A closed-loop control method for automatic dimensioning of CNC machine tools

A CNC machine tool, closed-loop control technology, applied in computer control, program control, general control system, etc., can solve the problems of complex system, affecting stability, wrong sizing, etc., and achieve the effect of simple control system and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

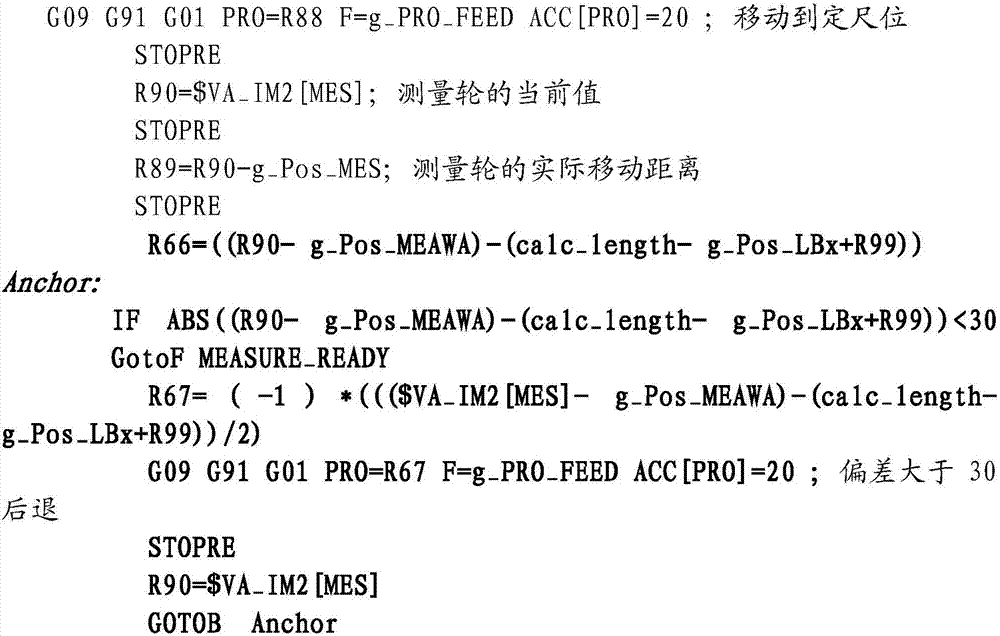

[0015] The following is an example of a saw-drilling combined CNC machine tool. The workpiece to be processed is a steel rail, the predetermined travel distance is 100 meters, and the control accuracy is plus or minus 30 mm.

[0016] This equipment adopts Siemens' numerical control system 840D as the core control unit.

[0017] The 840D control system can be briefly summarized as MCP operation unit, NCU operation unit, PLC logic processing unit and drive motor unit. With the NCU operation unit as the core, the MCP operation unit, NCU operation unit and PLC logic processing unit are connected through the system bus; the NCU operation unit and the drive motor unit are connected to exchange data through the drive bus. At the same time, the NC program in the NCU controls each drive shaft and the sizing system to achieve precise sizing.

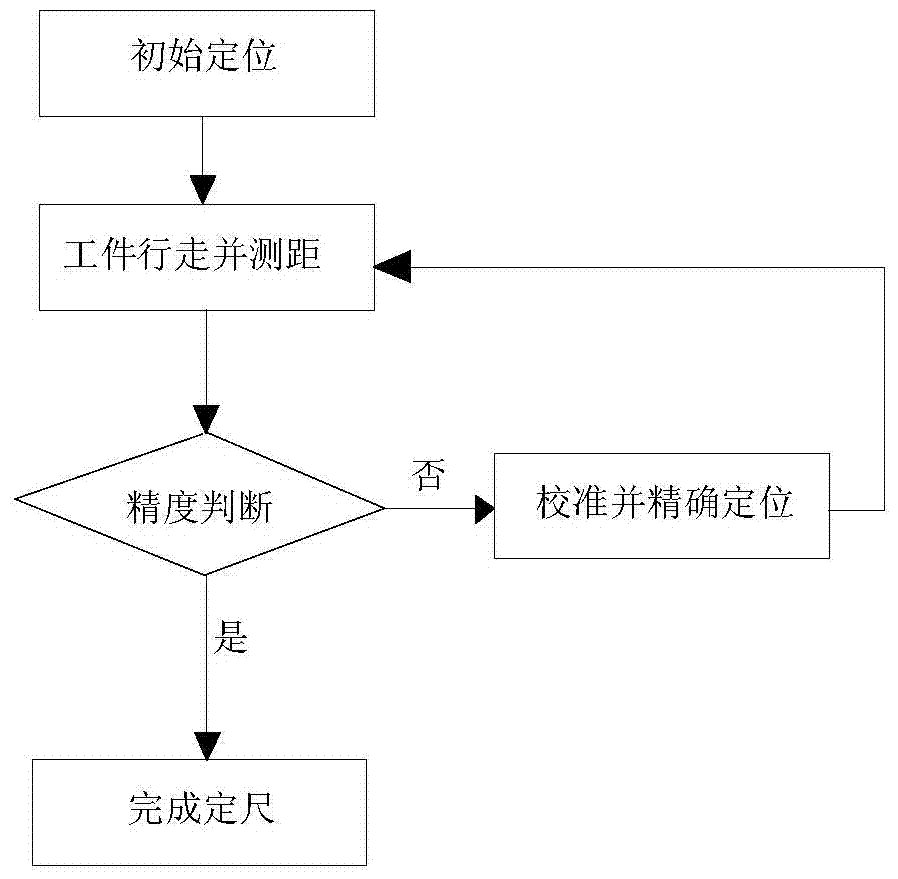

[0018] like figure 1 As shown in the method flow, the automatic sizing closed-loop control method of the CNC machine tool includes the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com