An automatic leveling device suitable for industrial vehicles

An automatic leveling, industrial vehicle technology, applied in the direction of lifting devices, etc., can solve the problems of reduced work efficiency, difficulty, unsafe factors, etc., to achieve the effect of protecting parts, uniform force, and tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

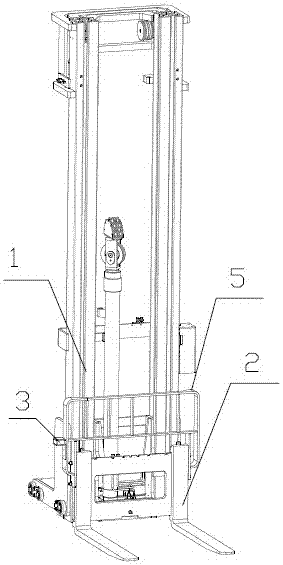

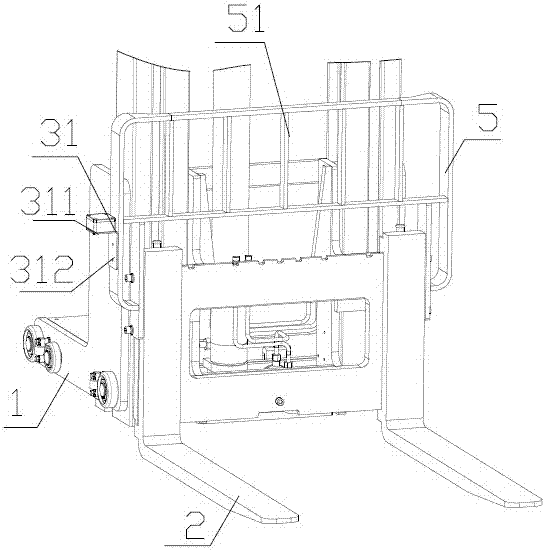

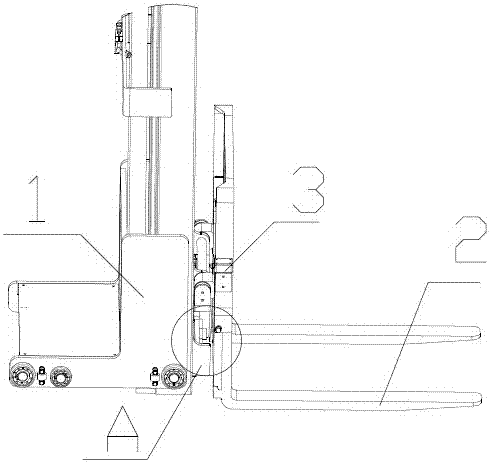

[0037] Example 1, such as figure 1 , figure 2 , image 3 and Figure 4Shown: an automatic leveling device suitable for industrial vehicles, including a car body 1, a fork assembly 2 installed on the car body 1, this kind of automatic leveling device suitable for industrial vehicles also includes a The sensing device 3 for the angle between the fork assembly 2 and the horizontal plane, the angle adjustment device 4 for adjusting the angle between the fork assembly 2 and the horizontal plane, and the limit device 6 for limiting the inclination angle between the fork assembly 2 and the horizontal plane, the fork The component 2 is hinged with the car body 1, the angle adjustment device 4 includes a PLC controller 41 and a push-out device 42, the fork assembly 2 includes a fork body for lifting goods, and the fork assembly 2 is provided with a sensing device 3 for sensing The device 3 can sense the extension direction of the fork body and the inclination angle of the horizonta...

Embodiment 2

[0042] Embodiment 2: The difference from Embodiment 1 is the difference of the sensing device 3, which includes an infrared emitting device and an infrared receiving device. When the ground of the industrial environment used by the forklift has good reflectivity, the infrared emitting device and the infrared receiving device can be used. The emitted infrared rays are reflected by the ground and captured by the infrared receiving device. According to the specific position of the capture, the inclination angle can be judged. However, the infrared device cannot capture the angle with the horizontal plane, only the angle with the ground, which is only suitable for flat industrial environments, and is not suitable for working environments with uphill and downhill slopes.

Embodiment 3

[0043] Embodiment 3: The difference from Embodiment 1 is the difference between the limit device 6 and the push-out device 42. The push-out device 42 is a plurality of hydraulic telescopic rods. The device 6 is a bump that is arranged on the vehicle body 1 and interferes with the fork assembly 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com