6XXX aluminum alloy and machining method thereof

A processing method and technology of aluminum alloy, applied in the field of high-strength aluminum alloy for exterior parts of electronic products and its processing, 6XXX series aluminum alloy field, to achieve the effect of good anodizing performance, high strength and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

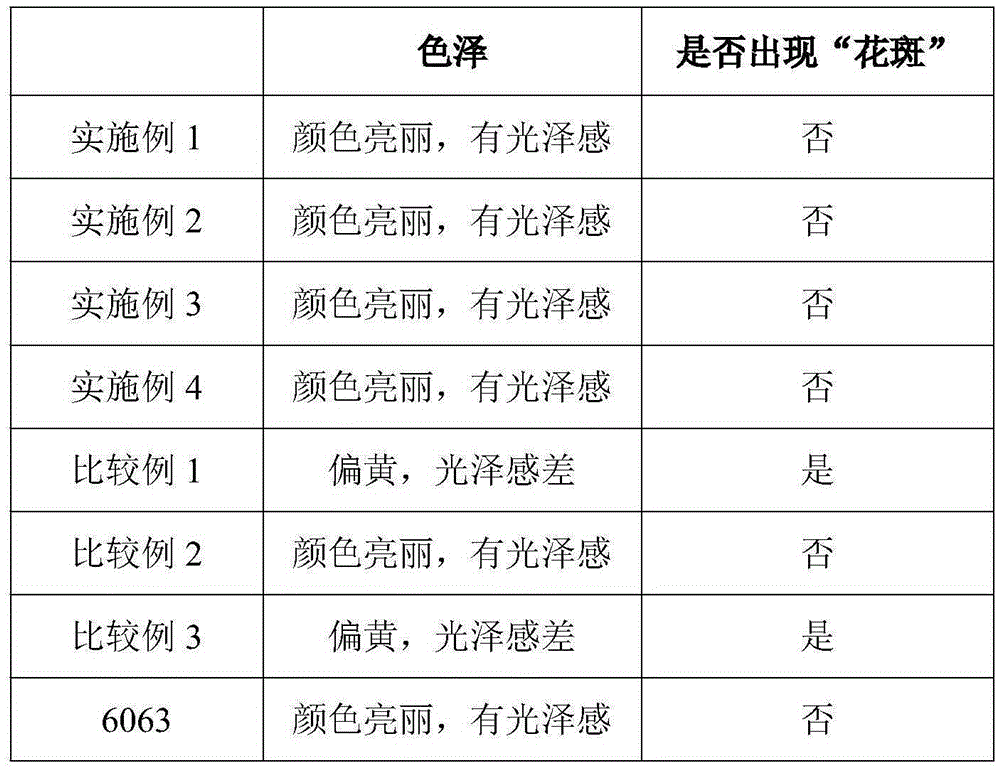

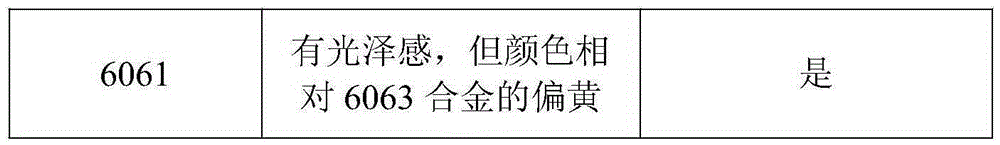

Examples

Embodiment 1

[0032] Semi-continuous cast rod: diameter 178mm, cast rod composition in terms of mass percentage: Mg: 1.12wt%, Si: 1.05wt%, Cu: 0.95wt%, Mn: 0.01wt%, Cr: 0.01wt%, Fe: 0.13 wt%, Zn: 0.1wt%, Ti: 0.04wt%, Zr: 0.002wt%, and the balance is Al.

[0033] Homogenization heat treatment for alloy cast rods: from room temperature to 530°C at a rate of 90°C / h, and keep it for 15 hours, then raise it to 550°C at a rate of 50°C / h, keep it for 20 hours, and then heat it at 160°C / h Fast cool down. The material is extruded (the heating temperature of the extrusion ingot is 520°C, the temperature of the extrusion cylinder is 470°C, the temperature of the mold is 500°C, the speed of the extrusion rod is 2.8mm / s, and the outlet temperature of the extruded material is 540°C), on-line After quenching and straightening, carry out artificial aging (175℃×8h).

Embodiment 2

[0035] Semi-continuous cast rod: diameter 178mm, cast rod composition in terms of mass percentage: Mg: 0.97wt%, Si: 1.03wt%, Cu: 0.88wt%, Mn: 0.005wt%, Cr: 0.005wt%, Fe: 0.12 wt%, Zn: 0.02wt%, Ti: 0.02wt%, Zr: 0.005wt%, and the balance is Al.

[0036] Homogenizing heat treatment for alloy cast rods: from room temperature to 535°C at a rate of 80°C / h, and keep it for 12 hours, then raise it to 550°C at a rate of 15°C / h, keep it for 20 hours, and then heat it at 160°C / h Fast cool down. The material is extruded (the heating temperature of the extrusion ingot is 530°C, the temperature of the extrusion cylinder is 460°C, the temperature of the mold is 490°C, the speed of the extrusion rod is 3mm / s, and the outlet temperature of the extruded material is 545°C), quenched online , Artificial aging after straightening (175℃×8h).

Embodiment 3

[0038]Semi-continuous cast rod: diameter 178mm, cast rod composition in terms of mass percentage: Mg: 0.96wt%, Si: 0.95wt%, Cu: 0.65wt%, Mn: 0.05wt%, Cr: 0.03wt%, Fe: 0.16 wt%, Zn: 0.11wt%, Ti: 0.03wt%, Zr: 0.003wt%, and the balance is Al.

[0039] Homogenization heat treatment for alloy cast rods: from room temperature to 535°C at a rate of 75°C / h, and keep it for 12 hours, then raise it to 550°C at a rate of 10°C / h, keep it for 22 hours, and then heat it at 160°C / h Fast cool down. Extrude the material (the heating temperature of the extrusion ingot is 520°C, the temperature of the extrusion barrel is 460°C, the temperature of the mold is 490°C, the speed of the extrusion rod is 3mm / s, and the outlet temperature of the extruded material is 550°C), online quenching , Artificial aging after straightening (175℃×8h).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com