Rapid mold adjusting method and mold adjusting device for injection molding machine

A technology of a mold adjusting device and an injection molding machine, which is applied in the field of injection molding machines, can solve problems affecting the precision of mold opening and closing, energy consumption, and overflow, and achieve the effects of improving work efficiency, strengthening firmness, and preventing loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: A quick mold adjustment method for an injection molding machine,

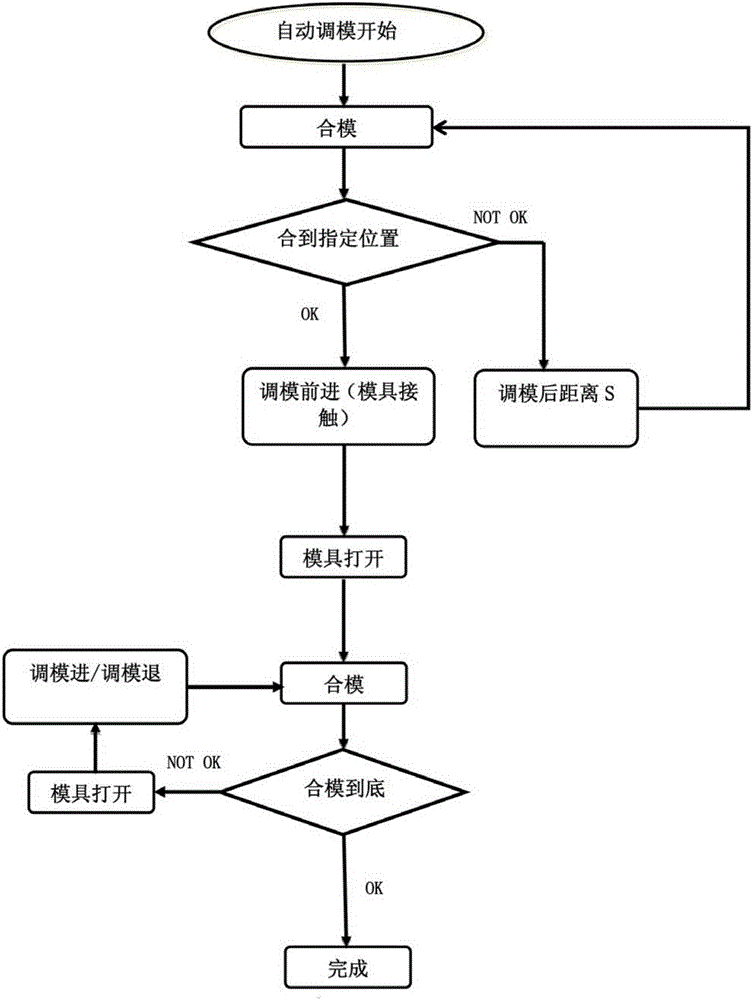

[0026] Such as figure 1 As shown, the quick mold adjustment method of injection molding machine of the present invention comprises the following steps:

[0027] Pre-set the clamping force according to the actual situation of the injection molding machine;

[0028] Calculate the required specified position according to the relationship between the preset clamping force and the elastic deformation of the mold;

[0029] Control the brake template to move to the specified position;

[0030] Judging whether the movable template and the mold are in contact with the mold after the preset mold confirmation time, if there is contact, go to the next step; if not, continue to move the movable template to the pre-designated position;

[0031] Open the mold, turn the mold adjustment gear, and adjust the pull rod to advance and retreat to achieve fine adjustment of the distance between the template an...

Embodiment 2

[0034] Embodiment 2: A quick mold adjustment device for an injection molding machine,

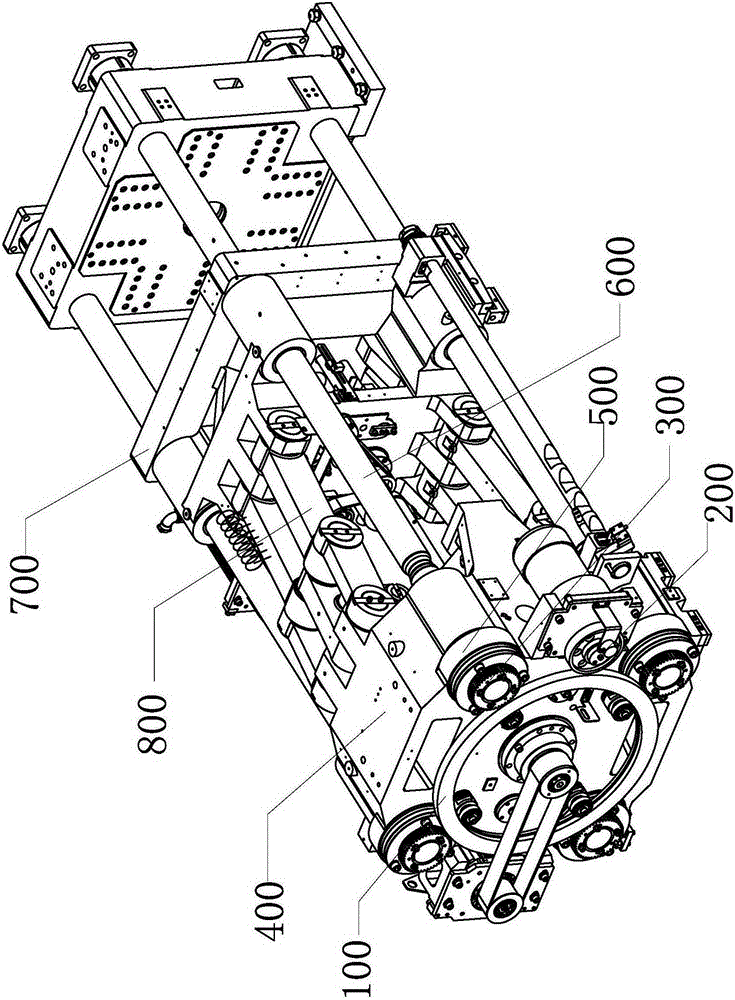

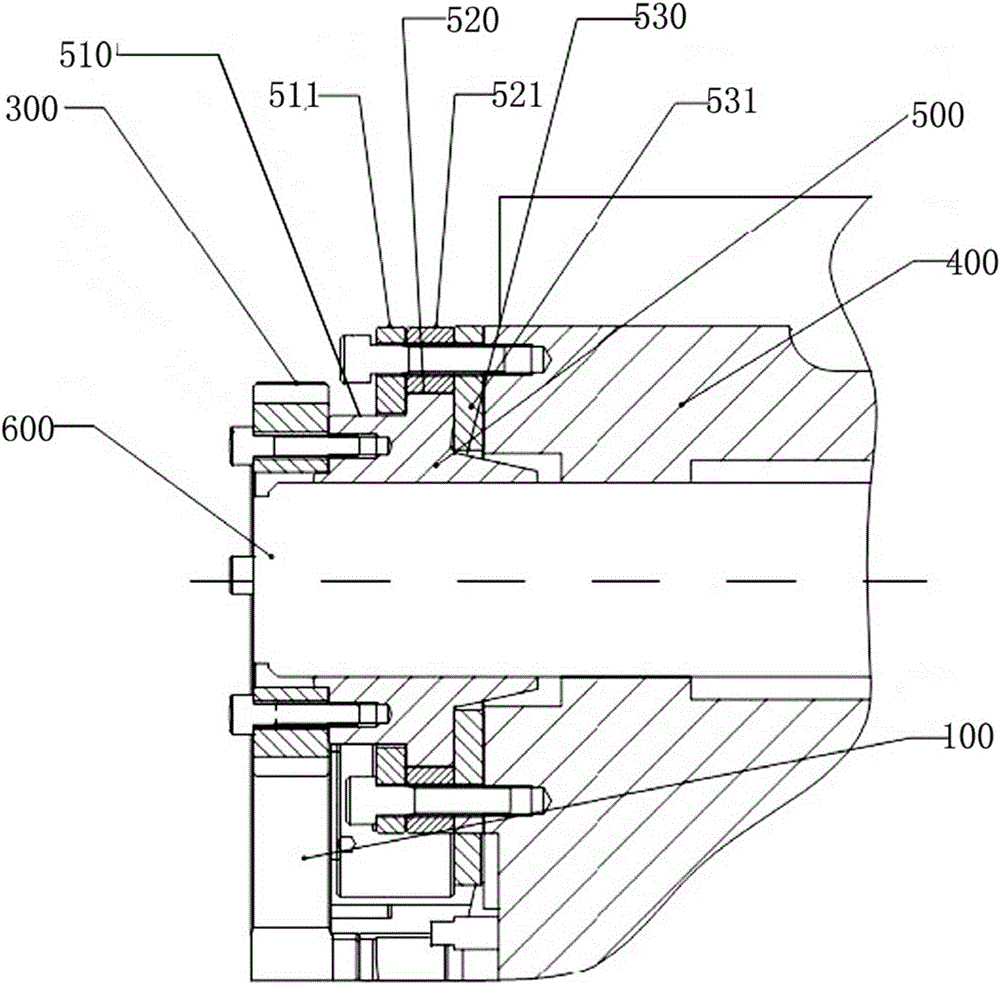

[0035] Such as figure 2 and image 3 As shown, the quick mold adjustment device of the injection molding machine of the present invention can quickly adjust the mold according to the quick mold adjustment method of the injection molding machine in the first embodiment. The mold adjustment device includes a mold adjustment motor, a large gear 100 , an encoder 200 , four mold adjustment gears 300 , a tail plate 400 , a mold adjustment screw nut 500 , a tie rod 600 and a movable template 700 . Wherein the big gear 100 and the mold-adjusting motor rotate synchronously through the belt, and the encoder 200 is electrically connected to the big gear 100. When the big gear 100 rotates, the encoder 200 starts to count; the mold-adjusting screw nut is installed on the tail plate 400, four A mode-adjusting gear 300 meshes with the large gear 100, and is arranged in a square shape on the periphery o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com