Bottleneck defect detecting method and detecting device

A detection method and detection device technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of loss of consumers' vital interests, influence on the reputation of manufacturers, injuries to consumers, etc., to improve detection accuracy, fast detection speed, and expand Effect of detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

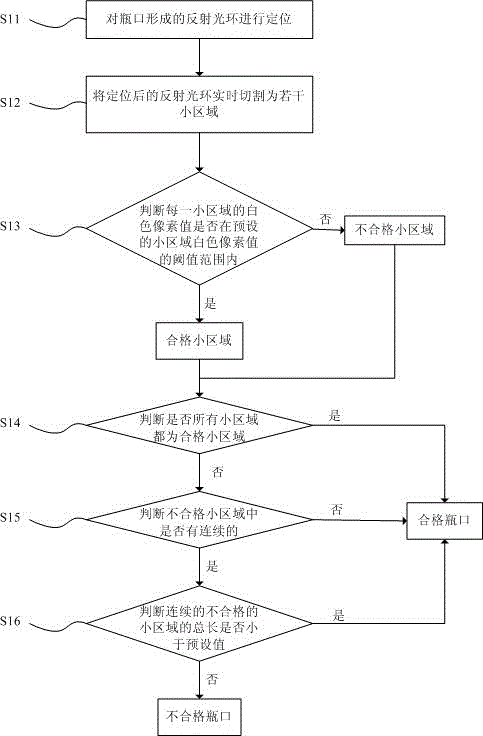

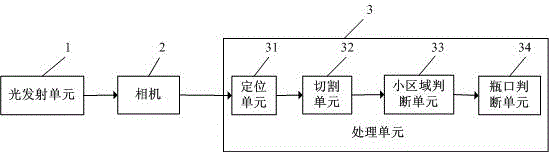

[0046] combine figure 2 , the present embodiment describes in detail the detection method of the bottle mouth defect of the present invention, which includes the following steps:

[0047] S11: Positioning the reflection halo formed by the bottle mouth;

[0048] S12: Cutting the positioned reflective halo into several small areas in real time;

[0049] S13: judging whether the white pixel value of each small area is within the preset threshold range of the white pixel value of the small area, if so, judging the small area as a qualified small area, otherwise judging as an unqualified small area;

[0050] S14: Judging whether all the small areas are qualified small areas, if yes, judging as a qualified bottle mouth, otherwise judging as an unqualified bottle mouth.

[0051] The specific operation method is: divide the reflection halo into 255 equal parts, and judge whether the white pixel value of each small area is within the preset threshold range of the white pixel value o...

Embodiment 2

[0058] This embodiment adds the step of light compensation on the basis of Embodiment 1, specifically: after dividing the reflective halo into several small areas, adding all the white pixels of the reflective halo to obtain a sum of white pixels value, and then compare it with the preset minimum value. If it is smaller than the preset minimum value, the reflected light is weak, and the light of the reflected halo is compensated at this time; if it is greater than the preset minimum value, the light reflected Bright and clear, no more compensation.

Embodiment 3

[0060] There is also a problem in practical applications, that is, the reflection halo of some bottle mouths is particularly thick, which causes the white pixel value in the small area to be cut to easily exceed the preset upper limit of the white pixel value in the small area. will be considered as a problematic bottle mouth, in order to solve this problem, the threshold range of white pixel values in small areas needs to be reset. First, calculate the average value of the white pixel values of all small areas, re-determine the threshold range of the white pixel values of the new small area according to this average value, and then judge whether each small area is one by one according to the threshold value range of the white pixel values of the new small area. It is a qualified small area. If the white pixel value of the small area is within the threshold range of the white pixel value of the new small area, it is a qualified small area, otherwise it is an unqualified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com