Light source output control method and system, and laser projection device

An output control and light source technology, applied in optics, instruments, projection devices, etc., can solve the problems of reduced monochromatic light brightness and high difficulty in assembly process, and achieve the effect of eliminating color mixing and ensuring color brightness and timing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

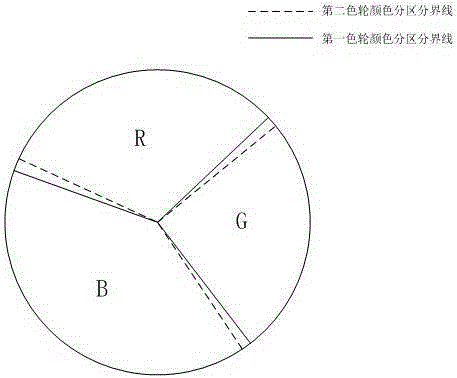

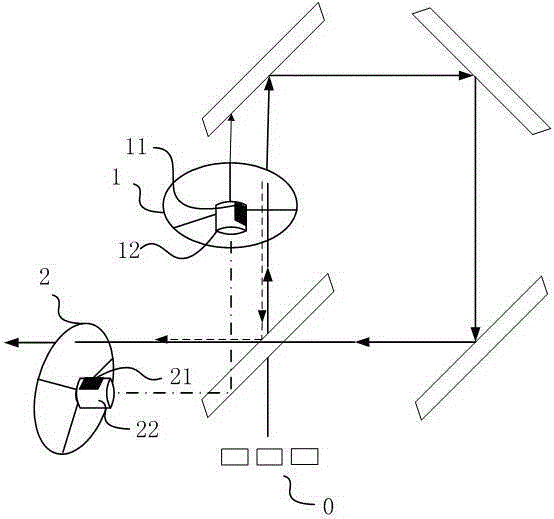

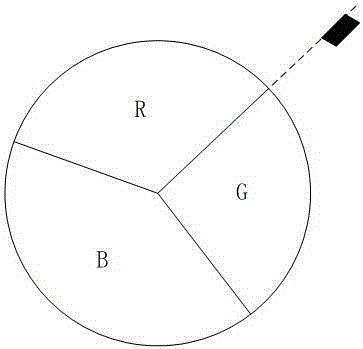

[0041] The present invention aims to provide a light source output control method, which is applied to a light source with a non-coaxial design of two-color wheels. The light source as figure 2 As shown, including laser 0, first color wheel 1 and second color wheel 2. Wherein, the laser 0 emits laser light, irradiates the first color wheel 1 to generate fluorescence, and the laser light and the fluorescence emit through the corresponding color zones on the second color wheel 2 respectively. The first color wheel 1 and the second color wheel 2 have the same color division, so that laser light and fluorescent light can pass through the two color wheels corresponding to the same color division at the same time.

[0042] An example of the non-coaxial position and structure relationship of the two-color wheel can be as follows figure 2 As shown, the first color wheel 1 and the second color wheel 2 are respectively connected with driving motor shafts 12 and 22 to drive the wheel...

Embodiment 2

[0056] Embodiment 2 of the present invention is an improvement and refinement on the basis of Embodiment 1.

[0057] Wherein, for step S1: according to the acquired first group of sensing signals of the first synchronization mark and the second synchronization mark, synchronizing the first color wheel and the second color wheel specifically includes: Figure 6 Shown:

[0058] Step S11: Within one rotation period, respectively acquire sensing signals corresponding to the first synchronization mark and the second synchronization mark, which are recorded as the first group of sensing pulse signals.

[0059] In this embodiment of the method, the synchronous mark can be a black film or black tape or a carbonized mark. Black has a light-absorbing effect, so when the signal sent by the sensor encounters the above-mentioned black mark on the surface of the rotating shaft during the rotation of the driving motor shaft is absorbed, and the non-marked part on the side of the motor shaft...

Embodiment 3

[0082] Based on the above light source output control method, the embodiment of the present invention also proposes a light source output control system, such as Figure 13 As shown, a first color wheel 21 is included, and the first color wheel 21 includes a first synchronization mark (not shown in the figure); a second color wheel 22, and the second color wheel 22 includes a second synchronization mark (not shown in the figure). ), where the first synchronization mark corresponds to the position of the second synchronization mark on the corresponding color wheel, the system also includes a first sensor 23 , a second sensor 24 , a third sensor 25 and a control unit 26 .

[0083] Wherein, the first sensor 23 is used to detect and obtain the sensing signal of the first synchronization mark of the first color wheel, which is an infrared sensor or a light sensor; the second sensor 24 is used to detect and obtain the second synchronization of the second color wheel The sensing sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com