Light fire-resistant and anti-seismic partition wall and method for manufacturing same

A fire-resistant and light-weight technology, applied in the field of prefabricated assembly partition walls, can solve problems such as poor sound insulation performance, heavy weight, and squeezed space, and achieve good sound insulation and heat insulation capabilities, fast construction speed, and convenient connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

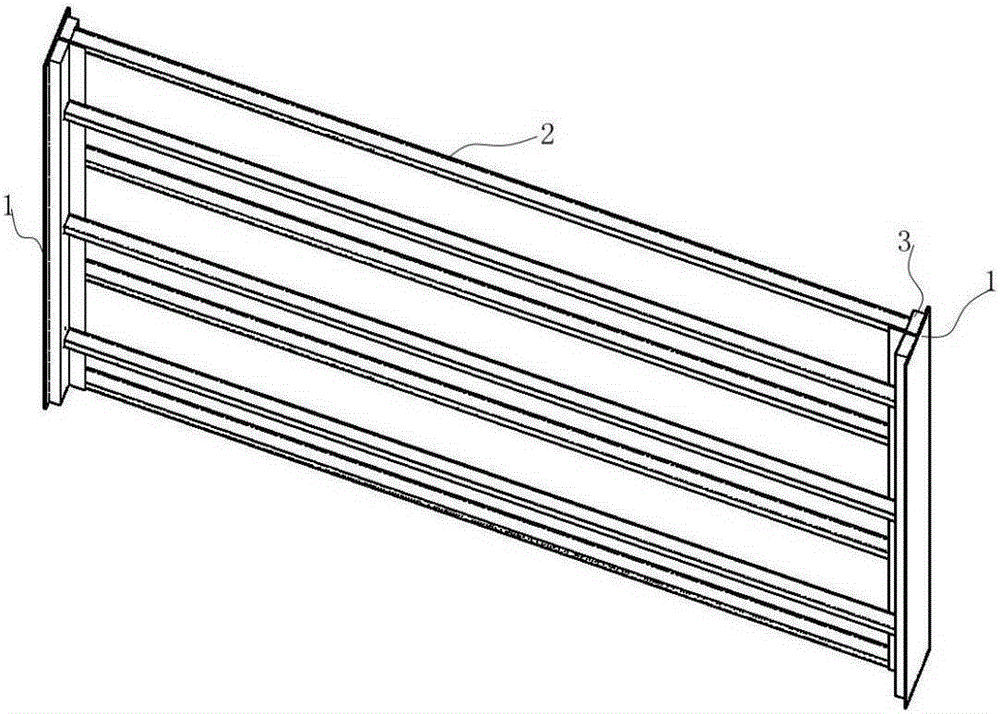

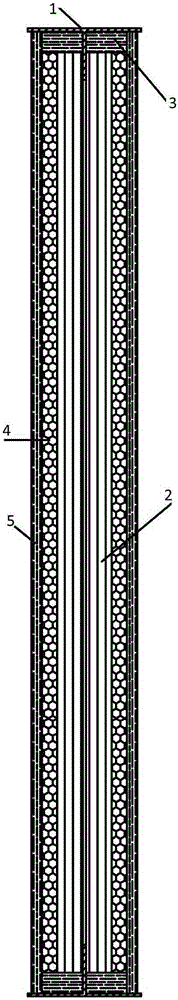

[0022] Such as figure 1 with figure 2 As shown, the lightweight refractory and earthquake-resistant partition wall of the present invention mainly includes: T-shaped steel, square wood, rectangular steel pipe, birch board and glass fiber. Wherein, the two sides of each partition wall are T-shaped steels, the webs of the T-shaped steels 1 are arranged facing inward, and the flange plates are parallel to each other. The two ends of the rectangular steel pipe 2 are respectively welded on the web of the adjacent T-shaped steel, figure 1 In the shown embodiment, in the length direction of the T-shaped steel web, the rectangular steel pipes are arranged alternately along both sides of the web. Continue to see figure 1 In the upper left corner and the lower right, the square wood 3 is fixedly arranged on the inner side of the T-shaped steel flange plate.

[0023] go to figure 2 , it can be seen from the section that the birch board 5 and the glass fiber 4 are arranged on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com