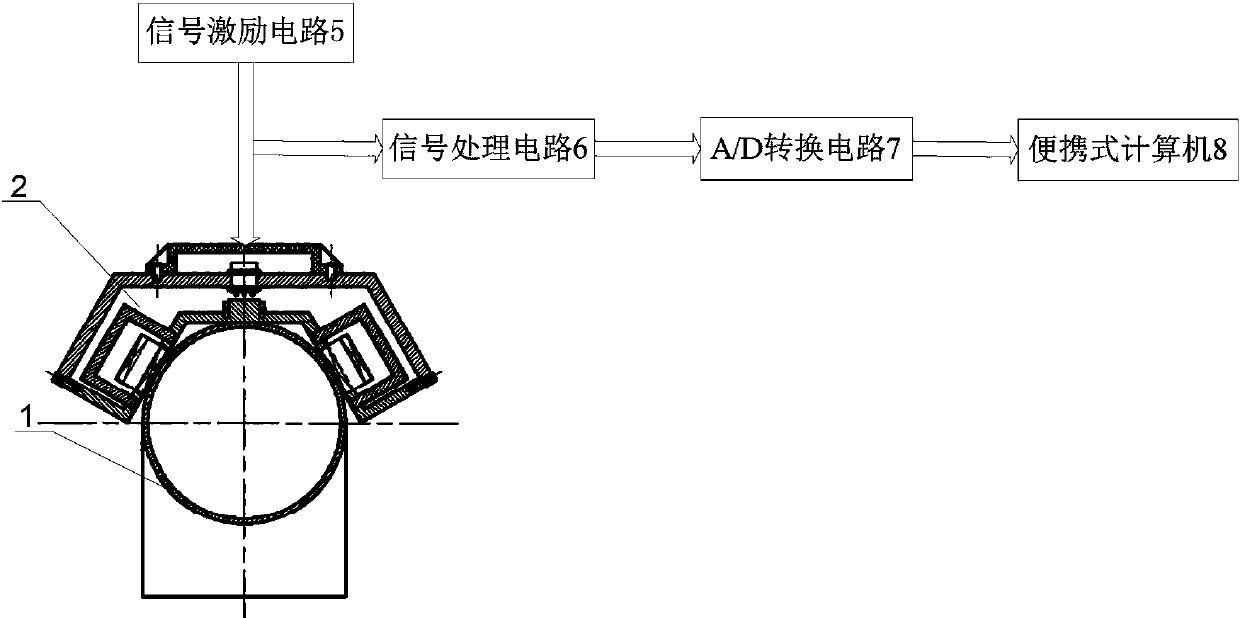

[0037] Example 2, see image 3 , the far-field eddy current sensor of the present invention is connected with the harmonic signal excitation circuit, signal processing circuit, A / D conversion circuit and computer successively, and the harmonic signal excitation circuit provides harmonic excitation to the far-field eddy current sensor, and the far-field eddy current sensor is set On the outer surface of the pipe elbow, the eddy current is induced by excitation and the indirect coupling magnetic field signal in the far field area of the eddy current is received, converted into a voltage signal, and then sent to the signal processing circuit. The signal processing circuit amplifies, filters, and After comparison, it is sent to the A / D conversion circuit. The A / D conversion circuit converts the analog signal into a digital signal and sends it to the computer. The computer processes the received data to obtain the corrosion and crack defect information of the pipe elbow under test...

Embodiment 3

[0038] Embodiment 3, refer to Figure 1 to Figure 5 , the pipe elbow detection device of the present invention consists of a far-field eddy current sensor 2 composed of two identical excitation units and a receiving unit, and the two excitation units are respectively located on both sides of the receiving unit. The excitation unit includes an excitation coil 3, the receiving unit includes a receiving coil 4, the axis of the excitation coil 3 is arranged along the circumference of the pipe elbow 1, the axis of the receiving coil 4 is arranged radially along the pipe elbow, and the receiving coil 4 is located in the measuring indirect The far-field region where magnetic field signals are coupled. The far-field eddy current sensor 2 includes a housing 13, an end cover 11, an excitation coil 3, a receiving coil 4 and a socket, and the socket can adopt the structural form of an aviation socket 9, or other structural forms; the housing 13 is provided with an internal The "︹" type s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com