Automatic leveling device and method for three-coordinate measurement of finished vehicle

A three-coordinate measurement and automatic leveling technology, applied in measuring devices, instruments, etc., can solve the problems of long time and low efficiency, and achieve the effect of saving labor costs and high leveling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

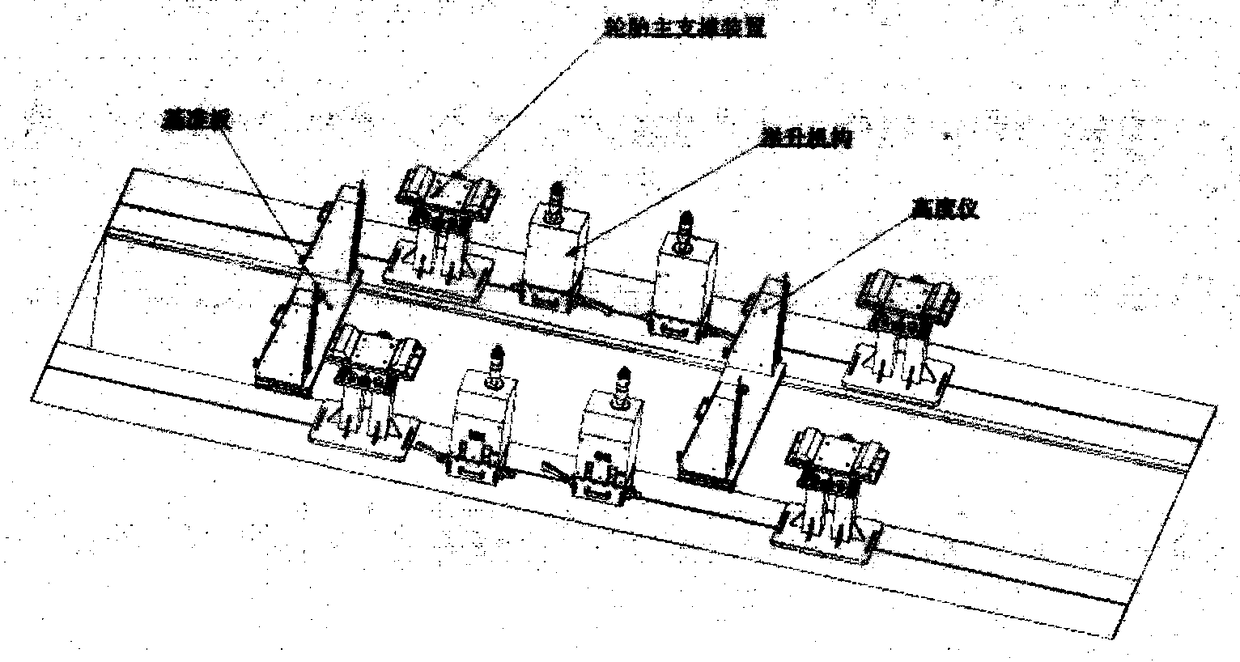

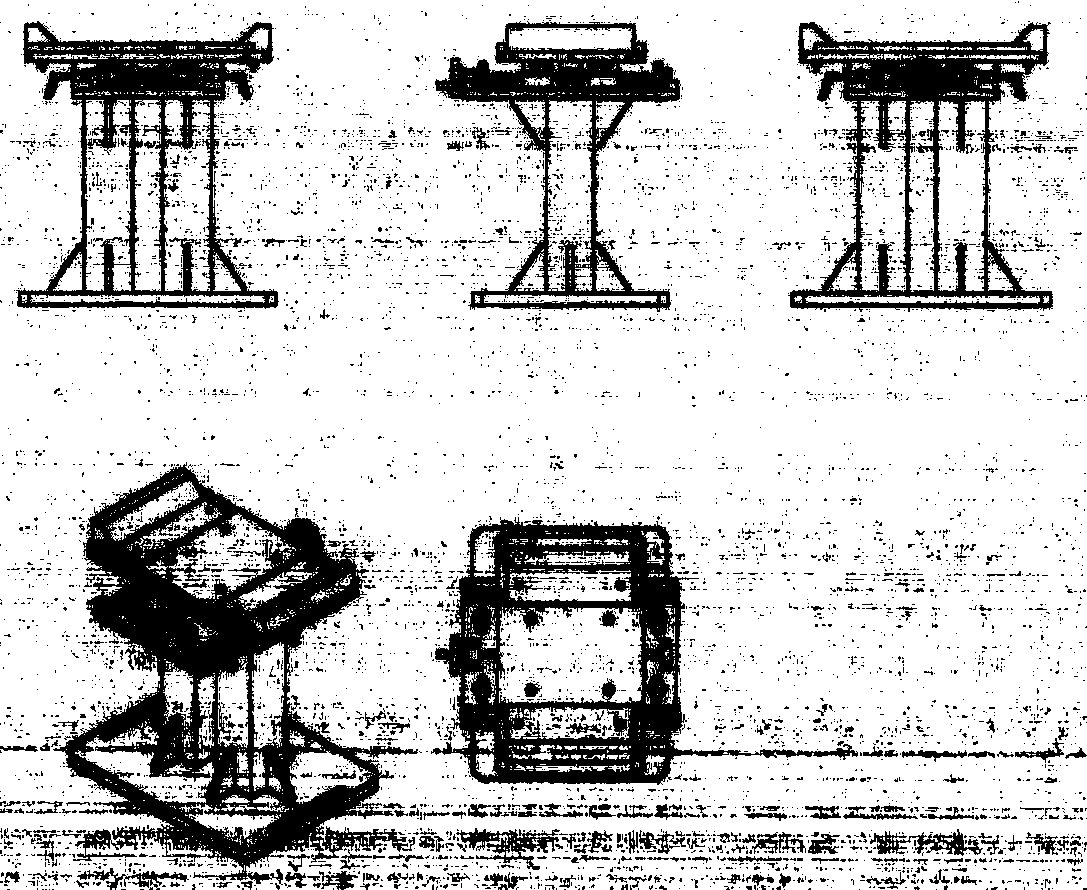

[0016] The self-leveling support includes a total of four tire support devices ( figure 2 ), (used for tire support, so that the measuring arm can penetrate into the bottom of the vehicle for measurement), four jacking devices (used to lift the body Z to release the suspension force), four height gauges ( image 3 ), (through the adaptive structure to capture the height of the four Z-direction building system positions of the car body in real time, and feed back the readings to the control computer), a control cabinet ( Figure 8 ), (including multi-axis motion controller and servo drive and other electrical facilities, the control computer calculates the difference between the measured value of the height gauge and the theoretical position, converts it into the number of pulses, and simultaneously drives four AC servo motors through the multi-axis motion controller for lifting Or descending movement, cycle this process, complete body Z-direction adjustment) and control compu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com