Electric plate leveling hammer

A sheet metal, electric technology, applied in the direction of building, building structure, etc., can solve the problems of sheet falling off or cracking, low frequency of manual knocking, inability to transmit vibration, etc., and achieve the effect of preventing fragmentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

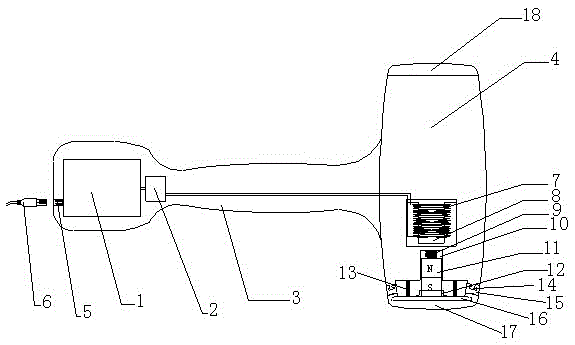

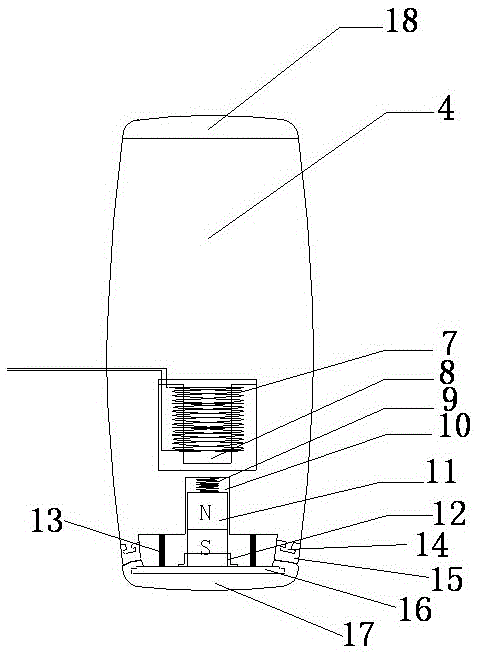

[0016] see Figure 1~Figure 2 : Electric plate leveling hammer includes handle 3, hammer body 4, rechargeable battery pack 1, inverter 2, external wiring socket 5, fixed iron core 8, spring a9, permanent magnet 11, spring b13, rubber buffer body 15, Leveling transmission body 16, leveling head rubber buffer sleeve 17. One end of the handle 3 is fixedly connected with the hammer body 4 to form a T-shaped structure. The rechargeable battery pack 1 and the inverter 2 are arranged in the handle 3, the inverter 2 is electrically connected with the rechargeable battery pack 1, and converts the DC power of the battery pack 1 into AC power. An external wiring socket 5 is provided on the handle 3 , and the external wiring socket 5 can be electrically connected with an external wiring 6 for powering the electric plate leveling hammer and charging the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com