Single nut seat assembly type pulling-resistant joint

A nut seat and assembled technology, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as strong corrosion, large buoyancy of groundwater, and failure to meet architectural design requirements, so as to improve performance and increase tensile strength and the effect on flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

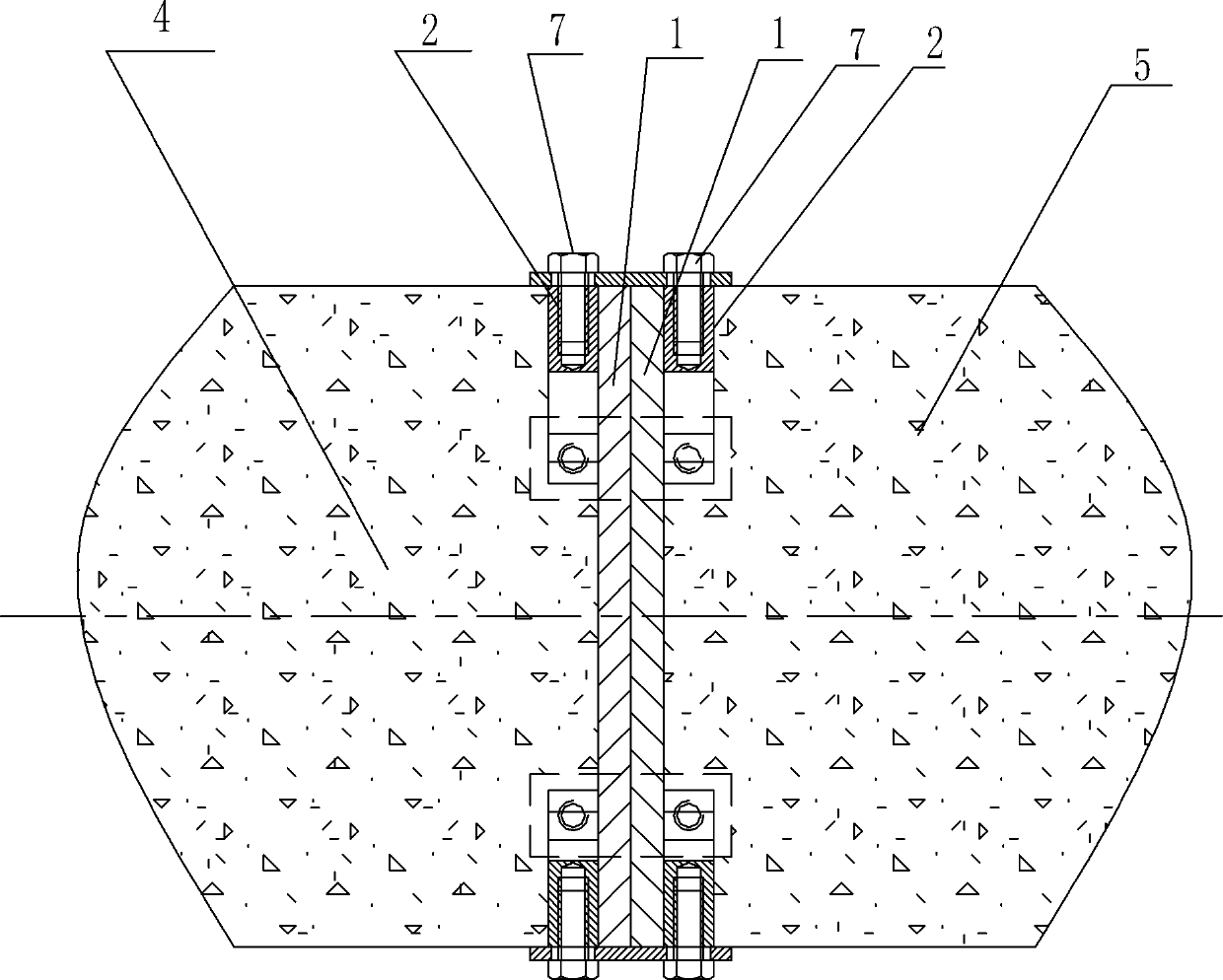

[0012] The present invention will be further explained below in conjunction with the drawings.

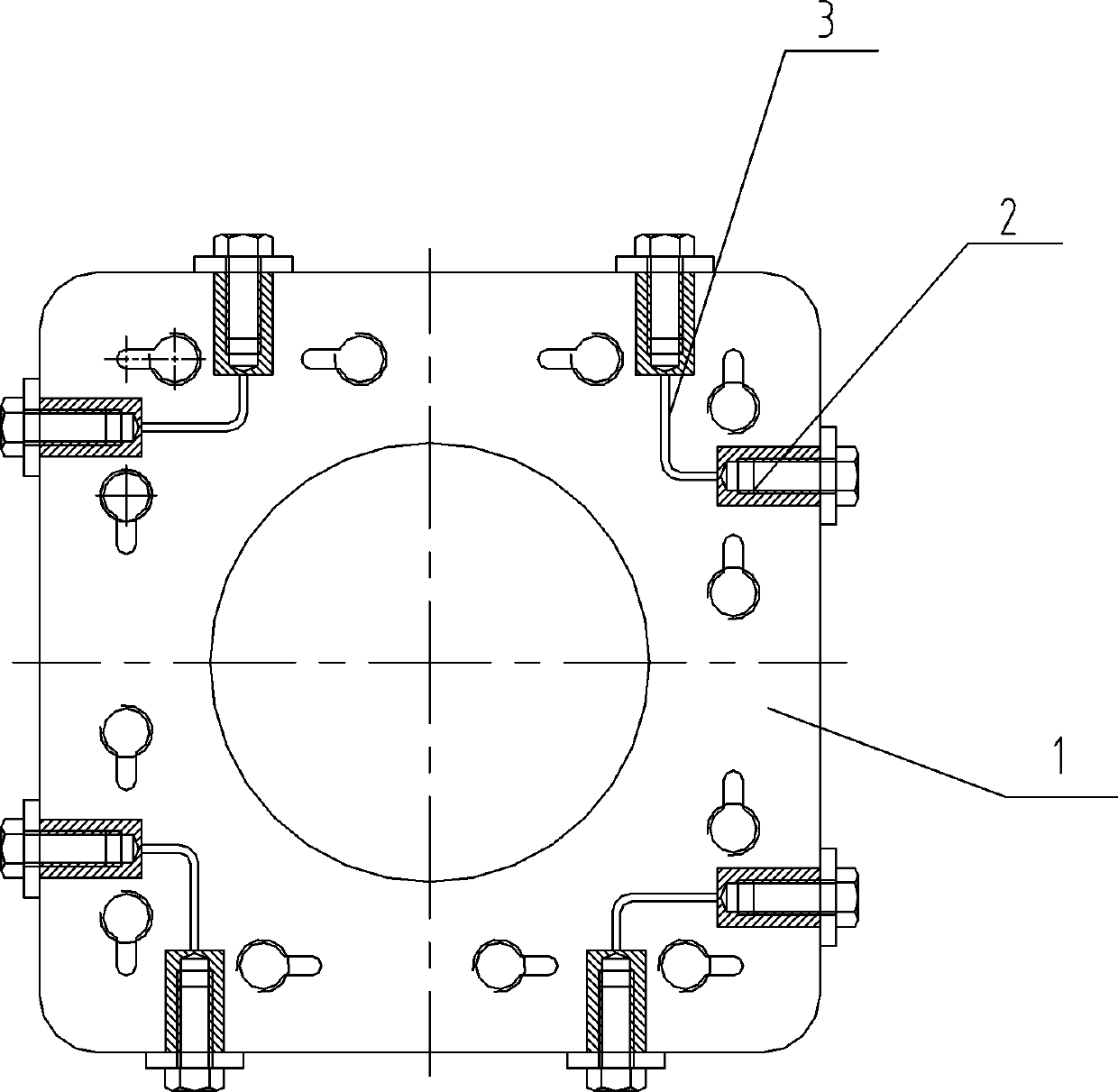

[0013] Such as figure 1 As shown, a single-nut seat assembly type anti-pulling joint includes a square end plate 1 and two nut holders 2 arranged on each side of the back of the end plate 1, all the nut holders 2 have openings facing outward , An anti-rotation connecting plate 3 is connected between two adjacent nut seats 2 on two adjacent sides. The two ends of the anti-rotation connecting plate 3 are respectively welded to the bottom ends of the two nut seats.

[0014] Wherein, the anti-rotation connecting plate 3 can be two pieces, one end of each plate is fixed to the bottom end of the nut base 2, and the other end is fixed to the other plate for welding; the included angle between the two anti-rotation connecting plates 3 is 90°; the anti-rotation connecting plate 3 can also be a steel plate bent at a right angle.

[0015] The two ends of the anti-rotation connecting plate 3 are we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com