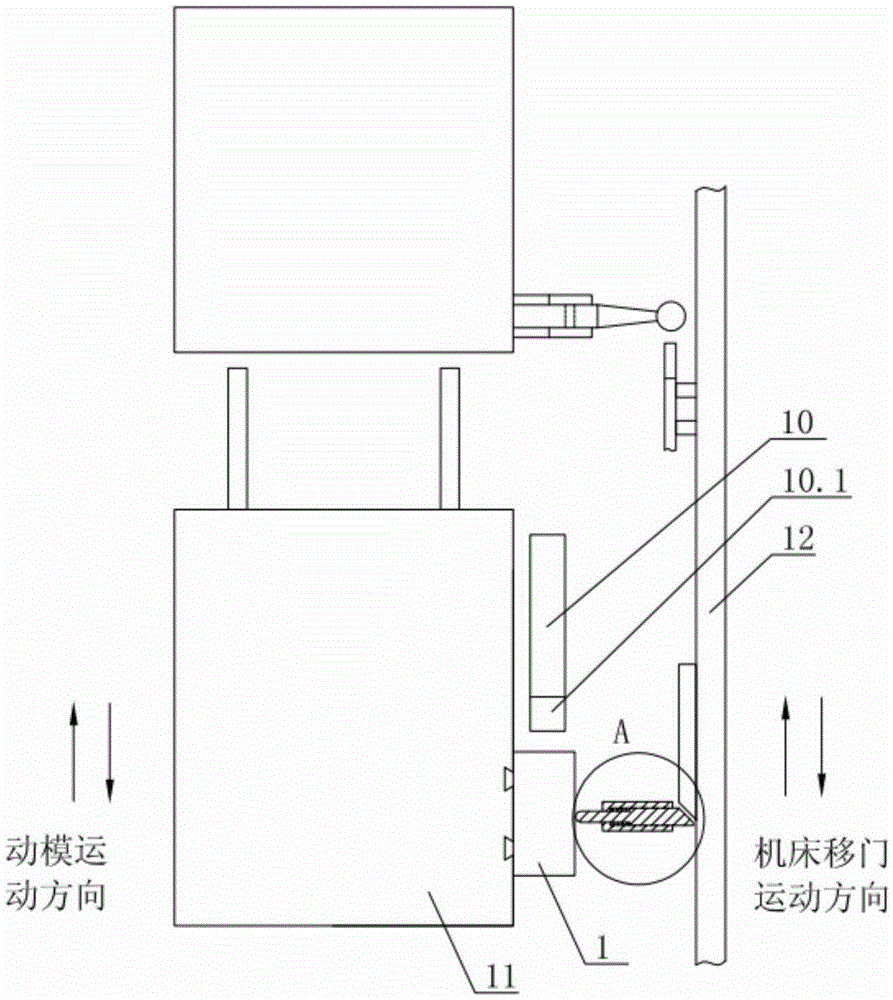

Protection mechanism of horizontal injection molding machine

A technology for an injection molding machine and a protection mechanism, which is applied to the protection mechanism field of a horizontal injection molding machine, can solve the problems of residual material stuck in the sprue on the mold, damage to the mold, low degree of automation, etc., and achieves the effect of not being damaged easily.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

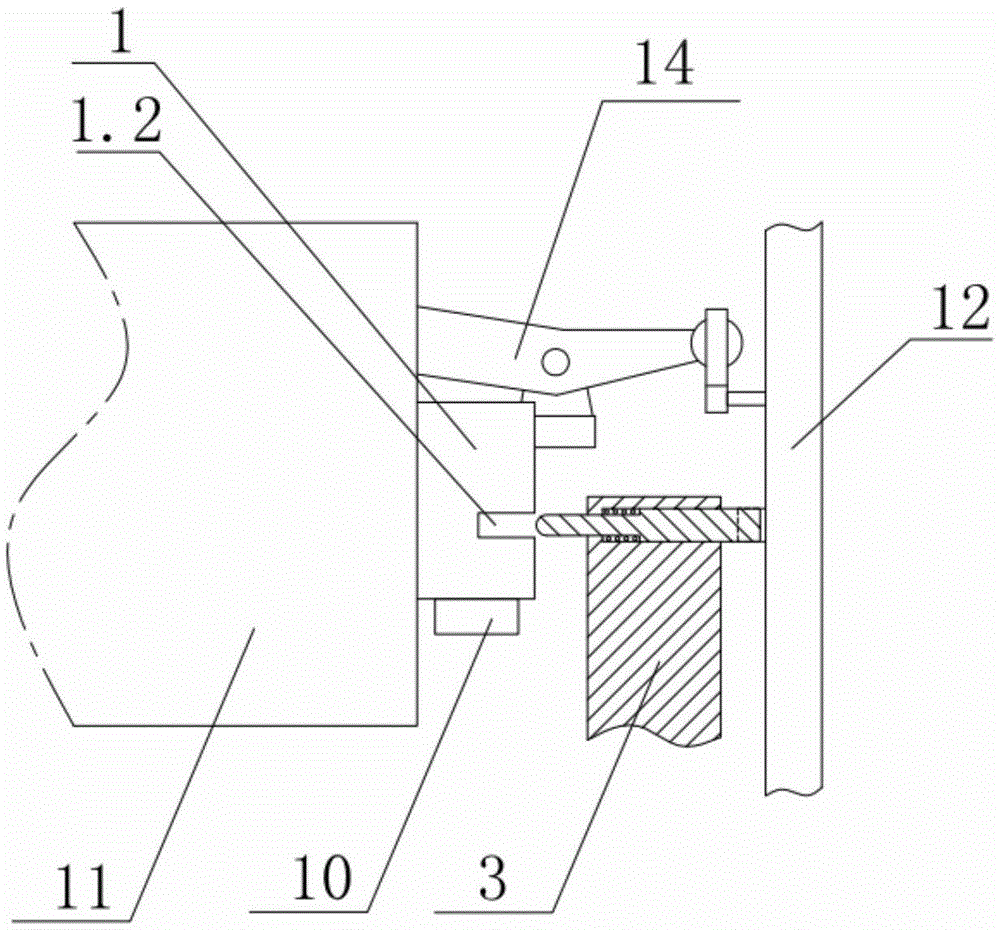

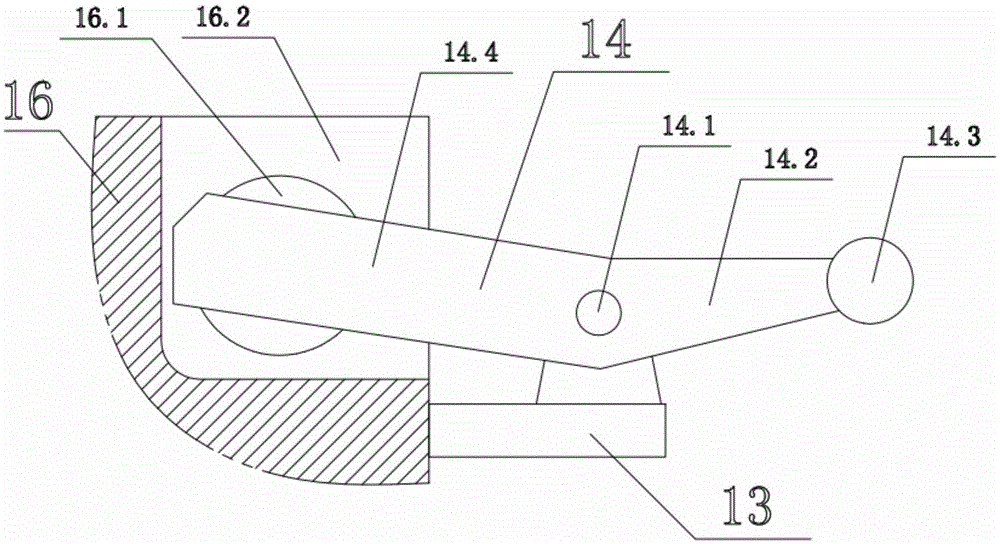

[0029] The invention provides a protective mechanism for a horizontal injection molding machine, which includes a hinged seat 13, a labor-saving lever 14 and a horizontal plate 15, the hinged seat 13 is fixed on a fixed mold 16, and the position of the fulcrum 14.1 of the labor-saving lever 14 is hinged by a rotating shaft On the hinge seat 13, the horizontal plate 15 is fixed to the machine tool sliding door 12, and the front end of the horizontal plate 15 close to the labor-saving lever 14 is bent upward to form an inclined surface 15.1. When the machine tool sliding door 12 is closed, the machine tool sliding door 12 drives the horizontal The inclined surface 15.1 of the plate 15 abuts against the force application point 14.3 on the power arm 14.2 of the labor-saving lever 14, and drives the power arm 14.2 to turn downward. Open slot 16.2, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com