Combustion Timing Control Method of HCCI Engine Based on Linear Model and Sliding Mode Controller

A combustion timing and linear model technology, applied in engine control, machine/engine, electrical control, etc., can solve problems such as few controllers, complex linearization of discrete nonlinear models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with accompanying drawing.

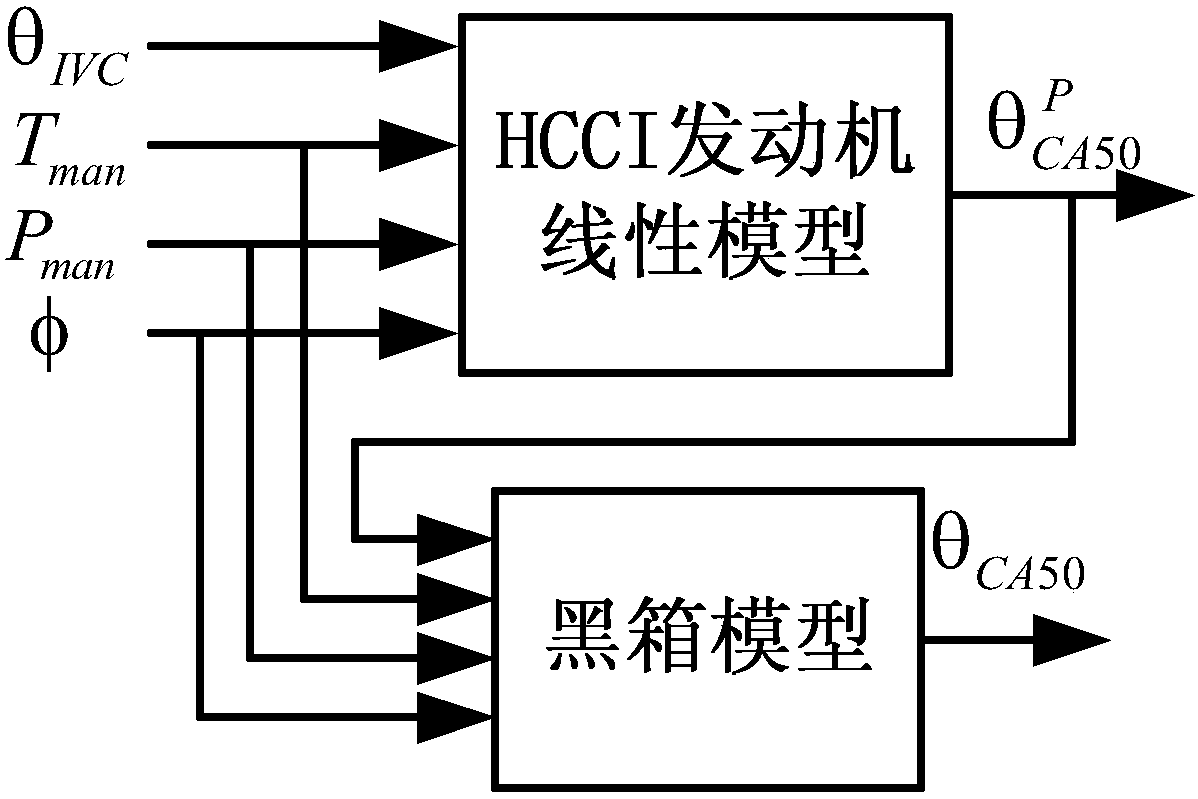

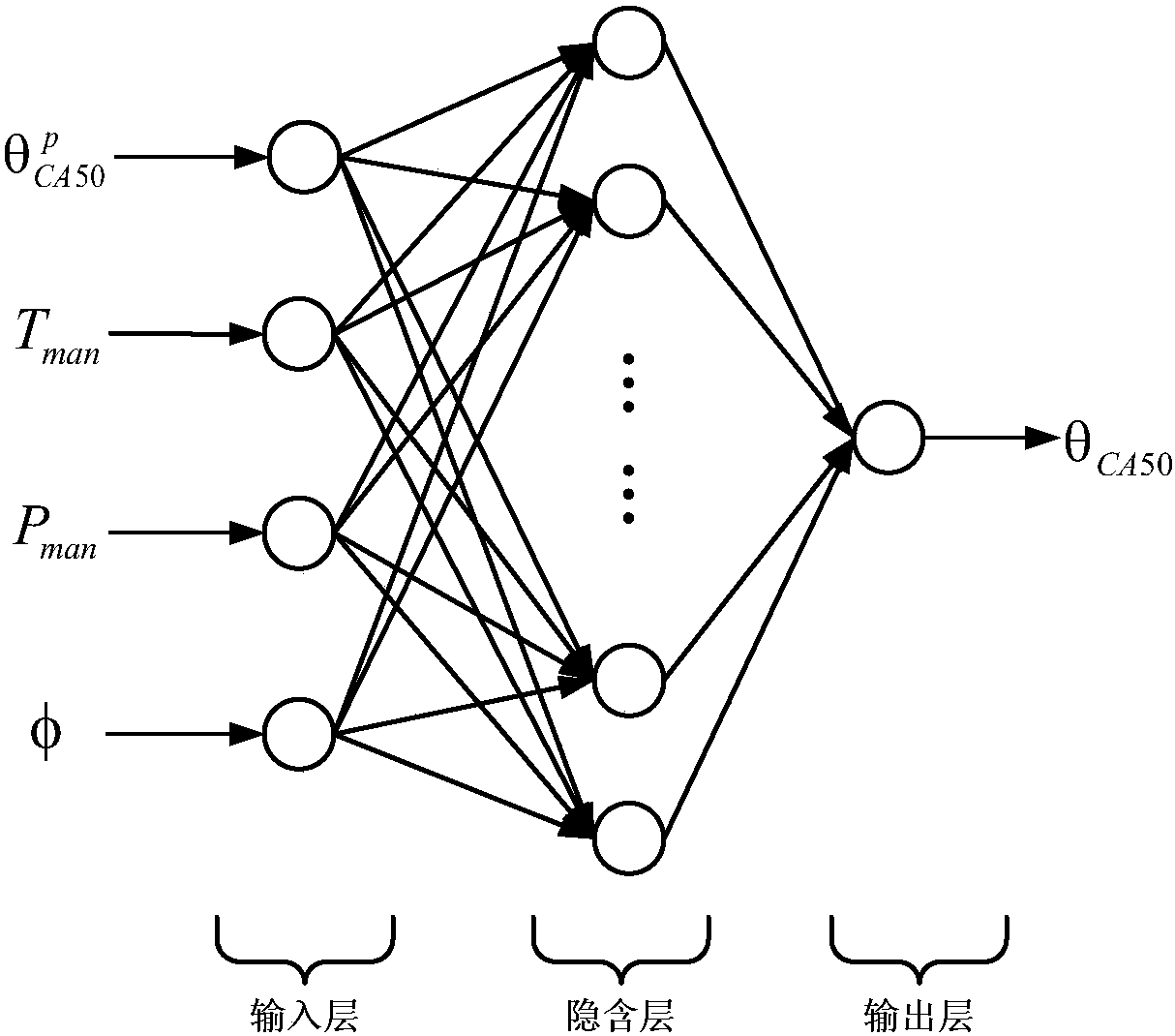

[0064] The invention discloses a nonlinear discrete system linearization method, and designs a discrete sliding mode controller based on an exponential approach rate for discrete linear state equations. Due to the particularity of the discrete system, the state of each cycle of the system can be obtained, so the multiple linear regression method is selected to fit each parameter of the state equation, so as to obtain the state equation of the linear discrete system. Because the linearized equation has certain errors compared with the actual engine, the black box model is designed by using BP neural network to correct the error of the linearized model. Based on this model, a discrete sliding mode controller with Kalman filter is designed. The invention guarantees the accuracy of the linear model and the accuracy of the combustion timing to track the ideal input.

[0065] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com