Preparation device used for refining olefin catalysts of reforming oil

A preparation device and de-olefin technology, which is applied in the fields of refined hydrocarbon oil, petroleum industry, chemical instruments and methods, etc., can solve the problems of long reaction channel, unfavorable reaction speed, influence on catalyst stability, etc., and achieve the effect of preventing local concentration from being too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

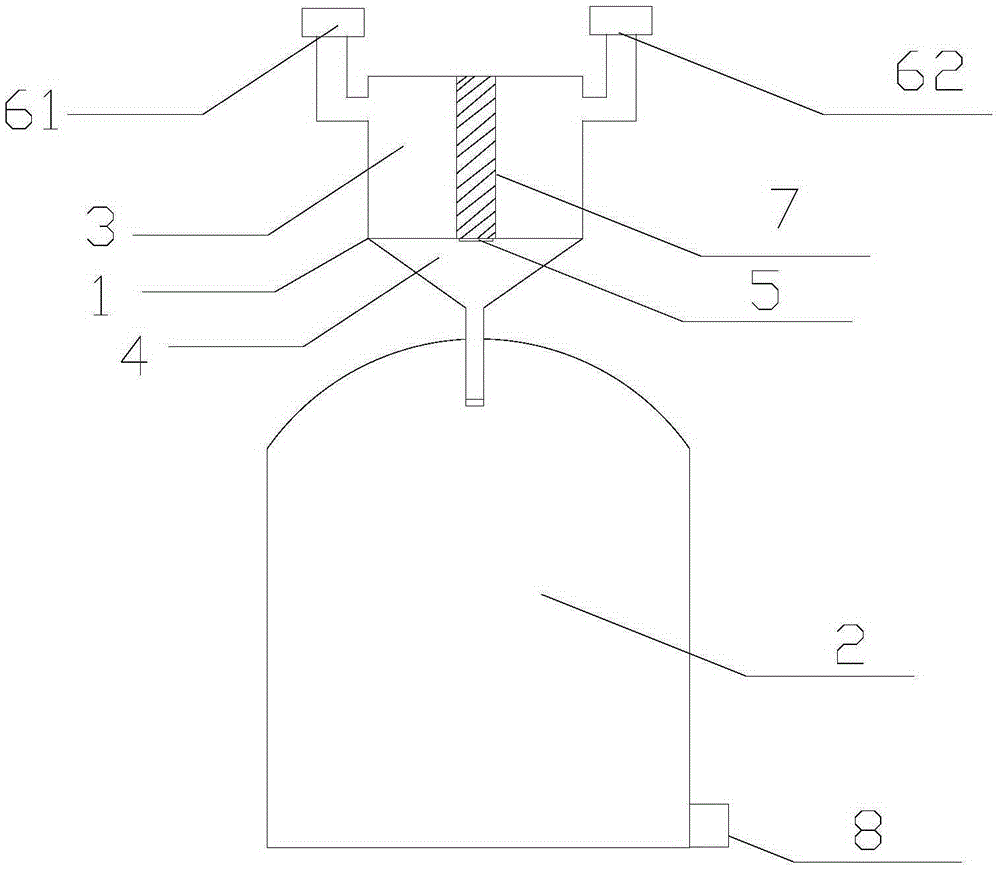

[0008] Such as figure 1 A preparation device for refining reformed oil deolefination catalyst shown includes a reaction flow guide 1 and a liquid collection tank 2, and the reaction flow guide 1 is arranged on the top of the liquid collection tank 2, and the shape is funnel-shaped including The upper part 3 and the conical bottom 4 of the cuboid, the upper part 3 and the bottom 4 are connected through the through hole 5, the upper part 3 is provided with feed ports 61, 62 on both sides, and the movable rubber plug 7 is arranged inside, and the movable rubber plug 7 is connected with the upper part 3, etc. High, and the side length of the movable rubber plug 7 is greater than the diameter of the through hole 5, the bottom of the liquid collection tank 2 is provided with a discharge port 8, and the position of the through hole 5 is located in the center of the bottom surface of the upper part 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com