A method for quickly and uniformly adding diluent and inhibitor when stirring fails

A diluent and inhibitor technology, applied in the research field of active prevention and control measures, can solve the problems of high viscosity, non-uniform dispersion of diluents and inhibitors, and it is difficult to prevent the reaction from running out of control, so as to achieve stable use and prevent The effect of a runaway reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention discloses a method for quickly and uniformly adding diluent and inhibitor when stirring fails. In order to make the advantages and technical solutions of the invention clearer and clearer, the invention will be described in detail below in conjunction with specific examples.

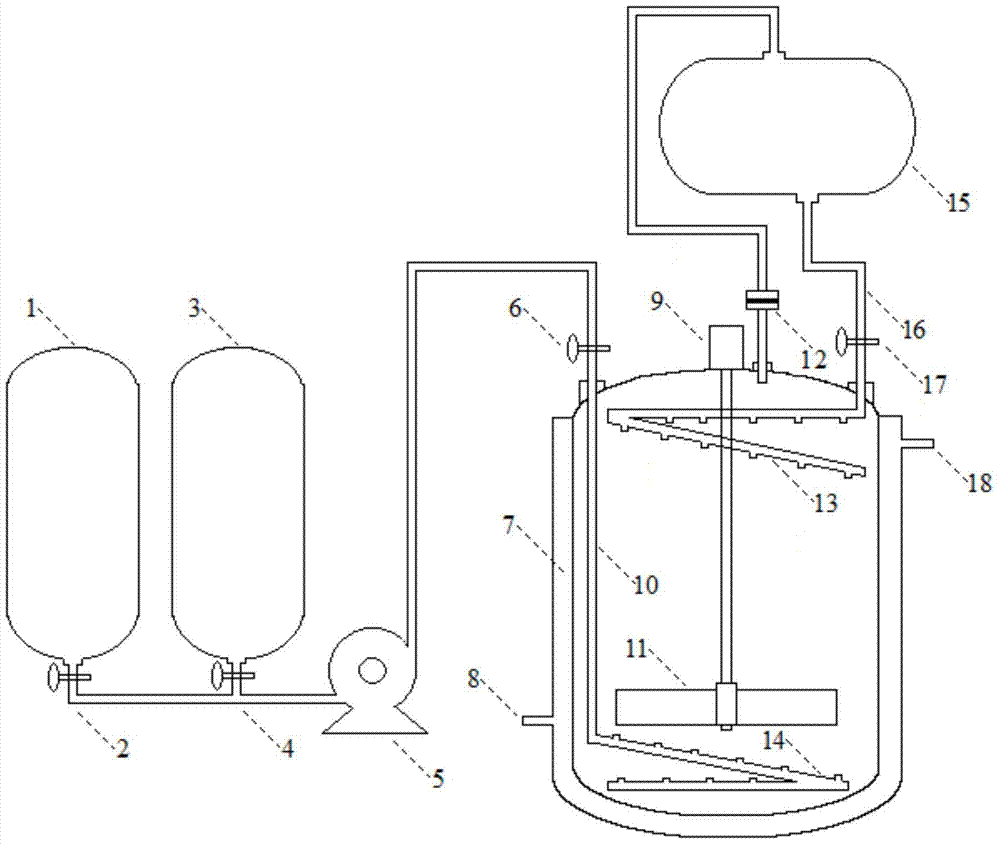

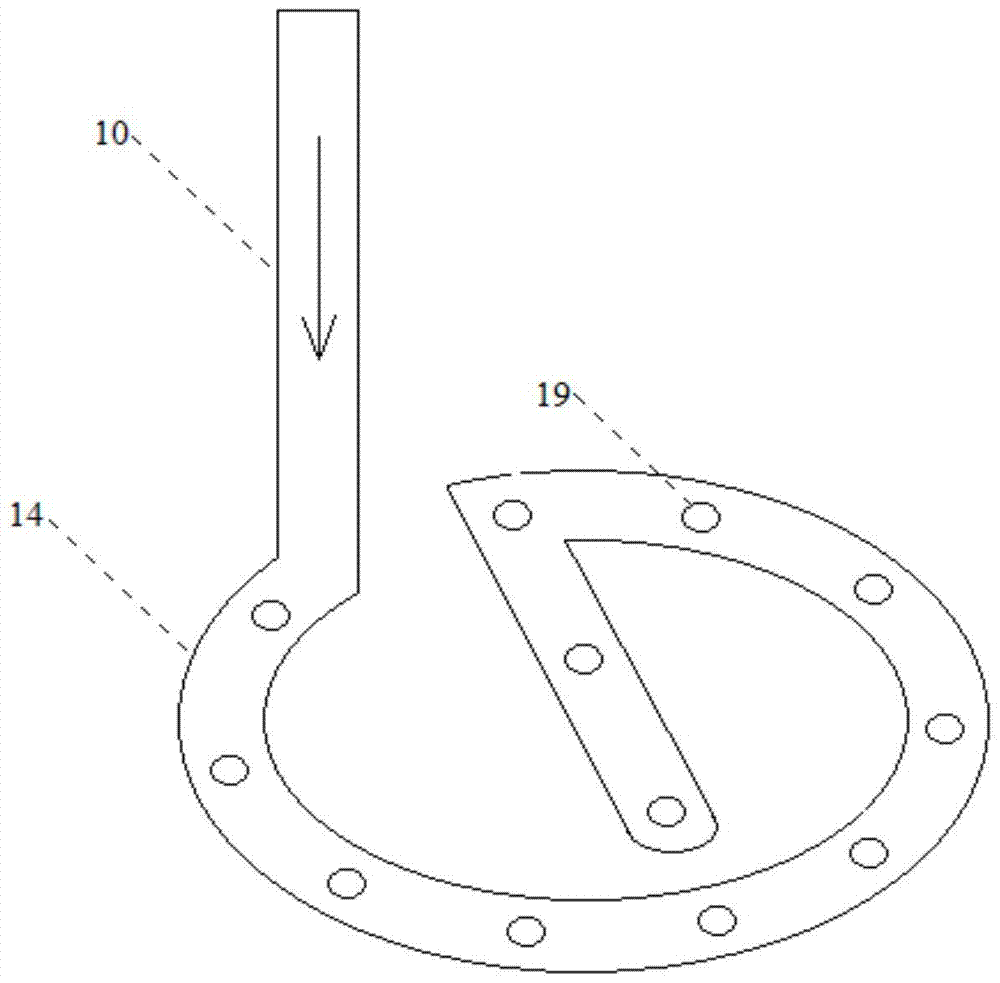

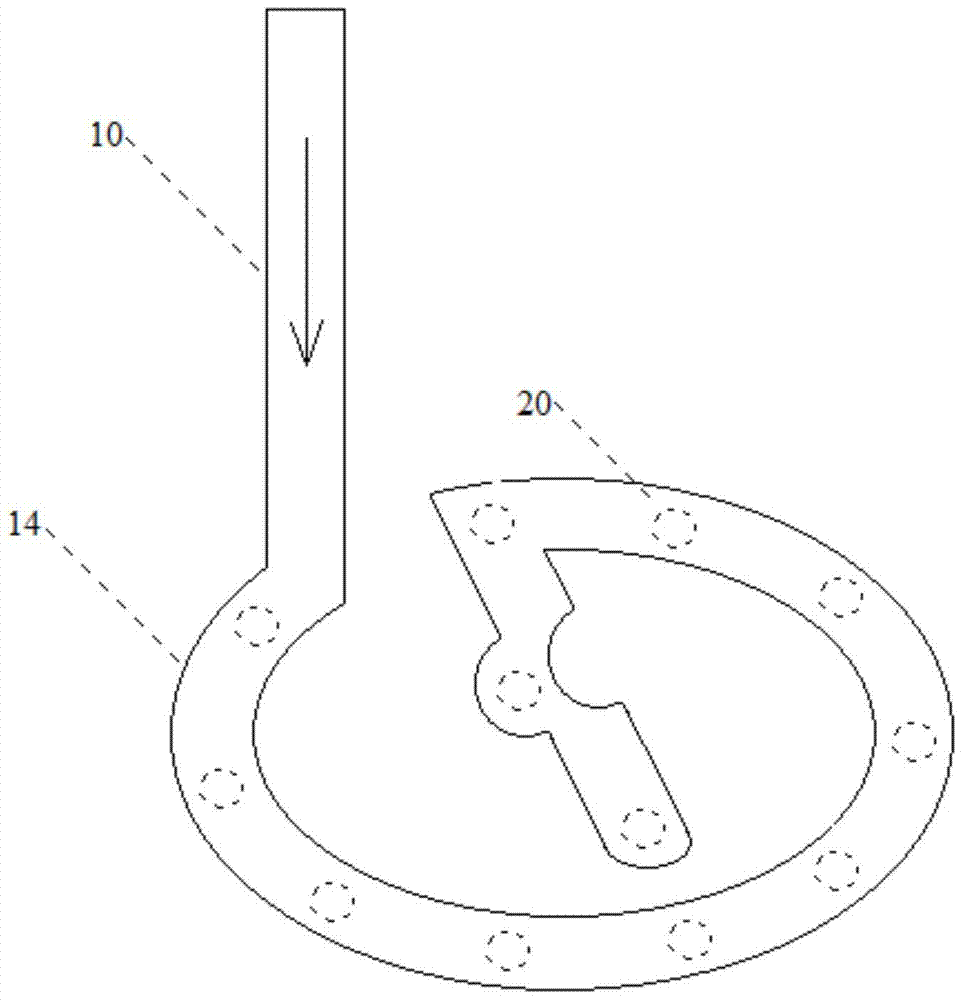

[0025] First, the selected device of the present invention is described in detail. The present invention is a device that quickly and evenly adds diluent and inhibitor when the stirring fails, such as figure 1 As shown, it includes storage tank one 1 for placing inhibitor, storage tank two 3 for placing diluent, reaction tank and storage tank three 15 for placing low-temperature raw material solvent, wherein storage tank one 1 and the bottom of storage tank 2 and 3 are respectively provided with an outlet end 1 and an outlet end 2, and the outlet end 1 and the outlet end 2 are connected with a pipeline 1 and a pipeline 2, and a valve 2 and a valve 4 are respectively arranged on the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com