Iron-nitrogen-codoped porous carbon catalyst for proton exchange membrane fuel cell and method of iron-nitrogen-codoped porous carbon catalyst

A proton exchange membrane, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as failure to exert catalytic performance, reduce catalyst costs, and destroy active components, and achieve strong resistance to methanol poisoning. Catalytic performance, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method for an iron-nitrogen co-doped porous carbon catalyst for a proton exchange membrane fuel cell, specifically comprising the following steps:

[0031] (1) 6.0mmol of 2-fluoroaniline and 12.0mmol of FeCl 3 At the same time, add it to 20mL deionized water and stir it magnetically at a speed of 500rpm for 10min to form a uniform mixture;

[0032] (2) Transfer the mixed solution in step (1) to a steel hydrothermal reaction kettle embedded with a polytetrafluoroethylene inner sleeve, and conduct a hydrothermal reaction at 180° C. for 4 hours under sealed conditions; put the hydrothermal reaction kettle in Naturally cool to room temperature in the air, then filter, and wash the obtained filter residue with ethanol and deionized water for 3 times; finally, dry the cleaned filter residue in a vacuum oven at 50°C for 24 hours to obtain a large number of FeOOH nanoparticles embedded inside. Crystalline poly-2-fluoroaniline flakes with a structure such as figure...

Embodiment 2

[0041] A preparation method for an iron-nitrogen co-doped porous carbon catalyst for a proton exchange membrane fuel cell, specifically comprising the following steps:

[0042] (1) 5.0mmol of 2-fluoroaniline and 12.0mmol of FeCl 3 Add to 20mL deionized water, and magnetically stir at 500rpm for 10min to form a uniform mixture;

[0043] (2) Transfer the mixed solution in step (1) to a steel hydrothermal reaction kettle embedded with a polytetrafluoroethylene inner sleeve, and conduct a hydrothermal reaction at 180° C. for 4 hours under sealed conditions; put the hydrothermal reaction kettle in Naturally cool to room temperature in the air, then filter, and wash the obtained filter residue with ethanol and deionized water for 3 times; finally, dry the cleaned filter residue in a vacuum oven at 50°C for 24 hours to obtain a large number of FeOOH nanoparticles embedded inside. Crystalline poly-2-fluoroaniline platelets.

[0044] (3) the poly 2-fluoroaniline flakes that are embed...

Embodiment 3

[0047] A preparation method for an iron-nitrogen co-doped porous carbon catalyst for a proton exchange membrane fuel cell, specifically comprising the following steps:

[0048] (1) 6.0mmol of 2-fluoroaniline and 10.0mmol of FeCl 3 At the same time, add it to 20mL deionized water and stir it magnetically at a speed of 500rpm for 10min to form a uniform mixture;

[0049] (2) Transfer the mixed solution in step (1) to a steel hydrothermal reaction kettle embedded with a polytetrafluoroethylene inner sleeve, and conduct a hydrothermal reaction at 180° C. for 4 hours under sealed conditions; put the hydrothermal reaction kettle in Naturally cool to room temperature in the air, then filter, and wash the obtained filter residue with ethanol and deionized water for 3 times; finally, dry the cleaned filter residue in a vacuum oven at 50°C for 24 hours to obtain a large number of FeOOH nanoparticles embedded inside. Crystalline poly-2-fluoroaniline platelets.

[0050] (3) the poly 2-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

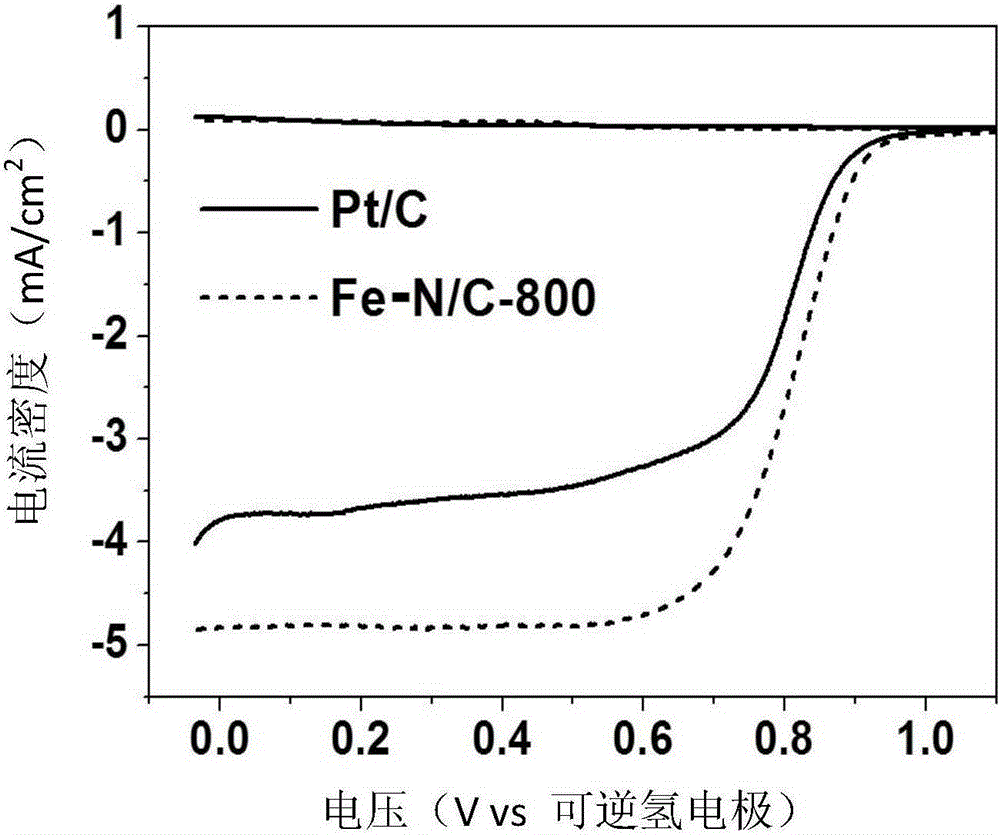

| Limiting current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com