A six-point contact double-row ball roller bearing and its groove processing method and device

A roller bearing and point contact technology, which is applied in the direction of ball bearings, shafts and bearings, bearing components, etc., can solve the problems of fast wear of the inner ring, failure of the process to meet the requirements, and improvement of the process, so as to improve the service life and design the structure Simple and ingenious, the effect of reducing the amount of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

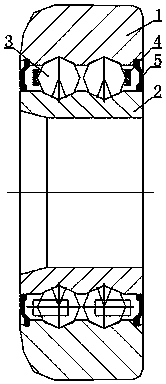

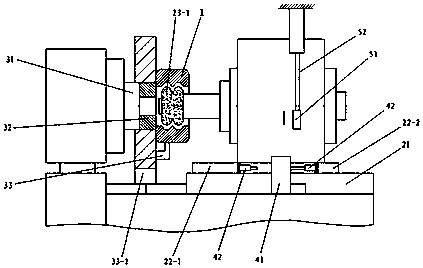

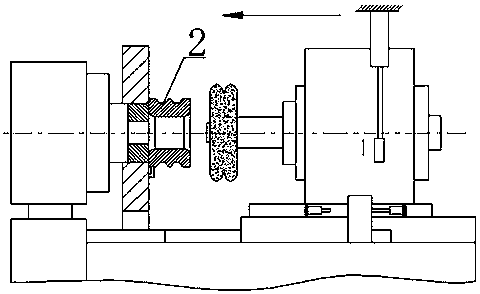

[0018] Refer to attached figure 1 , a six-point contact double row ball roller bearing, which includes an outer ring 1, an inner ring 2, steel balls 3, and a cage 4. The inner ring 2 is installed in the outer ring 1, and the outer side of the inner ring 2 and the inner side of the outer ring 1 are respectively It is designed with double-row grooves with the same spacing. The double-row groove inside the outer ring 1 is a spherical curved surface ring groove, and the double-row groove designed outside the inner ring 2 is a peach shape composed of two non-concentric hyperboloids. Groove ring groove, the steel ball 3 is installed between the outer ring and the inner ring through the cage 4. Seal retaining rings 5 are installed at both ends between the inner ring and the outer ring.

[0019] The steel ball 3 has one point contact with the spherical surface ring groove of the outer ring 1, the steel ball 3 has two contact points with the peach-shaped groove ring groove on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com