Thin automobile air conditioner

A technology for air conditioners and automobiles, which is applied to vehicle components, air handling equipment, heating/cooling equipment, etc. It can solve the problems of unsatisfactory thickness and size, large wind resistance, and affecting use, and achieves compact structure, convenient manufacture, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

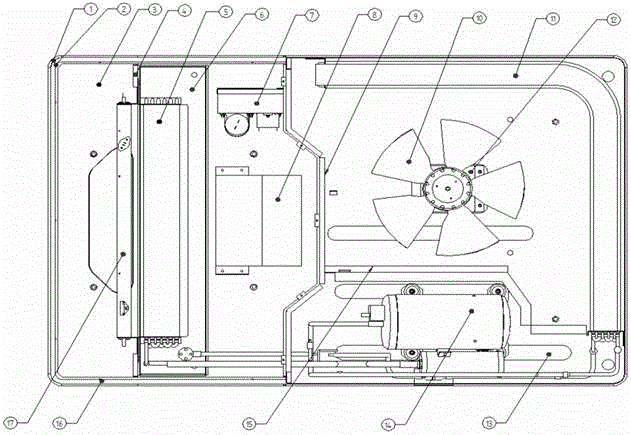

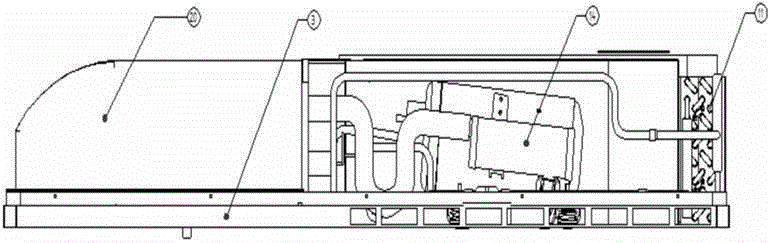

[0046] An ultra-thin automotive air conditioner, comprising a plastic cover 26, a U-shaped installation chassis 3, an electric heater 17, an evaporator 5 junction box 7, an indoor fan 8, a condensing fan 10, a condenser 11, and a horizontal compressor 14 .

[0047] The U-shaped chassis 3 is the bottom plate of the entire air conditioner structure, and a horizontal partition 9 is arranged in the middle to divide the entire air conditioner into an indoor side part located at the front of the car and an outdoor side part located at the rear;

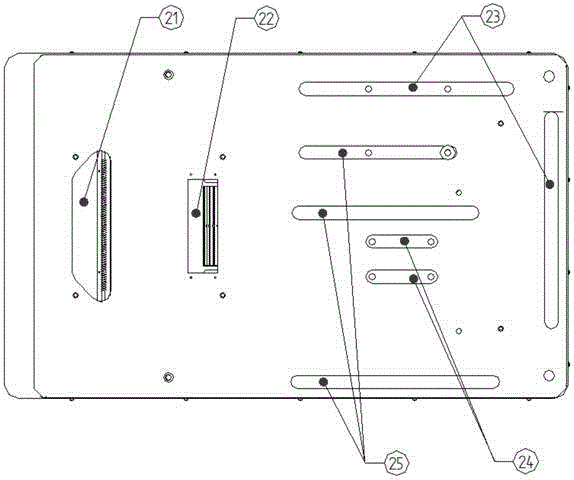

[0048] Indoor side part, install electric heater 17, evaporator 5 and indoor fan 8 successively from front to back, set up air return port 21 on the front side of electric heater 17, and the periphery of return air port 21 has a circle flanging upward; The lower part of the air outlet 22 is provided, and the periphery of the air ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com