Perpendicular reversing device during cigarette carton transmission

A technology of reversing device and tobacco rod, which is applied in the field of equipment in the tobacco industry, can solve the problems of affecting cam lubrication, occupying a large space, and harsh lubrication environment, so as to prevent rear-end collision of clamping rods, high equipment efficiency and fast collection speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

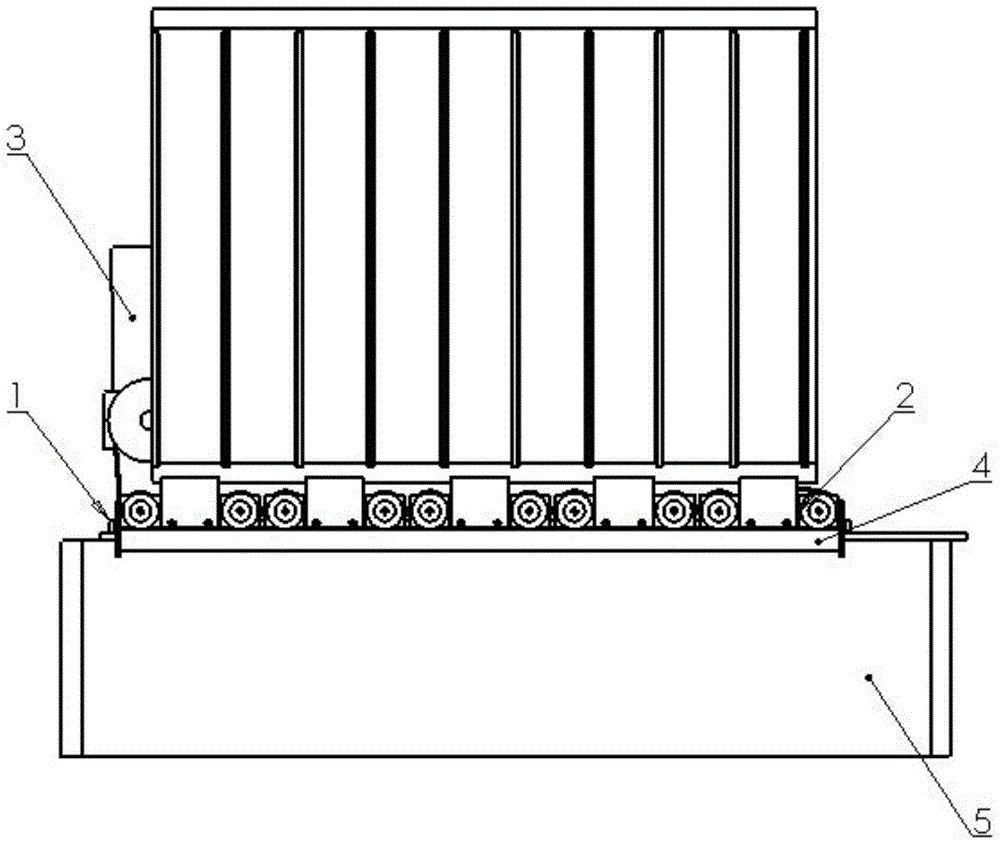

[0039] The vertical reversing device in tobacco rod transmission of the present invention comprises a commutator frame 1 , a commutator strip distributing device 2 , a driving device 3 , a buffer device 4 , and a tobacco rod outlet conveyor belt 5 . The commutator frame 1 is installed at the exit of the low horizontal acceleration section of the tobacco rod conveyor belt to keep it level with the output belt, and the commutator strip matching device 2 is installed on the commutator frame 1 on the side of the low horizontal acceleration section of the tobacco rod conveyor belt At both ends, the driving device 3 is installed on the side end of the low horizontal acceleration section of the tobacco rod conveyor belt, the buffer device 4 is installed on the two narrow side ends of the commutator frame 1, and the tobacco rod outlet conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com