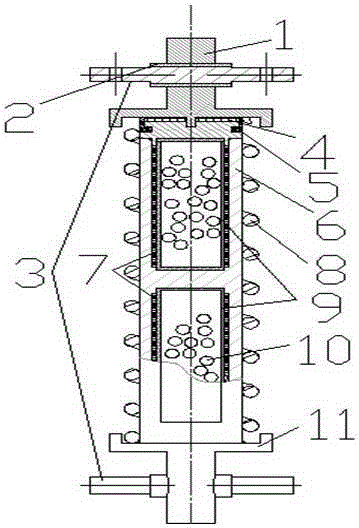

Semi-active electromagnetic particle damping shock absorber for railway vehicle

A semi-active, rail vehicle technology, applied in the field of rail vehicles, can solve the problems of high manufacturing precision, inability to adjust, and high cost, and achieve the effects of reducing stiffness, increasing stability, and improving adaptability to harsh environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

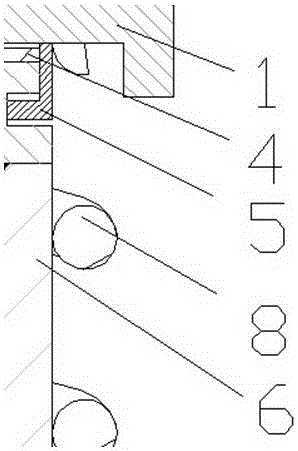

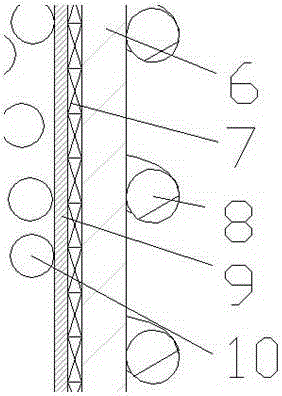

[0026] Embodiment 1: A semi-active particle damping shock absorber for a rail vehicle, such as figure 1 , figure 2 with image 3 As shown, it includes a shell 6, the shell 6 is made of a cylindrical composite damping steel plate, and the shell 6 is divided into upper and lower cavities; the cavity is separated by a wear-resistant metal interlayer 9, and the wear-resistant metal interlayer 9 is installed In the cavity of the shell 6, there is an interference fit between the two; the electromagnetic coil 7 is embedded in the groove on the wear-resistant metal interlayer 9 and the inner wall of the shell 6; the volume ratio of the wear-resistant metal interlayer 9 is 50-70 % of vibration damping particles 10, the selection of its parameters should be determined according to the actual vehicle conditions, and the vehicle vibration environment is relatively severe and complex, and at the same time, viscoelastic material particles or non-metallic particles can be added to adopt it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com