A membrane-like fenton process for wastewater treatment

A technology of wastewater treatment and membrane method, which is applied in the field of membrane-like Fenton process, can solve the problems of high energy consumption, low ozone solubility, high power consumption, etc., and achieve the effects of high treatment efficiency, simple operation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

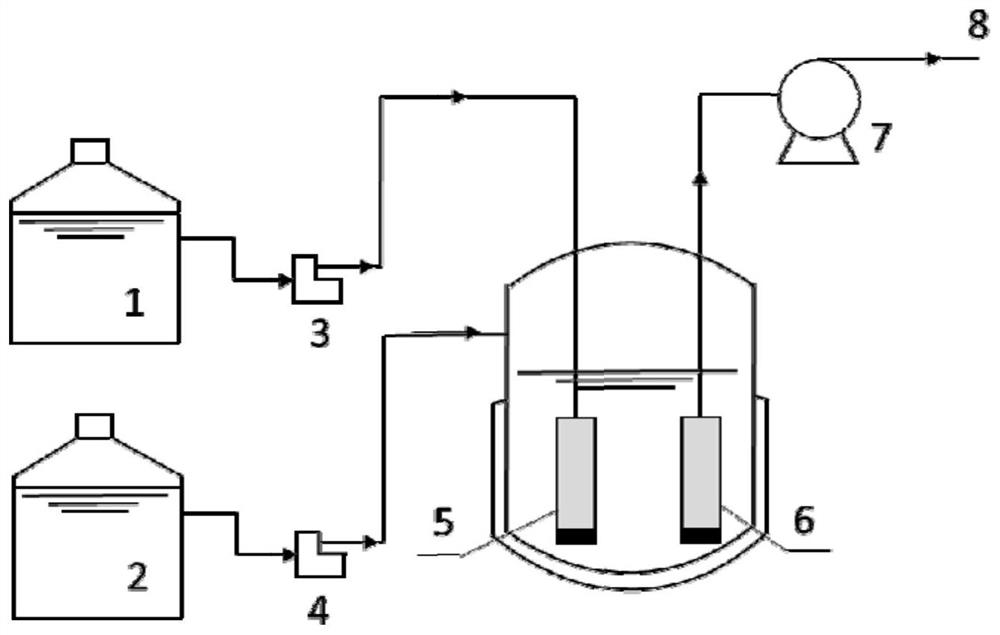

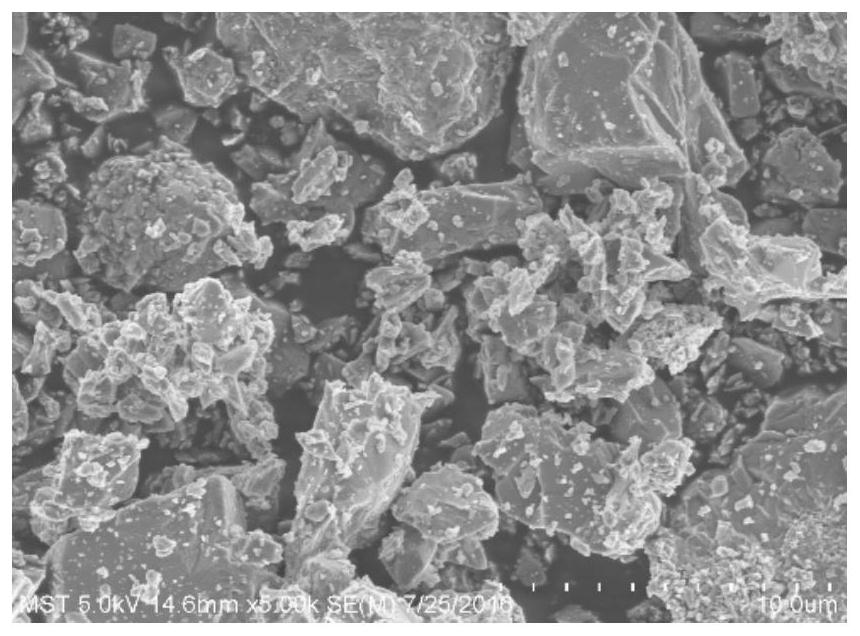

[0034] Take reverse osmosis concentrated water from a factory, and its wastewater COD is 350mg / L. Amount of 5L papermaking wastewater in figure 1 In the reactor, add 0.5g / L solid catalyst MnO 2 ,Such as image 3 As shown, wastewater and H were continuously fed into the reactor through a peristaltic pump 2 o 2 , using ZrO with a pore size of 50nm in the reactor 2 Single channel ceramic membrane for distribution of H 2 o 2 , control H 2 o 2 (mg / L):COD 进水 (mg / L) was 1.25; reacted under normal pressure at 30°C for 40 minutes, continuously separated the catalyst with a 50nm zirconia ceramic membrane in the reactor through a centrifugal pump, and measured the COD degradation rate of wastewater. After calculation, the COD degradation rate of papermaking wastewater was 52.57 %.

Embodiment 2

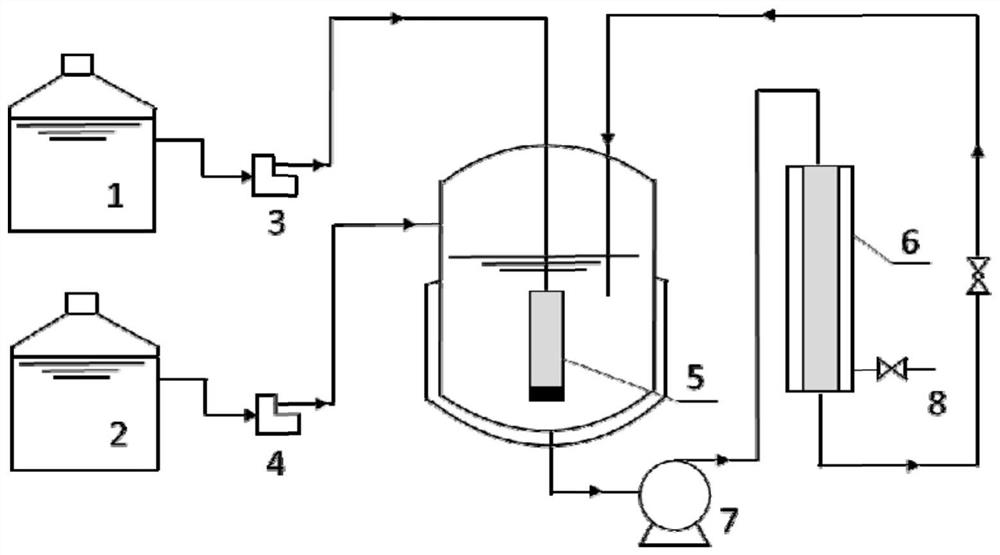

[0036] Take the biochemical waste water of a certain factory, and its waste water COD is 318mg / L. Amount of 5L papermaking wastewater in figure 2 In the reactor, add 0.5g / L solid catalyst LaMnO 3 ,Such as Figure 5 As shown, wastewater and H were continuously fed into the reactor through a peristaltic pump 2 o 2 , using the pore size of 200nm ZrO in the reactor 2 Single channel ceramic membrane for distribution of H 2 o 2 , control H 2 o 2 (mg / L):COD 进水 (mg / L) is 0.78; react under normal pressure at 30°C for 60 minutes, use a centrifugal pump to make the wastewater flow from the reactor through the pipeline into the 20nm polysulfone organic membrane outside the reactor, continuously separate the catalyst, and measure the COD degradation rate of the wastewater , by calculation, the COD degradation rate of papermaking wastewater is 55.97%.

Embodiment 3

[0038] Take the biochemical wastewater from a certain factory, the COD of the wastewater is 318mg / L. Amount of 5L papermaking wastewater in figure 1 In the reactor, add 1.2g / L solid catalyst LaFeO 3 ,Such as Figure 6 As shown, wastewater and H were continuously fed into the reactor through a peristaltic pump 2 o 2 , using a reactor with a pore size of 200nmAl 2 o 3 Single channel ceramic membrane for distribution of H 2 o 2 , control H 2 o 2 (mg / L):COD 进水 (mg / L) is 0.45; react under normal pressure at 30°C for 120min, use a centrifugal pump to make the 500nm alumina ceramic membrane in the reactor continuously separate the catalyst, and measure the COD degradation rate of wastewater. After calculation, the COD degradation rate of papermaking wastewater is 70.88 %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com