A boiler economizer

A technology for economizers and boilers, applied in feed water heaters, preheating, steam generation, etc., can solve the problems of difficult layout, increase the overall height of economizers, etc., to avoid deformation of tube bundles, facilitate installation and maintenance, and improve tube bundles Effect of Clamp Stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

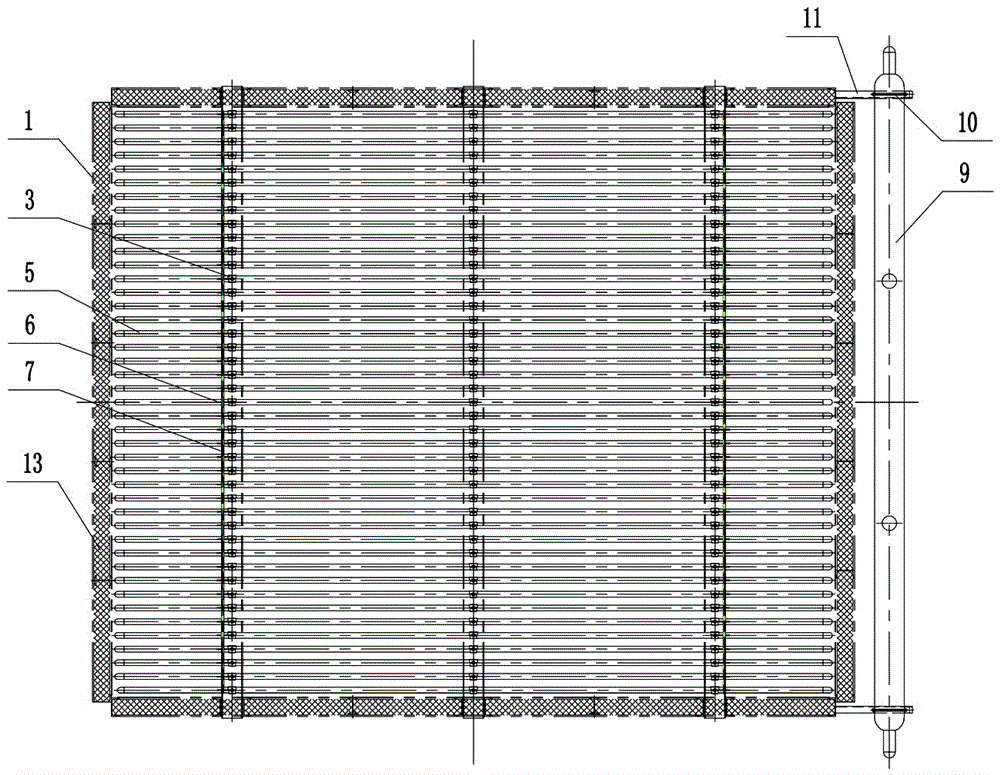

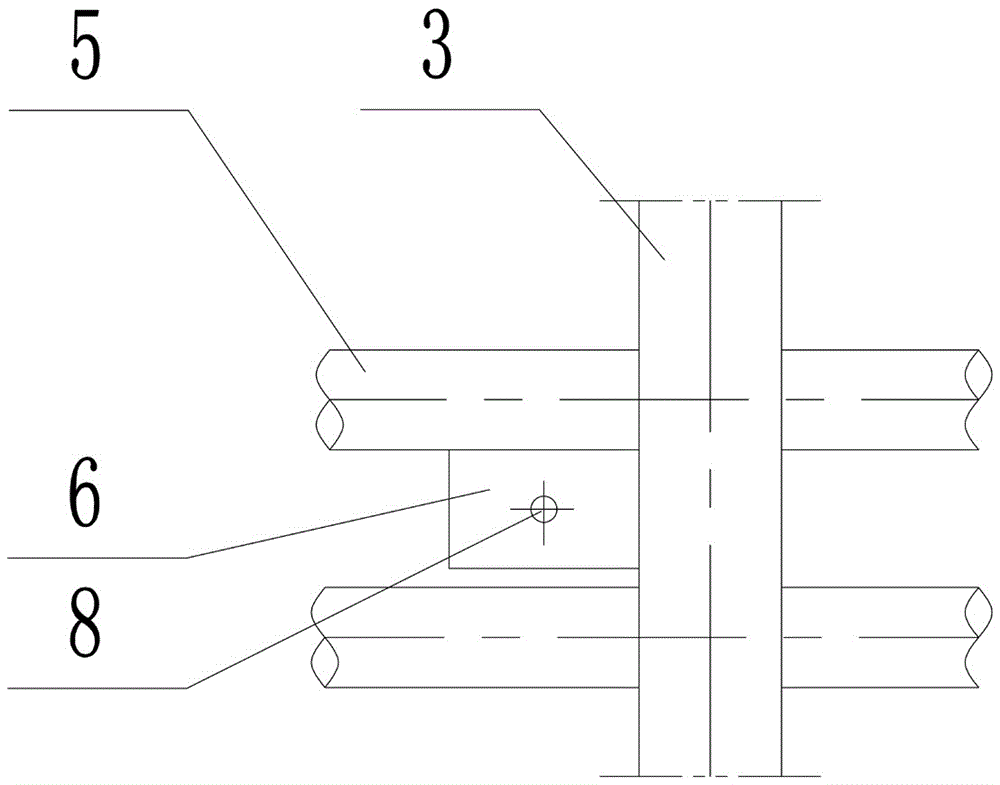

[0029] A boiler economizer, comprising a guard plate 1, a support beam 2, a pipe clamp 3 and a serpentine pipe system 4. The guard plate 1 encloses and forms a flue, and the serpentine pipe system 4 is installed in the flue. The support beam 2 is erected horizontally on the guard plate 1 . The pipe clamp 3 is vertically fixed on the support beam 2 . The serpentine pipe system 4 includes a group of serpentine pipe bundles 5 arranged at equal heights and arranged at intervals. The serpentine tube bundle 5 is fixed by a tube clamp 3 . The serpentine pipe system 4 is equipped with a positioning plate 6 . The positioning plate 6 is arranged next to the pipe clamp 3 .

[0030] Preferably, the positioning plates 6 are welded to the serpentine tube bundle 5 at the same height, and the positioning plates 6 are arranged in a horizontal row. More preferably, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com