In-situ reinforcement preparation method and device for high-strength and high-ductility casting magnesium-based composite material

A composite material and in-situ strengthening technology, applied in the field of magnesium alloy materials, can solve the problems of high preparation cost, difficult to control the reaction process, pollution, etc., and achieve the effects of high preparation efficiency, increased energy consumption, and no pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

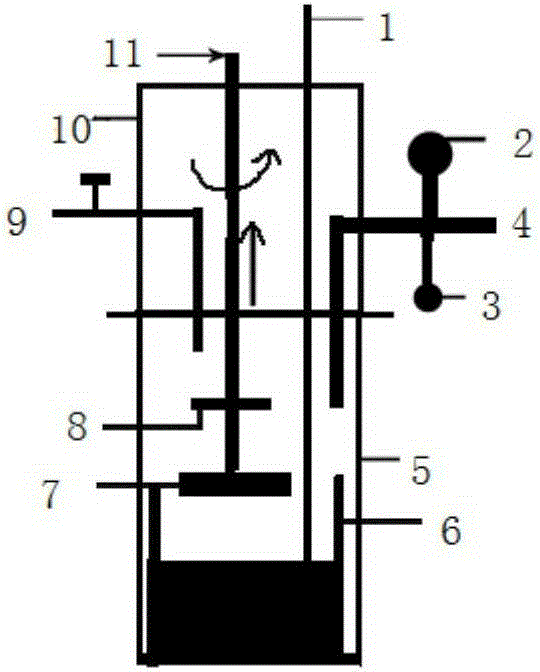

[0024] The technical solution of the present invention is based on the basic principle of in-situ generation of strengthening particles in the magnesium alloy melt, but if the reaction gas nitrogen is simply introduced into the magnesium alloy melt, the strengthening phase cannot be formed in the magnesium alloy melt ALN, but only a thin layer of ALN can be formed on the surface of the melt. Due to the passivation of ALN, it is difficult to form ALN inside the alloy melt. This is also the core of the inability of this technology to continue to develop at home and abroad. Aiming at this principle, the present invention designs the preparation device ingeniously: firstly, a heat preservation chamber is installed on the upper part of the vacuum chamber, which effectively solves the problems of air leakage and air entry caused by the up and down movement of the gas tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com