Debris flow moving and accumulating process simulation experiment system

A technology for simulating experiments and debris flow. It is used in fluid dynamics tests, testing of machine/structural components, instruments, etc. It can solve the problems of low occurrence frequency of debris flow, large differences in debris flow characteristics, and difficulty in tracking debris flow. Difficulty and Dangerous Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

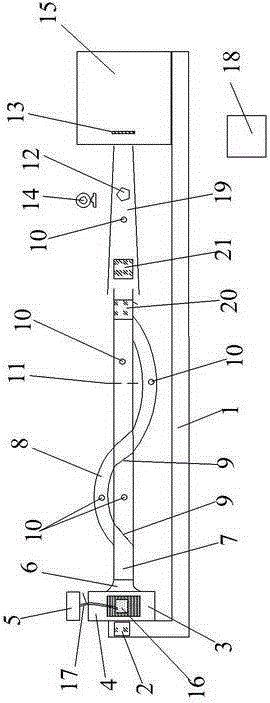

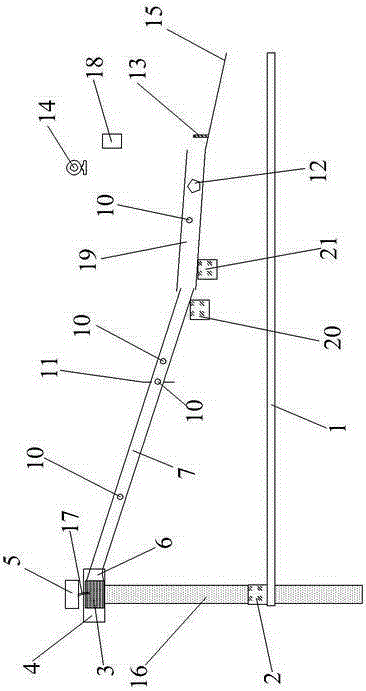

[0011] see figure 1 and figure 2 As shown, the present invention includes a conveyor belt 1, a first elevator 2, a second elevator 20, a third elevator 21, a stirring box 3, a working platform 4, a water tank 5, a connecting tank 6, a first direct-current channel 7, a second direct-current channel Groove 19, curved flow groove 8, flow groove valve 9, pore pressure test device 10, bayonet 11, flow rate and flow test device 12, impact force test device 13, high-speed camera 14, accumulation area 15, column foundation 16, pumping device 17 and receiving host 18; the working platform 4 is arranged on the column foundation 16 upper end, the mixing box 3 is placed on the working platform 4, the first elevator 2 is arranged beside the column foundation 16, and the upper end of the conveyor belt 1 is arranged on the first elevator 2 and is positioned at the stirring The upper part of the tank 3; the water tank 5 communicates with the stirring tank 3 through the pumping device 17; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com