Check bolt

A technology of anti-loosening bolts and fastening bolts, which is applied in the direction of bolts, screws, nuts, etc., and can solve problems such as vibration, difficulty in fastening, and large amount of coal passing through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

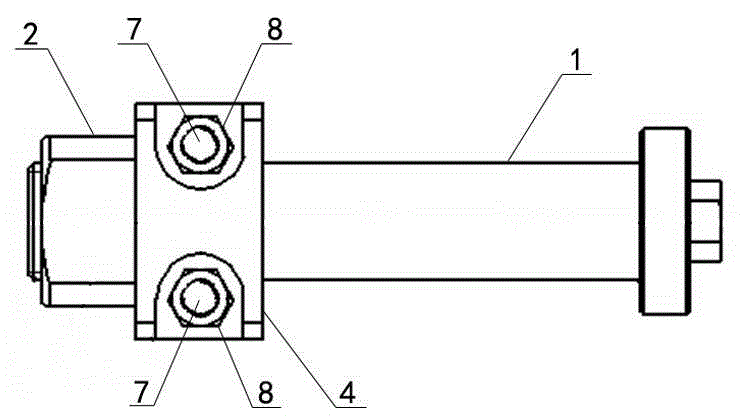

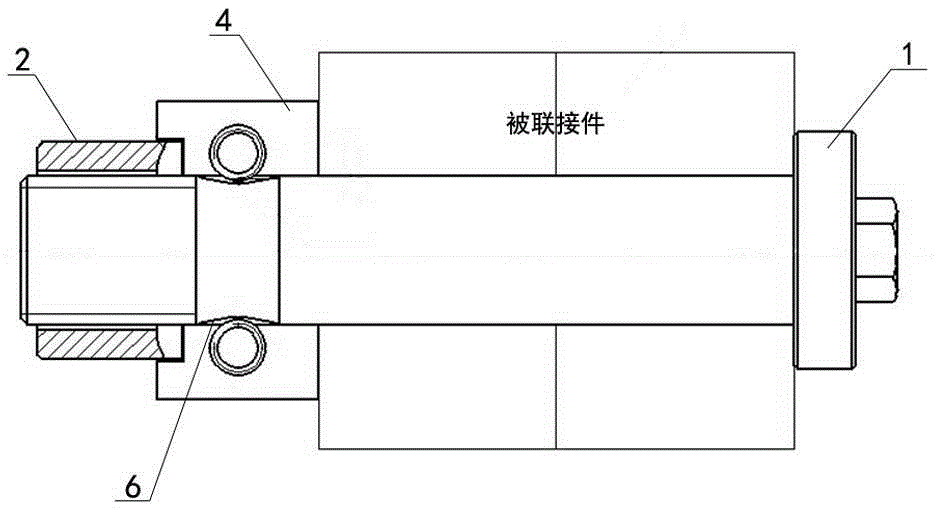

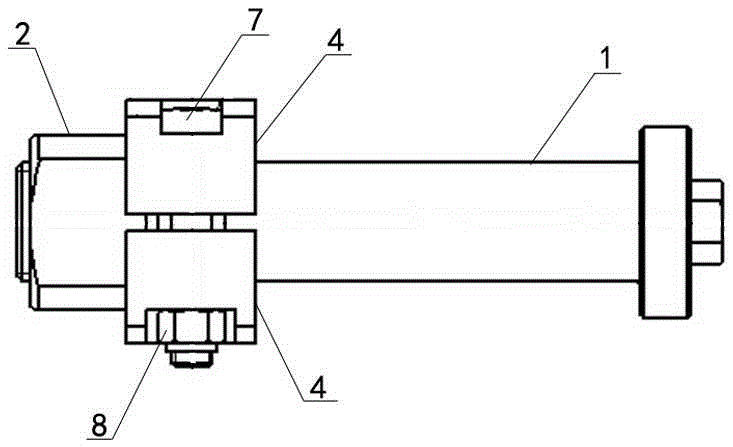

[0020] An anti-loosening bolt, including a fastening bolt 1 and a fastening nut 2 threadedly engaged with the fastening bolt 1, and also includes two semicircular blocks 4 fastened on the screw rod of the fastening bolt 1, two semicircular The ends of the ring block 4 are locked on the screw rod of the fastening bolt 1 through the locking bolt 7 and the locking nut 8; one end of the fastening nut 2 is obliquely cut with a convex self-locking surface 3 up and down, two The same end of the semi-circular block 4 is chamfered inwardly with a concave self-locking surface 5 which is fastened with the convex self-locking surface 3 .

[0021] During specific implementation, the tightening bolt 1 screw rod opposite to the locking bolt 7 screw rod is provided with an annular anti-retreat groove 6 along the circumference, and the locking bolt 7 screw rod is only located in the anti-retreat groove 6 . When the locking bolt 7 and the locking nut 8 become loose during use, the screw rod of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com