Ag-doped Mg2Si-based thermoelectric thin film and preparing method thereof

A technology of thermoelectric thin film and power supply, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of low efficiency, cumbersome process, poor controllability, etc., achieve cost reduction, simplify preparation process, improve The effect of thermoelectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Use acetone and alcohol to ultrasonically clean the glass slides for 15 minutes respectively;

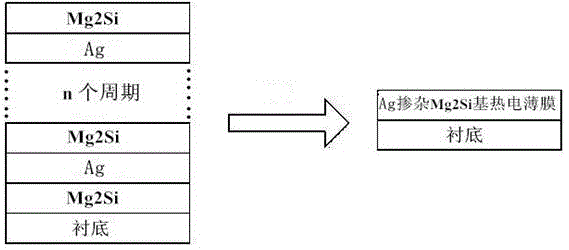

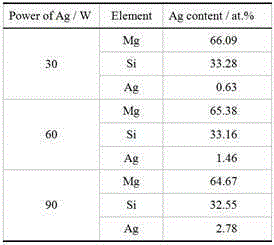

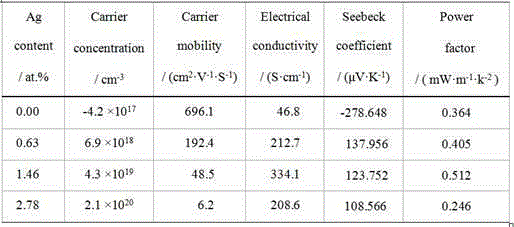

[0026] 2) The double-target circular sputtering is carried out by the magnetron sputtering deposition method, in which, one target position puts Mg 2 For the Si target, the power supply is radio frequency power; the other target is placed on the Ag single target, and the power supply is DC power; the vacuum is pumped to 6.5×10 -4 Below Pa, high-purity Ar gas with a flow rate of 30sccm is used as the working gas, and the working pressure is 0.5Pa; firstly, a layer of Mg is plated on the substrate 2 Si, followed by a thin layer of Ag, followed by a layer of Mg 2 Si; Mg 2 Si target RF sputtering power is 120W, Ag target DC sputtering power is 30W; cycle is 12 times, Ag and Mg 2 The sputtering time ratio of Si is 1:10, and the total sputtering time is 1h;

[0027] 3) After the sputtering is completed, turn off the sputtering source, and the background vacuum is better than...

Embodiment 2

[0029] 1) Use acetone and alcohol to ultrasonically clean the glass slides for 15 minutes respectively;

[0030] 2) The double-target circular sputtering is carried out by the magnetron sputtering deposition method, in which, one target position puts Mg 2 For the Si target, the power supply is radio frequency power; the other target is placed on the Ag single target, and the power supply is DC power; the vacuum is pumped to 6.5×10 -4Below Pa, high-purity Ar gas with a flow rate of 30sccm is used as the working gas, and the working pressure is 5.0Pa; firstly, a layer of Mg is plated on the substrate 2 Si, followed by a thin layer of Ag, followed by a layer of Mg 2 Si; Mg 2 Si target RF sputtering power is 120W, Ag target DC sputtering power is 60W; cycle is 24 times, Ag and Mg 2 The sputtering time ratio of Si is 1:60, and the total sputtering time is 1.5h;

[0031] 3) After the sputtering is completed, turn off the sputtering source, and the background vacuum is better tha...

Embodiment 3

[0033] 1) Use acetone and alcohol to ultrasonically clean the glass slides for 15 minutes respectively;

[0034] 2) The magnetron sputtering deposition method is used to carry out double-target cyclic sputtering, in which, one target is placed on Mg 2 For the Si target, the power supply is radio frequency power; the other target is placed on the Ag single target, and the power supply is DC power; the vacuum is pumped to 6.5×10 -4 Below Pa, high-purity Ar gas with a flow rate of 30sccm is used as the working gas, and the working pressure is 0.1Pa; firstly, a layer of Mg is plated on the substrate 2 Si, followed by a thin layer of Ag, followed by a layer of Mg 2 Si; Mg 2 The RF sputtering power of the Si target is 120W, and the DC sputtering power of the Ag target is 90W; the cycle is 1 time, Ag and Mg 2 The sputtering time ratio of Si is 1:4, and the total sputtering time is 1h;

[0035] 3) After the sputtering is completed, turn off the sputtering source, and the backgrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com