Fire hose inner and outer tube casing machine

A fire hose and outer tube technology, which is applied in the field of fire hose inner and outer tube fitting machines, can solve the problems of complicated manual fitting technology, high labor intensity for operators, and high production costs, and achieve reliable mutual bonding, Uniform motor traction and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

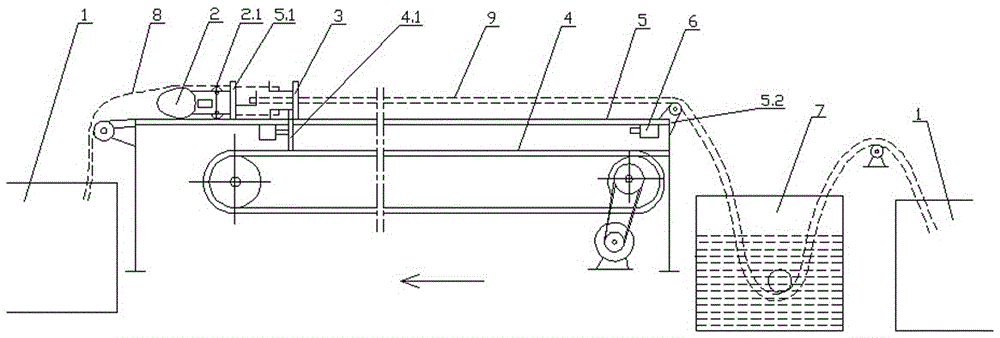

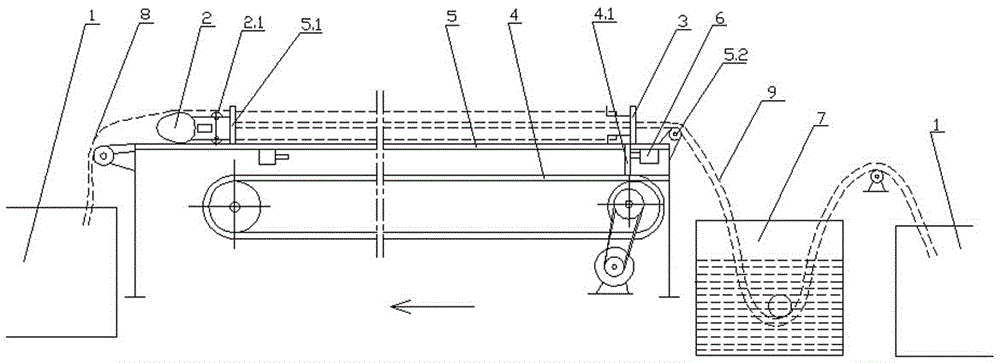

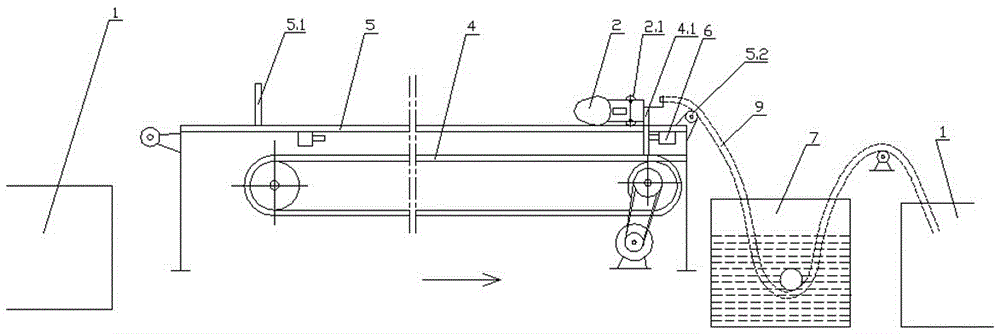

[0018] figure 1 The shown fire hose inner and outer layer pipe fitting machine includes a material box 1, a guide 2, an expansion hook 3, a belt transmission mechanism 4, a workbench 5, a limit switch 6 and a glue pool 7. The machine is based on a flat elongated workbench 5 as the main structure, and a material box 1 is respectively placed at both ends of the workbench 5. Box 1 places the rubber hose 9 to be fitted. A glue pool 7 is provided between the material box 1 for storing the rubber hose 9 and the workbench 5. This structure enables the outer wall of the rubber hose 9 to be fitted to pass through the glue pool 7 to obtain uniform glue coating. The guide 2 is a special device for pulling and positioning the rubber hose 9. Its shape is tadpole-shaped, and the egg-shaped head is convenient for guiding. The guider 2 runs through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com