Gasoline-resistant powder paint

A powder coating, gasoline-resistant technology, applied in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of obviousness, loss of gloss, coating film drop, etc., and achieve the effect of avoiding loss of gloss and good resistance to gasoline erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

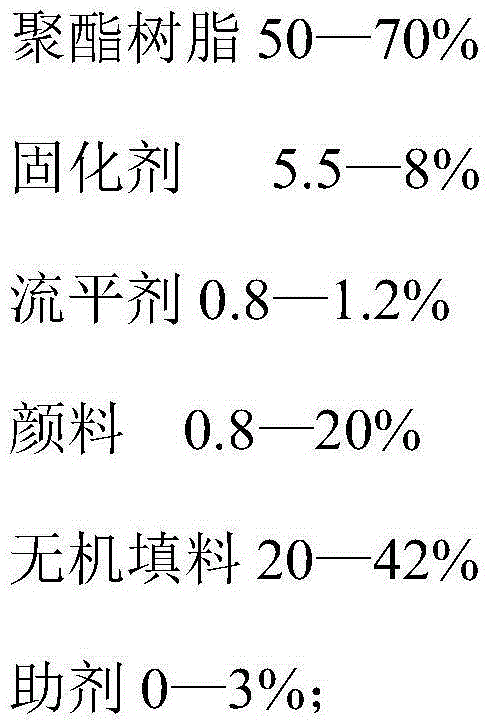

[0026] A gasoline-resistant powder coating, comprising the following components in mass percentages:

[0027]

[0028]

[0029] The polyester resin is a carboxyl-terminated saturated polyester resin;

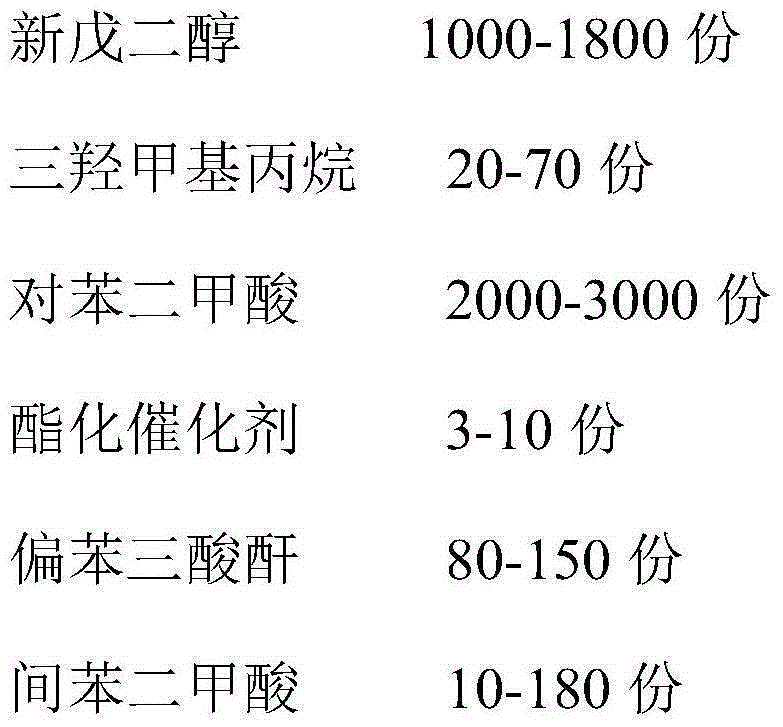

[0030] Described polyester resin comprises following weight part raw material:

[0031]

[0032] The esterification catalyst is monobutyltin oxide.

[0033] The preparation method of described polyester resin, comprises the following steps:

[0034] (1) Put 1,500 parts by mass of neopentyl glycol and 50 parts of trimethylolpropane into a reaction kettle, heat to 120° C. to melt, stir and mix;

[0035] (2) Add 2400 parts of terephthalic acid and 5 parts of esterification catalyst; heat to 240°C to maintain the reaction until the reactant is clear, take a sample, and the acid value of the test sample is 10.5 mgKOH / g;

[0036] (3) Cool down to 180°C, then add 100 parts of trimellitic anhydride and 540 parts of isophthalic acid, raise the temperature to 220°C and maintai...

Embodiment 2

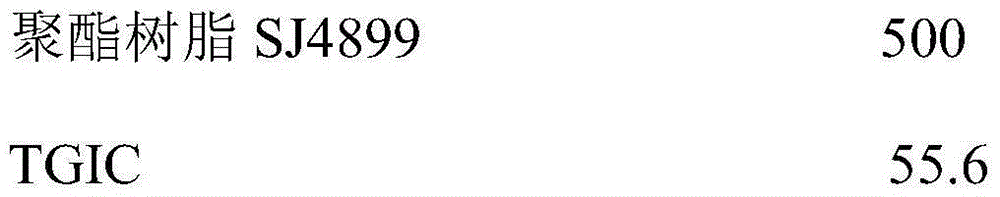

[0039] A gasoline-resistant powder coating, comprising the following components in mass percentages:

[0040]

[0041] Described polyester resin comprises following weight part raw material:

[0042]

[0043] The esterification catalyst is monobutyltin oxide.

[0044] The preparation method of described polyester resin is:

[0045] (1) Put 1,800 parts by mass of neopentyl glycol and 70 parts of trimethylolpropane into the reaction kettle, heat to 130°C to melt, stir and mix;

[0046] (2) Add 3000 parts of terephthalic acid and 9 parts of esterification catalyst; heat to 220-240 ° C to maintain the reaction until the reactant is clear, take a sample, and the acid value of the test sample is 10.5 mgKOH / g;

[0047] (3) Cool down to 200°C, then add 140 parts of trimellitic anhydride and 180 parts of isophthalic acid, raise the temperature to 220°C and maintain until the reactants are clear, and the acid value is 63.6mgKOH / g by sampling;

[0048] (4) Vacuumize for 3.5 hour...

Embodiment 3

[0050] A gasoline-resistant powder coating, comprising the following components in mass percentages:

[0051]

[0052] Described polyester resin comprises following weight part raw material:

[0053]

[0054]

[0055] The esterification catalyst is monobutyltin oxide.

[0056] The preparation method of described polyester resin is:

[0057] (1) Put 1,400 parts by mass of neopentyl glycol and 50 parts of trimethylolpropane into a reaction kettle, heat to 100°C to melt, stir and mix;

[0058] (2) Add 2300 parts of terephthalic acid and 6 parts of esterification catalyst; heat to 220-240 ° C to maintain the reaction until the reactant is clear, take a sample, and the acid value of the test sample is 10.5 mgKOH / g;

[0059] (3) Cool down to 180°C, then add 140 parts of trimellitic anhydride and 120 parts of isophthalic acid, raise the temperature to 220°C and maintain until the reactants are clear, and the acid value is 63.6mgKOH / g by sampling;

[0060] (4) Vacuumize fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com