Mechanical assist mechanism for active pedestrian safety latch

A technology of mechanical components and latches, applied in the field of vehicle safety systems, can solve the problems of replacement cost and safety, reliability and reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

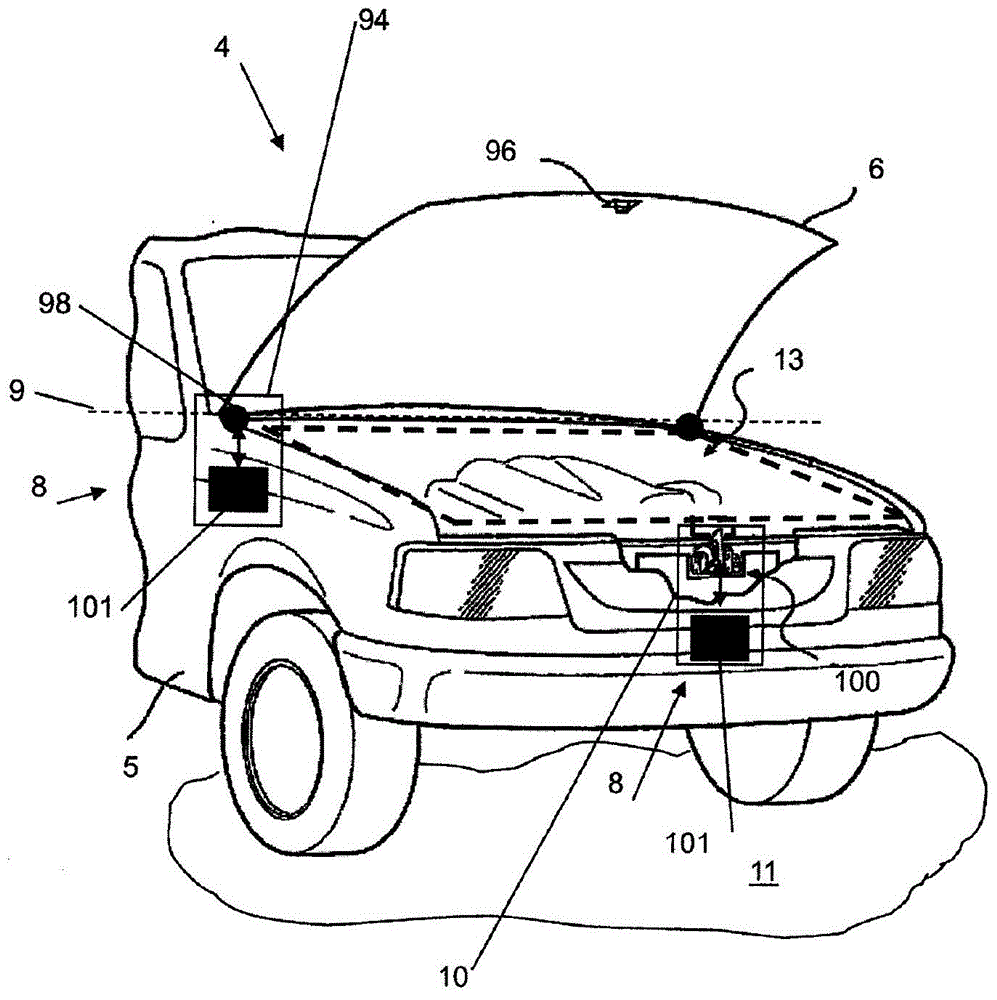

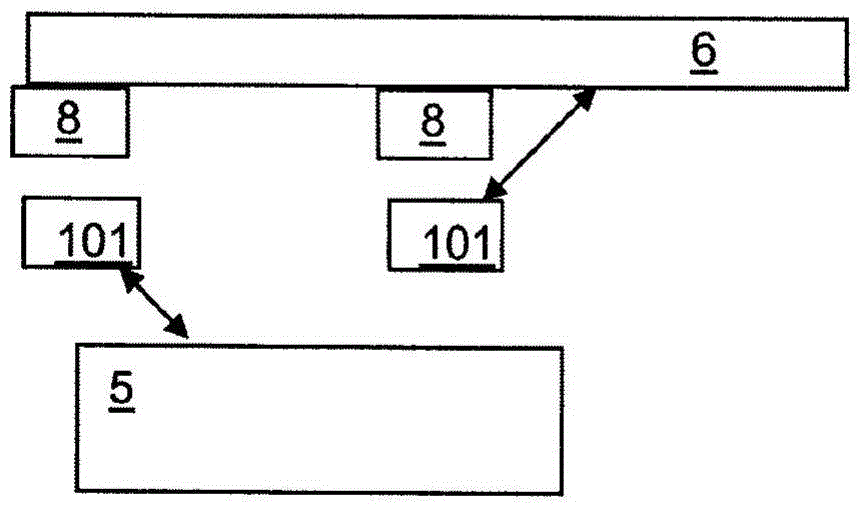

[0046] refer to Figure 1A, shows a vehicle 4 having a body 5 with one or more closure panels 6 . The closure panel 6 is connected to the vehicle body 5 via one or more panel operating components 8 such as, but not limited to, hinges 98 and / or latches 100 (e.g., for locking the closure panel 6 when closed). held in the closed position or used to hold the closure panel 6 in the open position when opened). It is also appreciated that the hinge 98 may be configured as an offset hinge that may be configured to bias the closure panel 6 toward the open position and / or toward the closed position. In addition, the panel operating part 8 may be configured as a lift assist system comprising one or more struts not shown, such as are used in rear lift gate systems. The closure panel 6 may have a mating latch member 96 (e.g., a striker) mounted on the closure panel 6 for latching with a corresponding panel operating member 8 (e.g., a latch) mounted on the body 5. ) connection. Alternati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com