Nonlinear fitting method for cooling process of polymeric phase change material

A nonlinear fitting, phase change material technology, applied in the field of polymer phase change materials, to achieve the effect of good fitting accuracy and good fitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

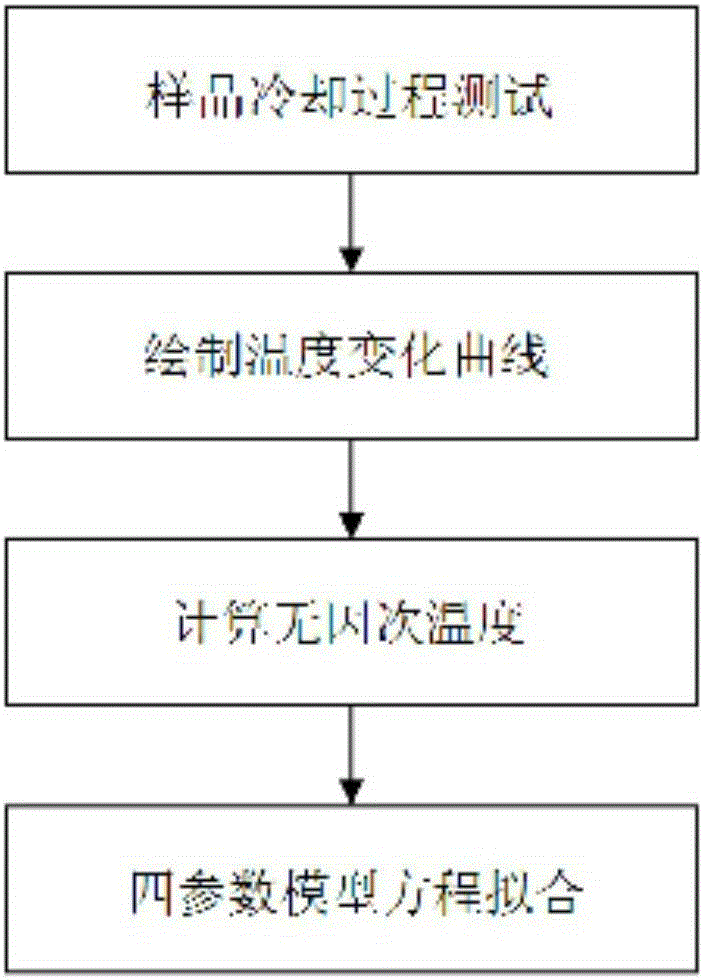

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the inventive method comprises the following steps:

[0021] (1) Take 2.0g of polypropylene as the sample to be tested, heat the sample to be tested to an initial temperature of 220°C and keep it at this temperature for 15 minutes to ensure that the sample is completely melted, and then quickly transfer the sample to water at a temperature of 25°C At the same time, a T-type thermocouple is inserted into the geometric center area of the molten sample, and the temperature change value of the sample to be tested is collected in real time during the entire cooling process, and the test is repeated 3 times;

[0022] (2) According to the temperature value and time value data collected in step (1), draw a temperature-time change curve, i.e. a "cooling curve";

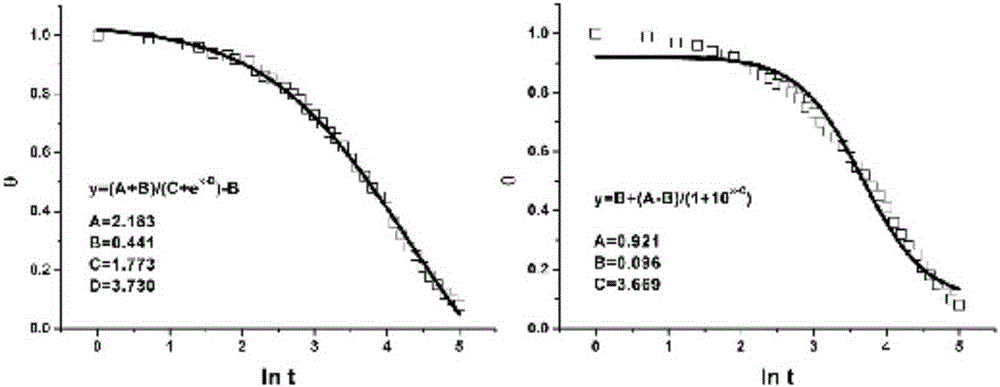

[0023] (3) Carry out dimensionless processing on the above cooling curve, take dimensionless temperature θ=(T–T 2 ) / (T 1 –T 2 ), where T 1 is the initial cooling temperature, T 2 is the cooling medi...

Embodiment 2

[0026] Embodiment 2: method of the present invention comprises the following steps:

[0027] (1) Take 1.0g of polyethylene as the sample to be tested, heat the sample to be tested to the initial temperature of 210°C and keep it at this temperature for 15 minutes to ensure that the sample is completely melted, and then quickly transfer the sample to water at a temperature of 20°C At the same time, a T-type thermocouple is inserted into the geometric center area of the molten sample, and the temperature change value of the sample to be tested is collected in real time during the entire cooling process, and the test is repeated 4 times;

[0028] (2) According to the temperature value and time value data collected in step (1), draw a temperature-time change curve, i.e. a "cooling curve";

[0029] (3) Carry out dimensionless processing on the above cooling curve, take dimensionless temperature θ=(T–T 2 ) / (T 1 –T 2 ), where T 1 is the initial cooling temperature, T 2 is the c...

Embodiment 3

[0032] Embodiment 3: method of the present invention comprises the following steps:

[0033](1) Take 2.0g of polylactic acid as the sample to be tested, heat the sample to be tested to an initial temperature of 200°C and keep it at this temperature for 15 minutes to ensure that the sample is completely melted, and then quickly transfer the sample to water at a temperature of 30°C At the same time, a T-type thermocouple is inserted into the geometric center area of the molten sample, and the temperature change value of the sample to be tested is collected in real time during the entire cooling process, and the test is repeated 3 times;

[0034] (2) According to the temperature value and time value data collected in step (1), draw a temperature-time change curve, i.e. a "cooling curve";

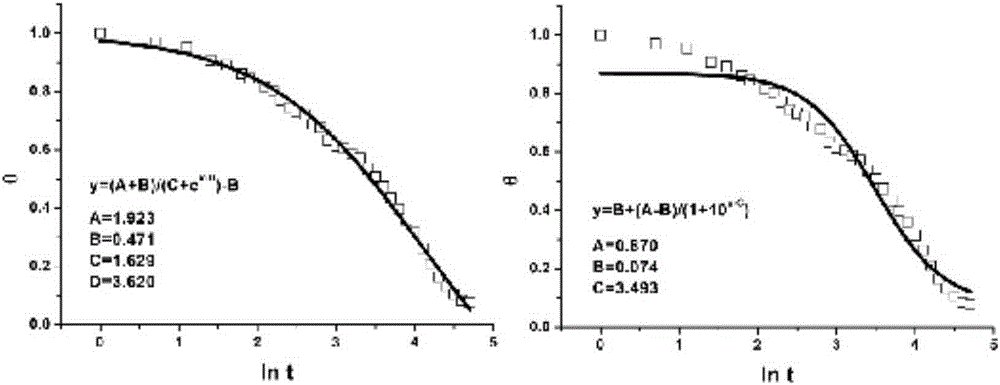

[0035] (3) Carry out dimensionless processing on the above cooling curve, take dimensionless temperature θ=(T–T 2 ) / (T 1 –T 2 ), where T 1 is the initial cooling temperature, T 2 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com