Process and device for preparing sulphur through coked sulfur paste

A coking sulfur and process technology, applied in inorganic chemistry, sulfur compounds, chemical instruments and methods, etc., can solve problems such as large human injury and poor sulfur separation effect, achieve complete separation of impurities, reduce heating and melting time, and improve purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

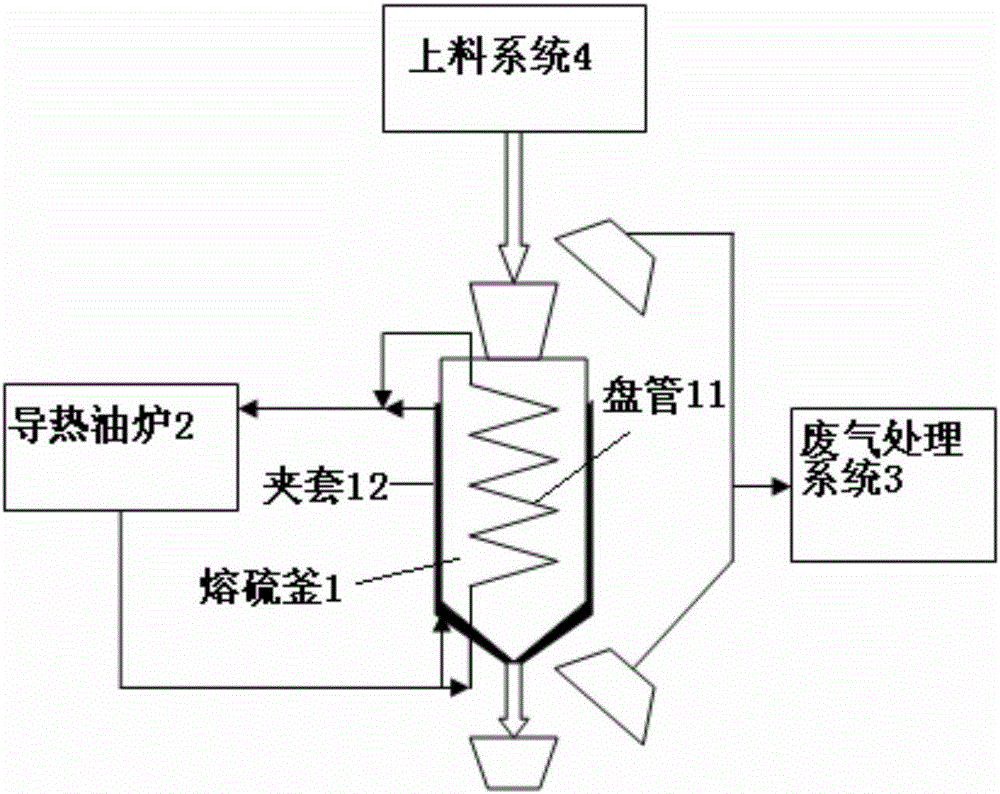

[0070] Open the inlet valve of the sulfur melting kettle, transport the coking sulfur paste from the sulfur paste pool to the hopper of the sulfur melting kettle with a driving grab bucket, and flow into the sulfur melting kettle by gravity. When the sulfur paste in the melting sulfur kettle reaches 70-80% of the volume of the sulfur melting kettle, stop feeding, and close the feed valve of the sulfur melting kettle.

[0071] Open the inlet and outlet valves of the jacket and coil of the sulfur melting kettle, turn on the heat transfer oil furnace, and heat the coking sulfur paste in the sulfur melting kettle at 240°C, and the internal pressure of the sulfur melting kettle is 0.55MPa. When the temperature at the top of the sulfur melting kettle reaches 145±5°C, sulfur release begins.

[0072]Place the material receiving box at the lower part of the discharge pipe, open the valve of the tail gas collecting cover, slowly and uniformly put the liquid sulfur into the material rece...

Embodiment 2

[0076] Open the inlet valve of the sulfur melting kettle, transport the sulfur paste from the sulfur paste pool to the hopper of the sulfur melting kettle with a driving grab, and flow into the sulfur melting kettle by gravity. When the sulfur paste in the melting sulfur kettle reaches 70-80% of the volume of the sulfur melting kettle, stop feeding, and close the feed valve of the sulfur melting kettle.

[0077] Open the inlet and outlet valves of the jacket and coil of the sulfur melting kettle, turn on the heat transfer oil furnace, and heat the coking sulfur paste in the sulfur melting kettle at 200°C, and the internal pressure of the sulfur melting kettle is 0.55MPa. When the temperature at the top of the sulfur melting kettle reaches 145±5°C, sulfur release begins.

[0078] Place the material receiving box at the lower part of the discharge pipe, open the valve of the tail gas collecting cover, slowly and uniformly put the liquid sulfur into the material receiving box, co...

Embodiment 3

[0082] Open the inlet valve of the sulfur melting kettle, transport the sulfur paste from the sulfur paste pool to the hopper of the sulfur melting kettle with a driving grab, and flow into the sulfur melting kettle by gravity. When the sulfur paste in the melting sulfur kettle reaches 70-80% of the volume of the sulfur melting kettle, stop feeding, and close the feed valve of the sulfur melting kettle.

[0083] Open the inlet and outlet valves of the jacket and coil of the sulfur melting kettle, turn on the heat transfer oil furnace, and heat the coking sulfur paste in the sulfur melting kettle at 150°C, and the internal pressure of the sulfur melting kettle is 0.55MPa. When the temperature at the top of the sulfur melting kettle reaches 145±5°C, sulfur release begins.

[0084] Place the material receiving box at the lower part of the discharge pipe, open the valve of the tail gas collecting cover, slowly and uniformly put the liquid sulfur into the material receiving box, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com