ink needle

A technology of ink supply needle and needle seat, applied in printing and other directions, can solve the problem of ink leakage of ink supply needle, achieve the effect of stable detection and increase of flow circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

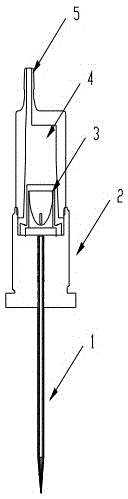

[0022] Such as figure 1 As shown, the ink supply needle includes a needle head 1, a needle seat 2, a one-way valve 3, a detection chamber 4, and an ink outlet 5. The needle head 1 is fixedly connected to the needle seat 2, and the one-way valve 3 is fixed on the needle seat 2. The valve 3 is a duckbill type, the ink flows from the top of the needle 1 to the bottom of the needle 1, and then flows to the one-way valve 3, the one-way valve is opened, the ink flows into the detection chamber 4, and then enters the ink delivery pipe from the ink outlet 5. In the case of backflow, the ink flows into the detection chamber 4 from the ink outlet 5, and since the one-way valve 3 prevents the flow of ink, the ink will not flow to the needle through the one-way valve.

Embodiment 2

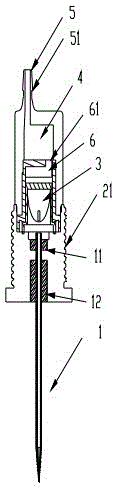

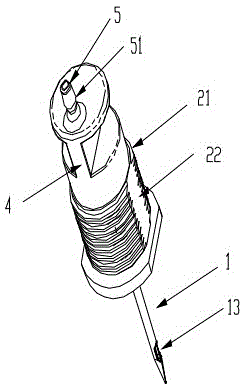

[0024] Such as figure 2 , 3 As shown in , 4, the ink supply needle includes a needle head 1, a needle seat 2, a one-way valve 3, a detection chamber 4, an ink outlet 5, and a return chamber 6. The needle head 1 has a fastener one 11, a fastener two 12, and a needle Hole 13, there is a gap between fastener one 11 and fastener two 12, so that the fixed connection between needle head 1 and needle seat 2 is more firm, needle seat 2 has thread 21, positioning gap 22, thread connection is tighter, positioning gap When the thread is fixed, the ink supply needle will not rotate, which will not affect the fixation of the ink supply needle; the one-way valve 3 is fixed on the needle seat 2, and the one-way valve 3 is duckbill type; the one-way valve 3 and the detection chamber 4 have a The reflow chamber 6, the reflow chamber has an opening 61, so that the ink enters the detection chamber through the opening 61, and the ink flow is more stable. The detection chamber is flat, which ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com