A friction type automatic turning device

A kind of cranking device and friction type technology, which is applied to safety devices, components of pumping devices for elastic fluids, non-variable-capacity pumps, etc. Coal mine underground needs and other issues, to achieve the effect of convenient operation, simple overall structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

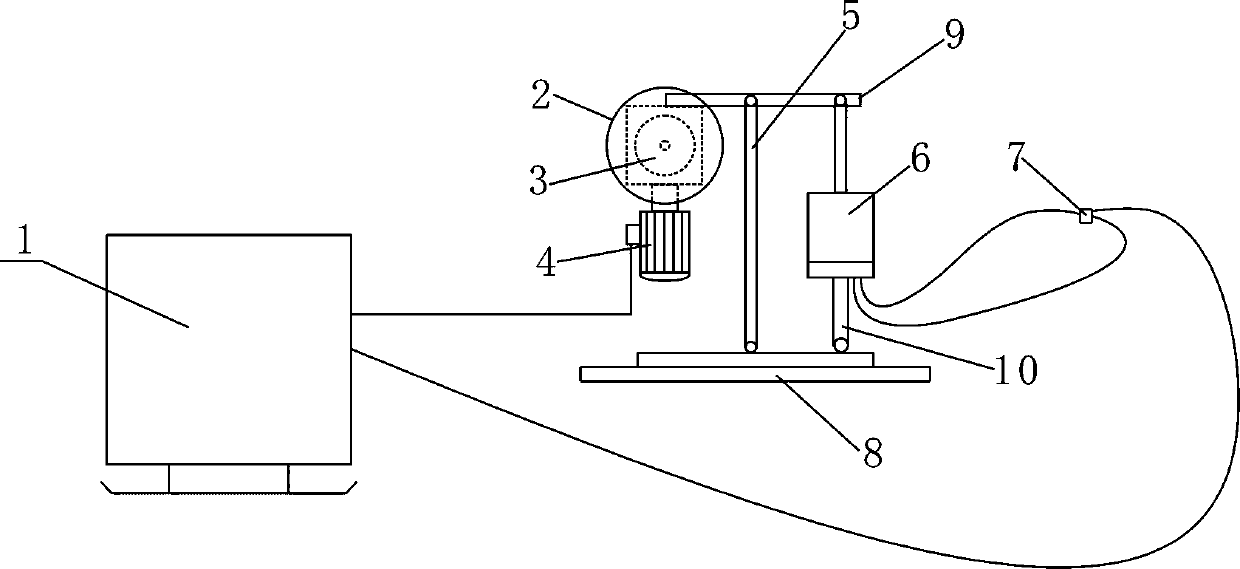

[0008] Now refer to the attached figure 1 , described as follows in conjunction with the embodiment: A friction type automatic cranking device according to the present invention includes a programmable control box 1, an electromagnetic reversing valve 7, a base 8 and a bracket 5, and it is characterized in that the bracket 5 Hinged on the base 8, the top of the support 5 is hinged with a connecting rod 9, behind the support 5, a support rod 10 is hinged on the base 8, and the top of the support rod 10 is connected with a telescopic cylinder 6, The upper end of the telescopic rod of the telescopic cylinder 6 is hinged with the tail end of the connecting rod 9, and the telescopic cylinder 6 is electrically connected to the electromagnetic reversing valve 7 through a pipeline, and the electromagnetic reversing valve 7 is connected to the programmable control box 1 is electrically connected, a planetary gear reducer 3 is arranged under the front end of the connecting rod 9, a fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com