Injection molding mold

A technology of injection molding and mold cavity, which is applied to household components, household appliances, and other household appliances. It can solve the problems of non-slip function of hangers, reduce the production rate of hangers, and insufficient friction, so as to improve the appearance quality and prevent slipping. , increasing the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

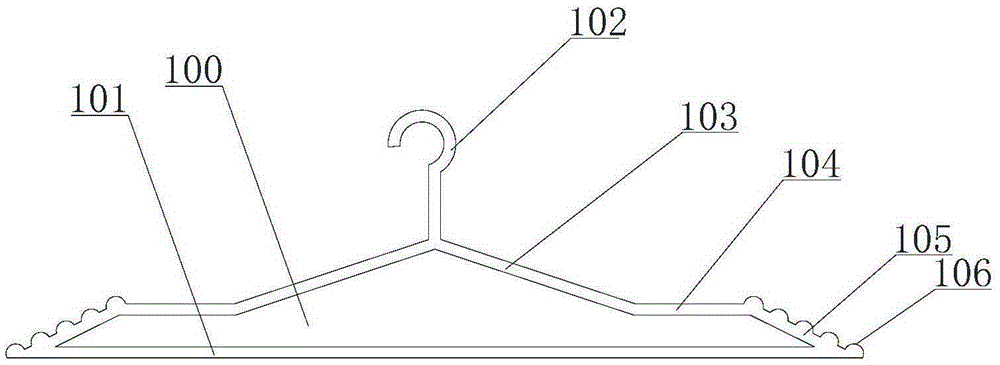

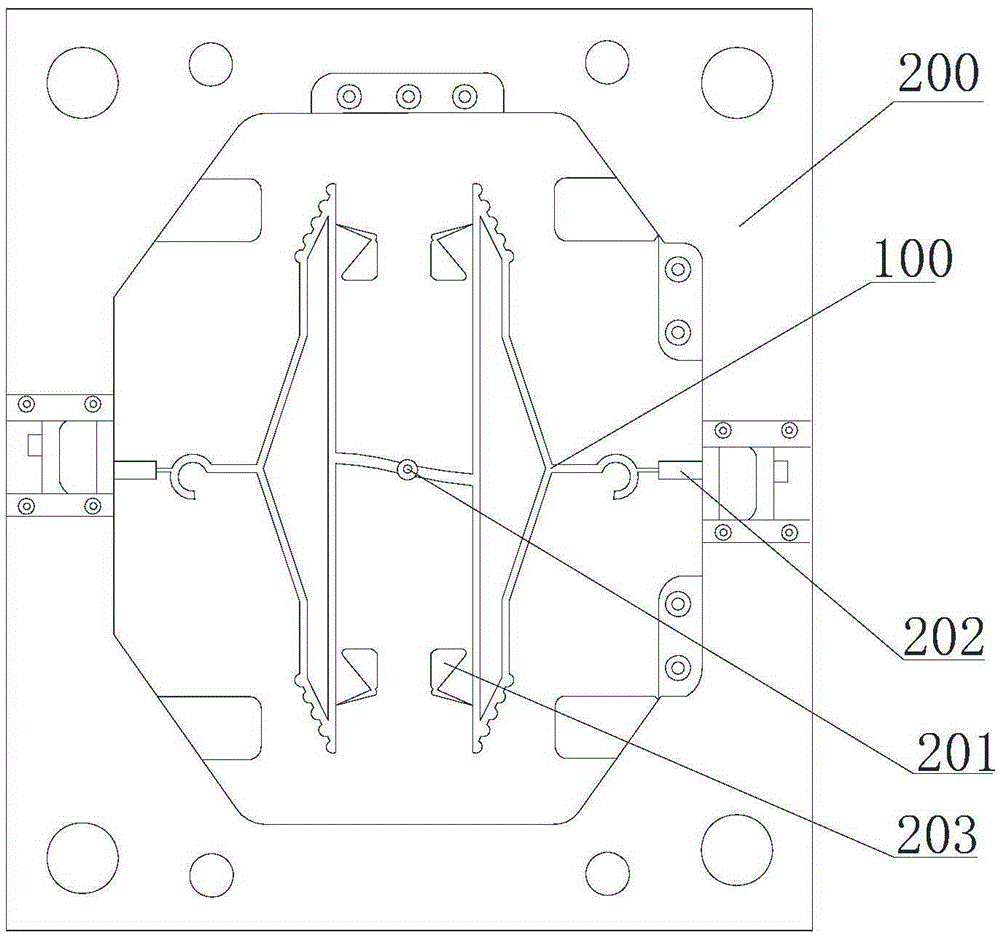

[0036] see figure 1 and figure 2, an injection molding mold, comprising an upper mold 200, a lower mold and a mold cavity 100, the mold cavity 100 is provided with a hanger cavity 101 and a hook cavity 102, the hanger cavity 101 is used to form the specific shape of the hanger, the hook mold The cavity 102 is used to form the hook part of the clothes hanger, and the hook part is used to hang the clothes hanger on the clothesline, and then hang the clothes to dry. The inclined bar cavity 103 is used to form the shoulder of the hanger, the platform cavity 104 is used to form the hanging part of the hanger, and after the formed hanger, the clothes are in contact with the hanging part, and the sawtooth cavity 105 is used to form the anti-slip part of the hanger, and the clothes are hung on the hanging part And it is in contact with the anti-slip part, which can effectively prevent the clothes from falling during the hanging process. The inclined bar cavity 103 and the platform ...

Embodiment 2

[0042] The injection molding mold provided in this embodiment has the same basic structure, principle and technical effect as that of the first embodiment. For a brief description, for the part not mentioned in this embodiment, you can refer to the corresponding content in the first embodiment. .

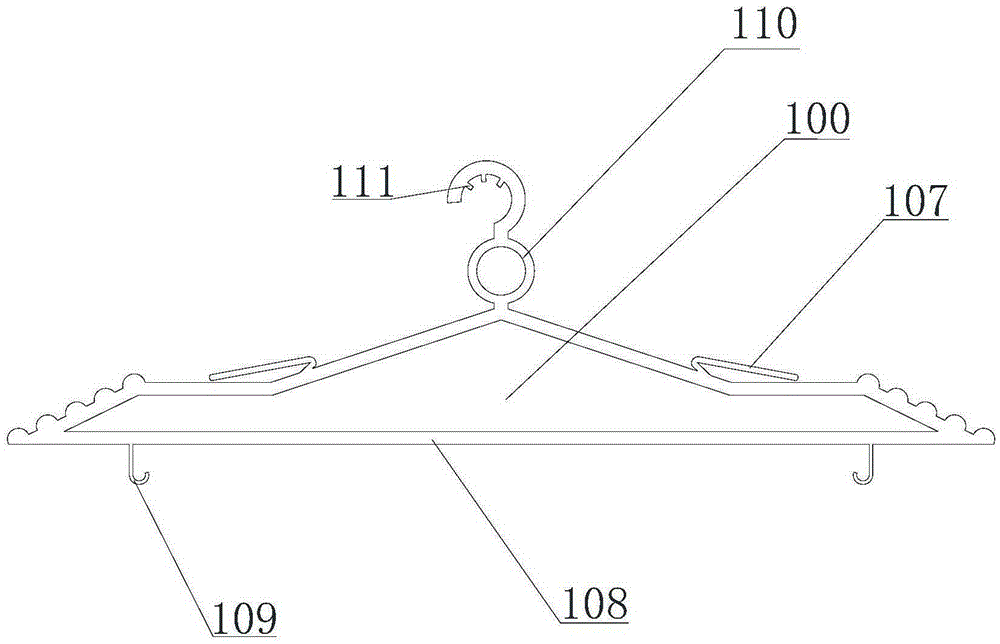

[0043] see image 3 , in this implementation, the sawtooth cavity 105 is arranged obliquely to the platform cavity 104 and protrudes from the platform cavity 104. Such a design of the mold cavity makes the anti-slip part of the formed hanger inclined downward from the hanging part, which fits the shape of the clothes more closely. To avoid the deformation of the clothes during the hanging process, at the same time, the anti-slip part protrudes from the hanging part, and the protruding part of the anti-slip part and the hanging part form an included angle with the hanging part. At the same time, when the clothes are only in contact with the hanging part and not in contact with the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com