Breaking preventing type vibrating screen

A vibrating screen and anti-break technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problem of easy breakage of the screen body, and achieve the effect of increasing the connection mode, saving cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

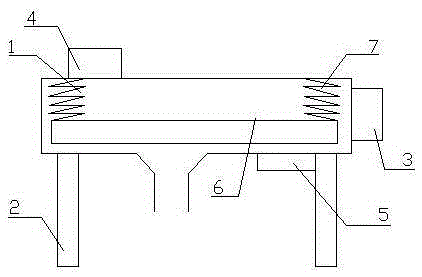

[0009] Such as figure 1 It is a schematic diagram of the structure of the present invention. The anti-break vibrating screen includes a screen box 1, a bracket 2, a vibration motor 3, a feed port 4, a discharge port 5 and a screen body 6. The upper end of the screen box 1 is provided with a feed port 4. The lower end is provided with a bracket 2 and a discharge port 5, and the screen box 1 is provided with a screen body 6, and the side section is provided with a vibrating motor 3, and the two ends of the screen body 6 are fixedly connected in the screen box 1 through a spring body 7.

[0010] First, the material enters the screen box 1 through the feed port 4 and is laid on the screen body 6 . Then start the vibrating motor 3 to make the particles on the sieve body 6 vibrate, so that the particles on the sieve body 6 vibrate and fall out of the screen box 1 through the sieve body 6 . Since the spring body 7 is used to connect the screen body 6, the connection can be provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com