High-strength high-performance manufactured sand concrete with no mineral admixture

A machine-made sand, high-strength technology, applied in the field of concrete formulation, can solve the problems of poor viscosity of mixtures with the ability of hydrates to bind chloride ions, unstable performance of mineral admixtures, and inability to obtain materials on site, so as to solve the shortage of river sand. , Increase durability, overcome the effect of unstable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment D1-D7

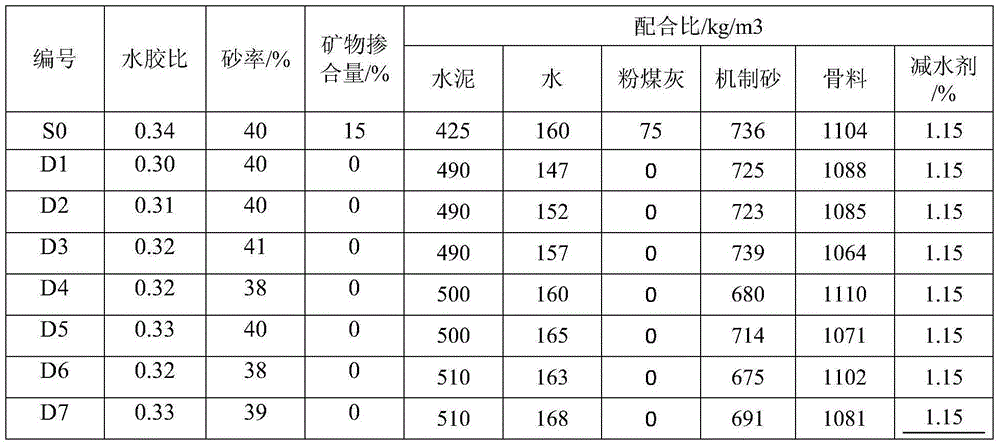

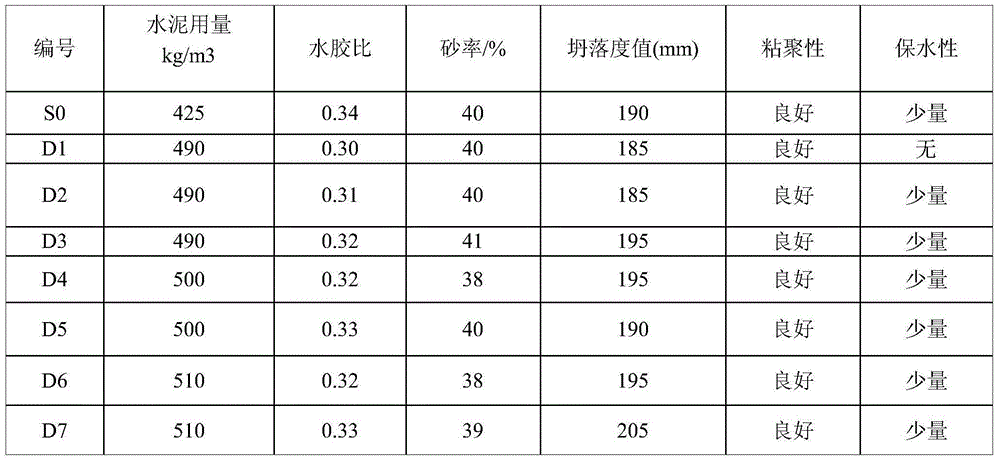

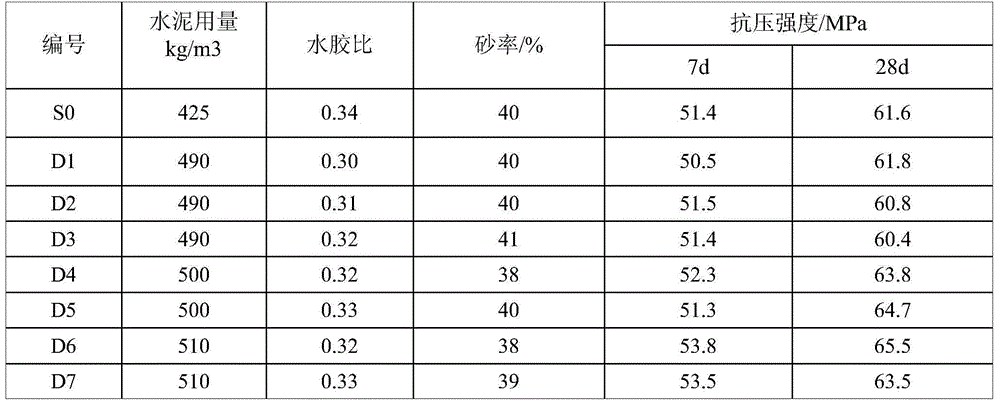

[0013] The specific parameters are shown in Table 1. The percentages of sand rate, mineral blending amount and water reducer in the table are all percentages by weight.

[0014] Among them: the aggregate and the machine-made sand are both made from the parent rock, the compressive strength of the parent rock is above 80MPa, and the aggregate is obtained when the parent rock is ground to a stone with a particle size of 5-25mm, that is to say, the aggregate The particle size is 5-25mm, of which: the ratio of grade I aggregate to grade II aggregate is 6.7:3.3, the particle size of grade I aggregate is 15-25mm, and the particle size of grade II aggregate is 5-15mm

[0015] The weight content of stone powder in the machine-made sand is 5-10%, and the weight content of mud is less than 0.5%. When preparing concrete, control the ambient temperature at 8-15°C during pouring, pay attention to moisturizing, heat preservation and maintenance, and control the temperature difference betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com