Suspension damping electric wheel

A technology of electric wheels and suspensions, applied in the direction of suspensions, elastic suspensions, motion deposition, etc., which can solve the problems of complex structure, troublesome installation and disassembly, and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

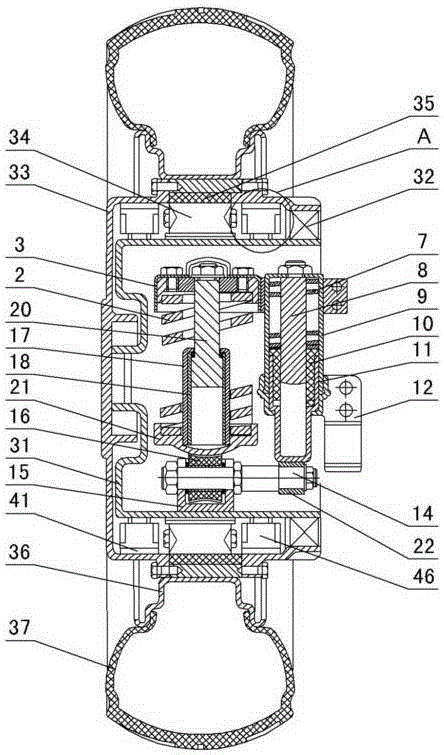

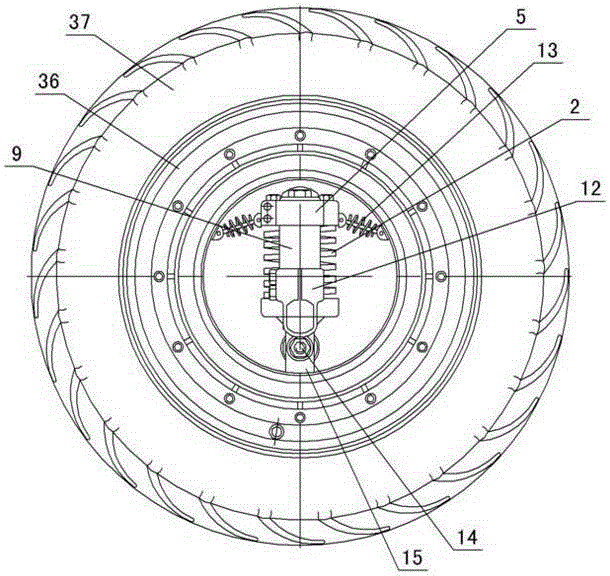

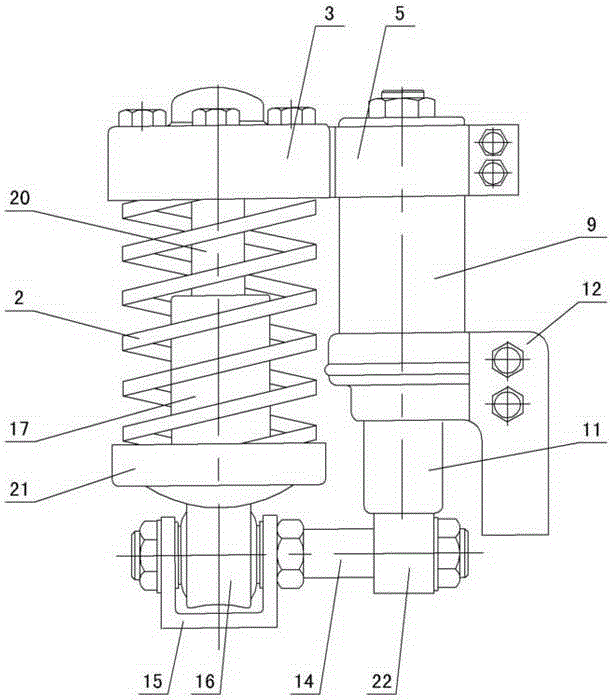

[0013] The invention relates to a suspension shock-absorbing electric wheel, such as figure 1 — Figure 6As shown, it is characterized in that: it includes an inner steel ring 31, an inner bearing 32, an electromagnetic brake, a bearing gland 33, a hub motor stator 34, a hub motor rotor 35, a tire steel ring 36 and a tire 37 are arranged in sequence outside the inner steel ring, and the inner A suspension shock absorber is set in the steel ring, and the suspension shock absorber includes a shock absorber assembly and a suspension assembly. The shock absorber assembly includes a housing 9, and the outside of the housing is installed on the electric vehicle chassis connecting seat 12. On the car, a guide post lubricating sleeve 10, a guide sleeve 11 and a damping spring 7 are arranged in the housing, and a guide post 8 is arranged in the guide post lubricating sleeve, the guide sleeve and the damping spring. The suspension assembly includes an upper end cover 3 and a lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com